Solid state image pickup device and its manufacturing method

A solid-state imaging device and solid-state image pickup technology, which are used in image communication, electrical solid-state devices, televisions, etc., can solve the problems of easy cracking of solid-state image pickup components, hindering productivity improvement, and decreasing productivity, saving manpower, Realize the effect of miniaturization and simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

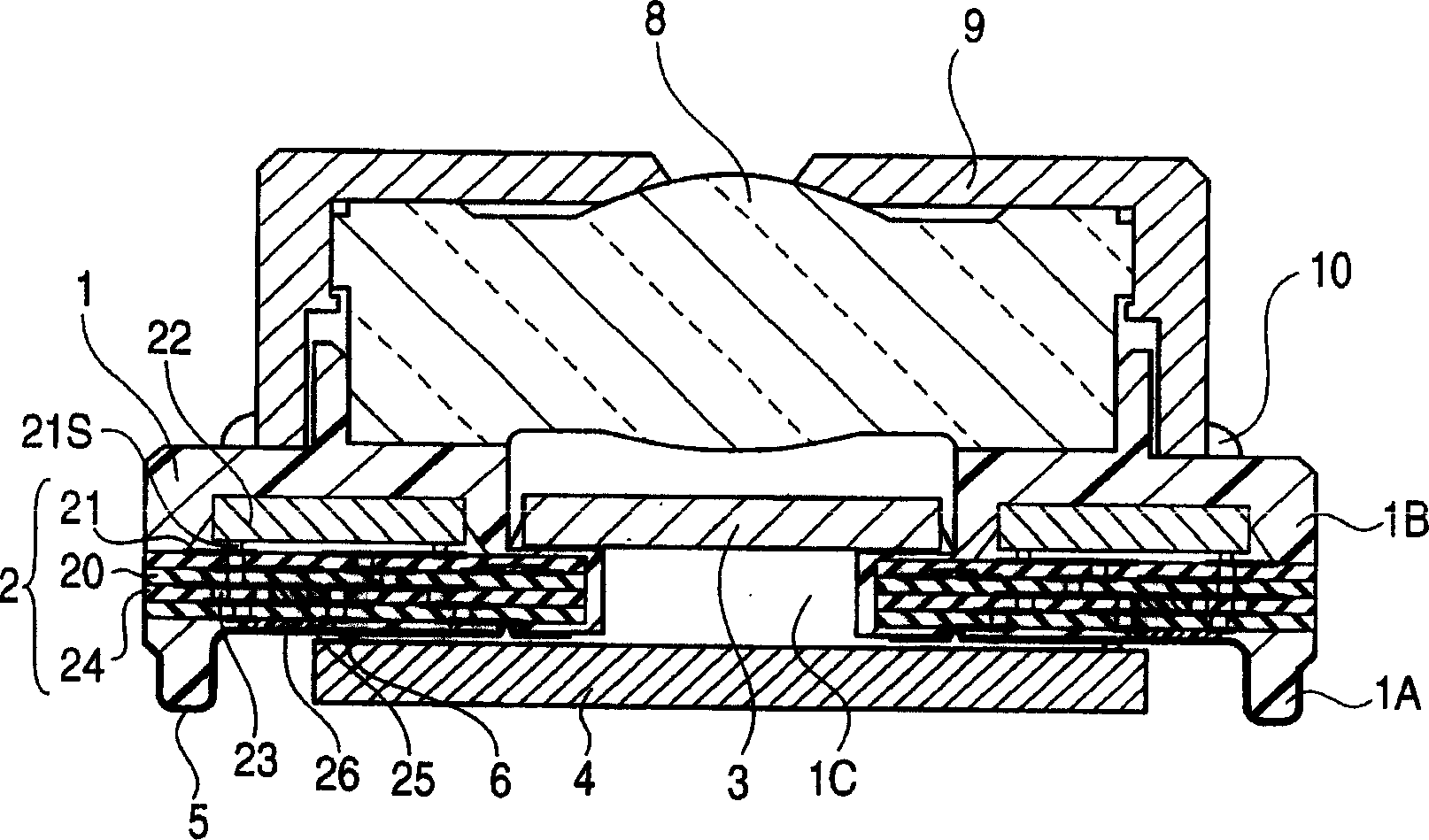

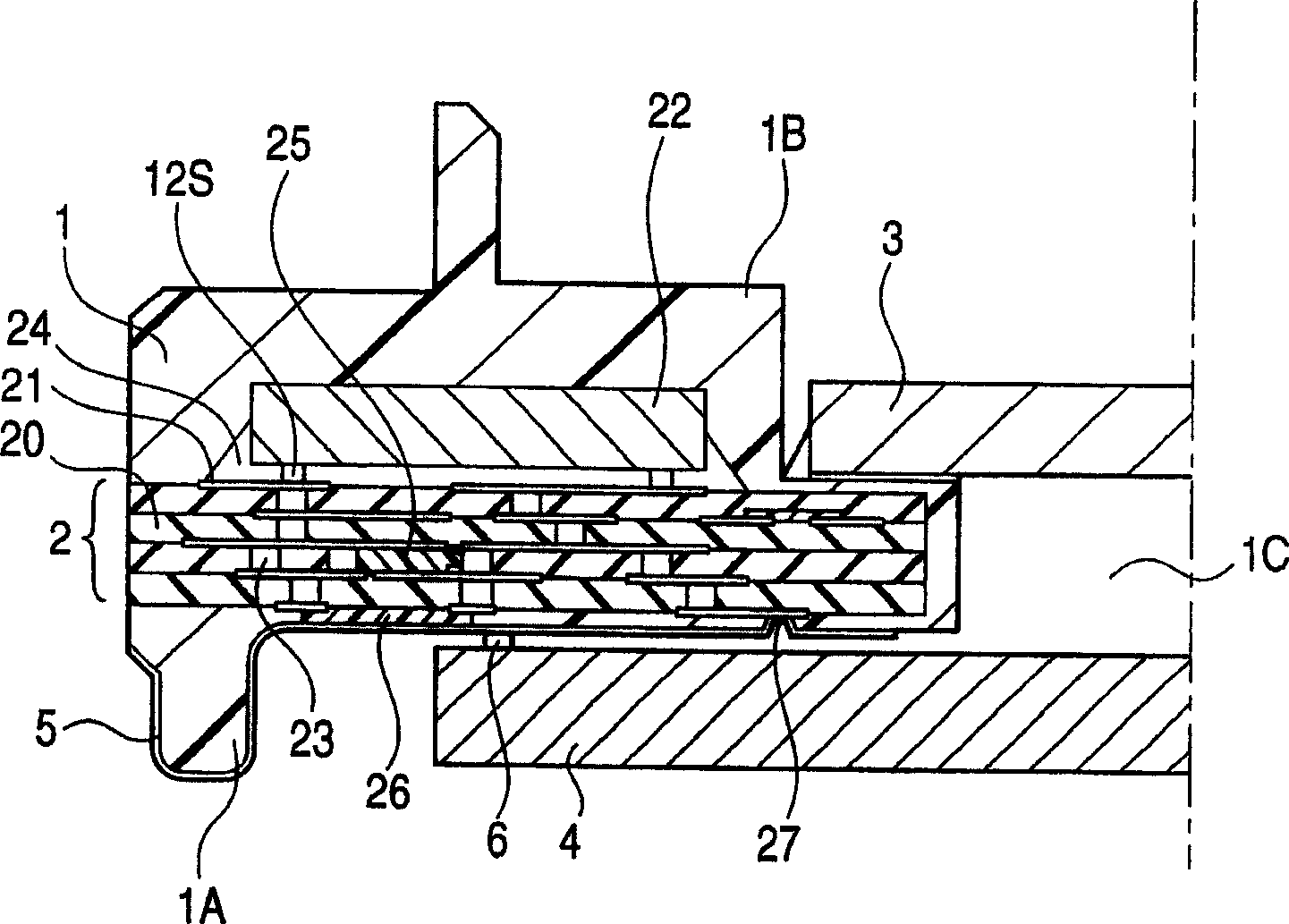

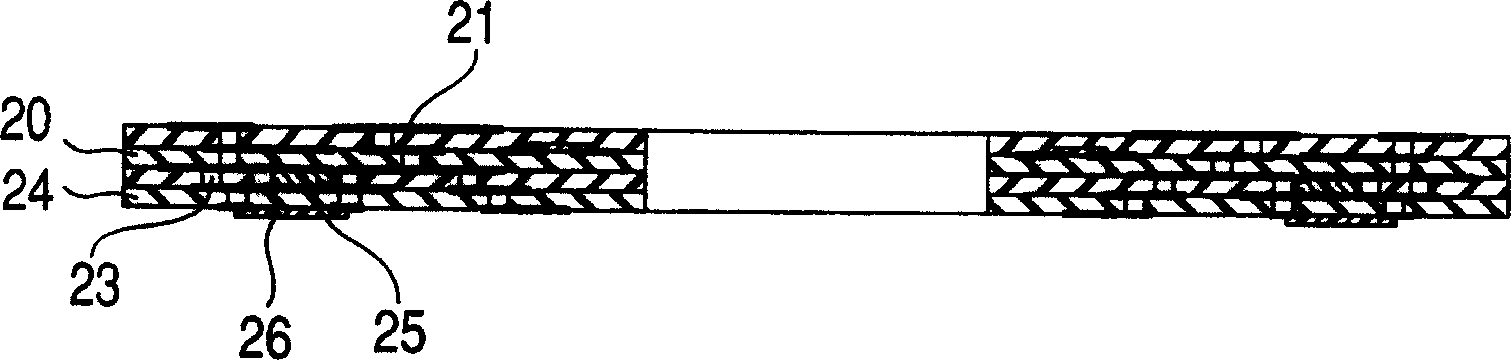

[0092] figure 1 and 2 is a view of the main body portion of the solid-state imaging device of the first embodiment of the present invention.

[0093] In this solid-state imaging device, in the molding process of the structural member 1 on which the solid-state image pickup element is mounted, the multilayer wiring board 2 and the signal processing circuit chip DSP formed on the first surface of the multilayer wiring board 2 22 are sealed together into the structure 1 made of insulating polyphthalamide resin. In addition, a multilayer wiring board is used as a service circuit board of a ceramic substrate forming a base member whose thermal expansion coefficient is significantly smaller than that of a resin constituting the structural member. The structural member 1 has a through-hole portion 1C. The plate-shaped member constituting the optical filter 3 is mounted to the structural member 1 including the processing circuit chip DSP 22 therein so as to face the through-hole p...

Embodiment 2

[0115] Figure 4 is a view of a main body portion of a solid-state imaging device according to a second embodiment of the present invention.

[0116] In the first embodiment, the optical filter 3 is mounted to a multilayer wiring board. In contrast, in the second embodiment, the ceramic substrate constituting the multilayer wiring board is made of light-transmitting ceramics, and a required thin film is formed on the surface as the polyrefringence material 20S used as an optical filter. The multilayer wiring board sealed into the structural member is constructed in the following manner. A polyrefringence material 20S is used as an insulating base, and the multilayer wiring structure 2M is formed so as to have a ring shape in a peripheral area except for a corresponding area to the through-hole portion 1C. The multilayer wiring structure 2M is placed in an injection mold, and then injection molded to seal the central region of the multilayer wiring structure 2M with a structu...

Embodiment 3

[0121] Figure 6 and 7 is a view of a main body portion of a solid-state imaging device according to a third embodiment of the present invention. Figure 7 is along Figure 6 A cross-sectional view taken along the line A-A.

[0122] In this solid-state imaging device, in the molding process of the structural member 101 on which the solid-state image pickup element 104 is mounted, the ceramic substrate 102g and the circuit part 102 of the multilayer structure formed on the film carrier 120F used as a flexible substrate are separated from the The signal processing circuit chip (DSP) 122 formed on the first surface of the ceramic substrate 102g is sealed together with the insulating polyphthalamide resin through the through hole (not shown) opened on the ceramic substrate 102g. In the structural member 101. In addition, a ceramic substrate 102g is used as a fixing member, and the coefficient of thermal expansion of the ceramic substrate 102g is remarkably smaller than that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com