Electric startup and stacked plate type automatic thermal reforming device

An automatic thermal reforming, stacked plate technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of long start-up time, bulky, complex structure, etc. The effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

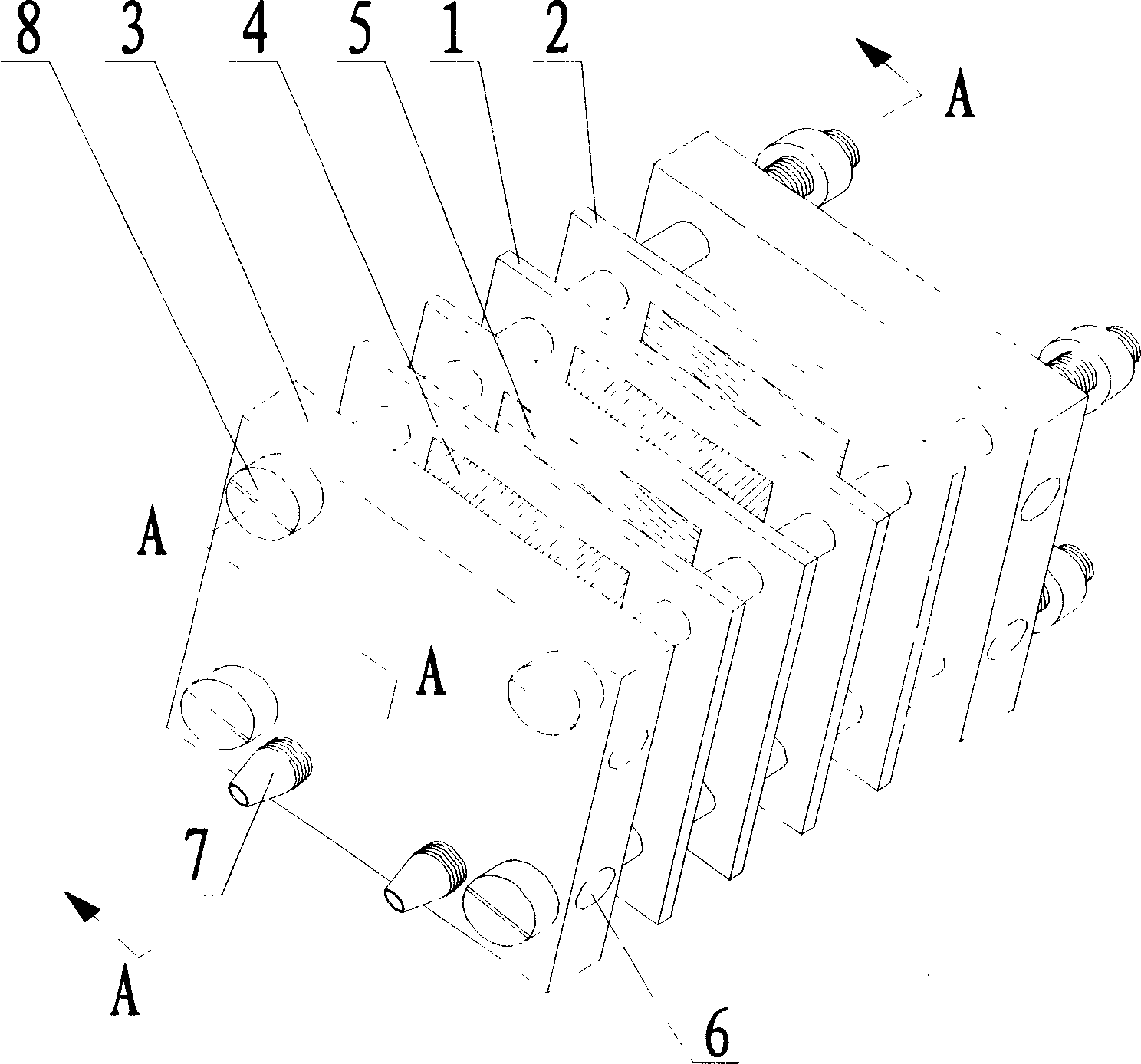

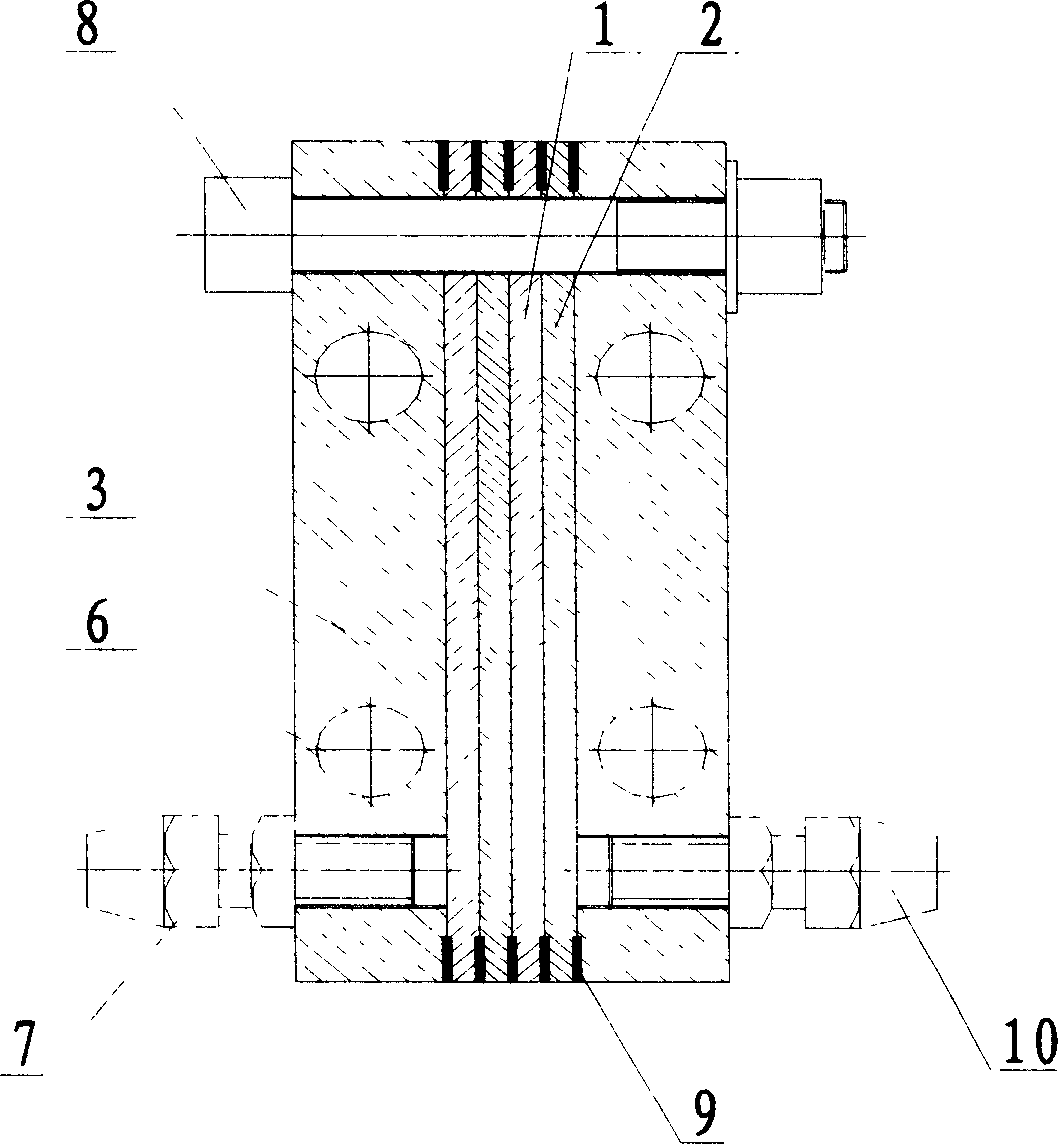

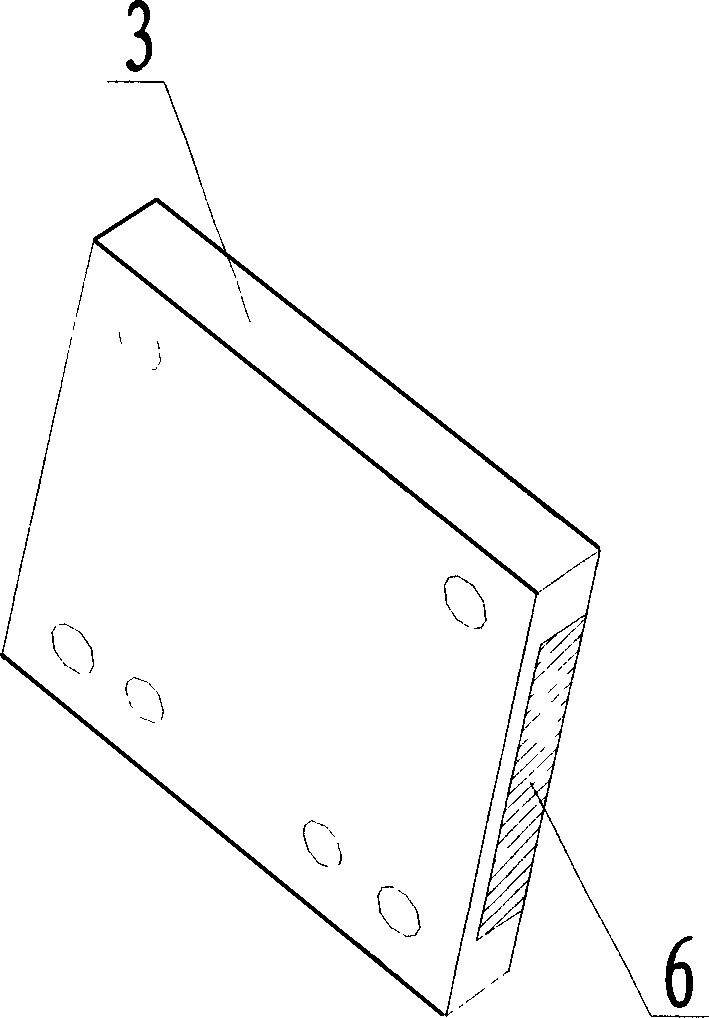

[0020] like figure 1 , 2 As shown, the electric stacked plate automatic thermal reformer mainly includes a steam reforming reaction plate 1, a partial oxidation reforming reaction plate 2, a fixed heating plate 3, a catalyst carrier 4, a catalyst carrier 5, an electric heating body 6, and a reaction gas Inlet 7, fixing bolt 8, sealing washer 9 and reformed gas outlet 10. In this embodiment, two square steam reforming reaction plates 1 and two square partial oxidation reforming reaction plates 2 are alternately stacked together, located between two fixed heating plates 3, and flow channels are formed between each plate , sealed by sealing washer 9, and connected together by fixing bolt 8. Two reactive gas inlets 7 are installed on the fixed heating plate 3 at one end, and two reformed gas outlets 10 are installed on the fixed heating plate 3 at the other end. Two heating rods used as electric heating bodies 6 are respectively installed on the fixed heating plate 3 . The ste...

Embodiment 2

[0024] The steam reforming reaction plate 1 and the partial oxidation reforming plate 2 of the automatic thermal reforming reaction system are a pair. The steam reforming reaction plate 1 and the partial oxidation reforming plate 2 are circular, and the fixed heating plate 3 is also circular. The electric heating body 6 is a square heating block, and the others are the same as in Embodiment 1.

Embodiment 3

[0026] There are 5 pairs of steam reforming reaction plates 1 and partial oxidation reforming plates 2 . The steam reforming reaction plate 1 and the partial oxidation reforming plate 2 are elliptical, and the fixed heating plate 3 is also elliptical. The electric heating body 6 is a U-shaped heating tube. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com