Regulated pump

A pump casing and pressure zone technology, applied in the field of oil pumps of internal combustion engines, can solve problems such as energy consumption and emission, and achieve the effects of reducing pulsation and improving control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

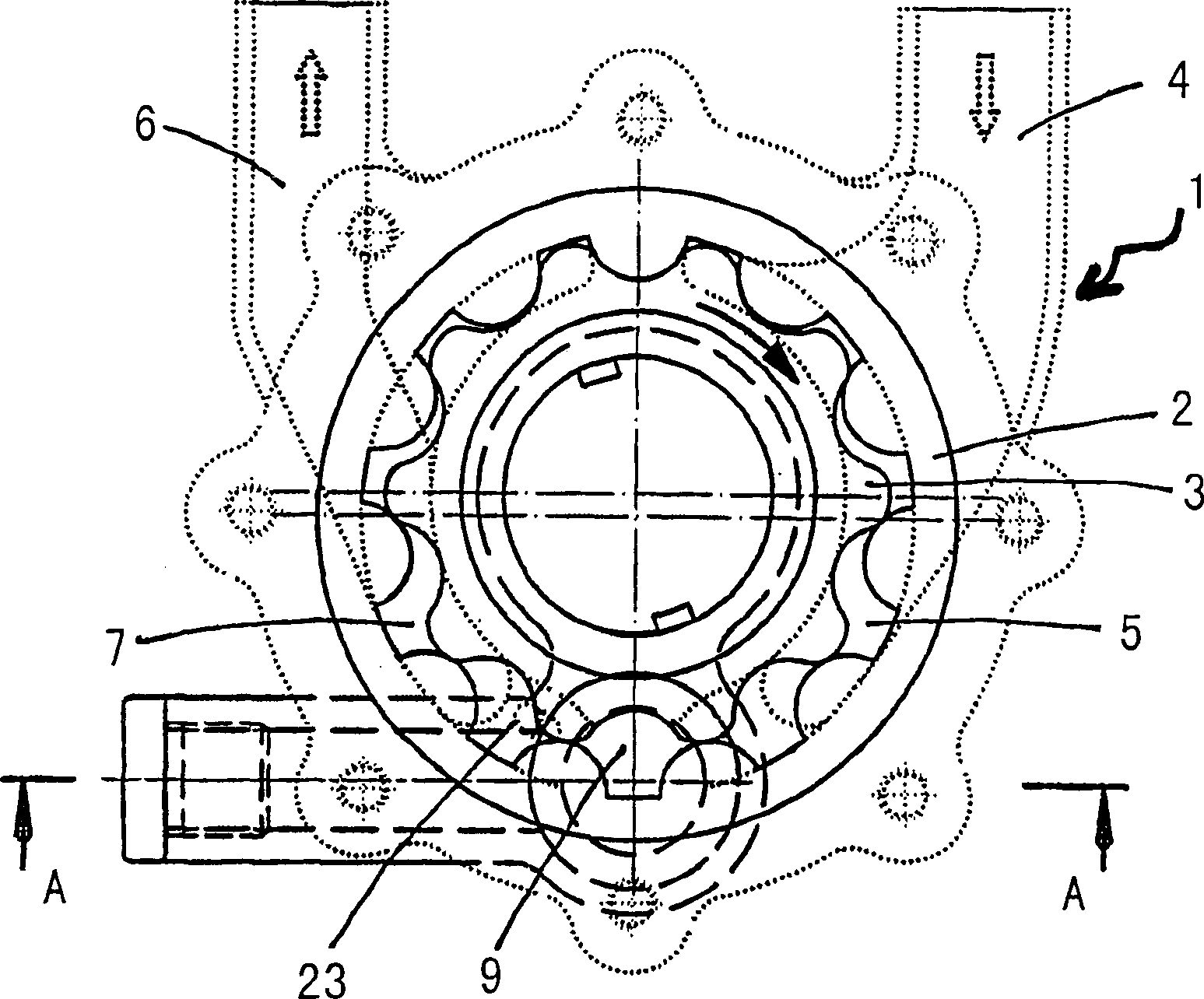

[0040] figure 1 A top view is shown of a pump 1 , in particular an oil pump for an internal combustion engine, which is equipped with a rotor arrangement designed as a cycloidal rotor, which comprises an outer rotor 2 and an inner rotor 3 . The pump 1 has an inlet 4 to a suction area 5 and an outlet 6 to a pressure area 7 . Both areas are designed to be kidney-shaped.

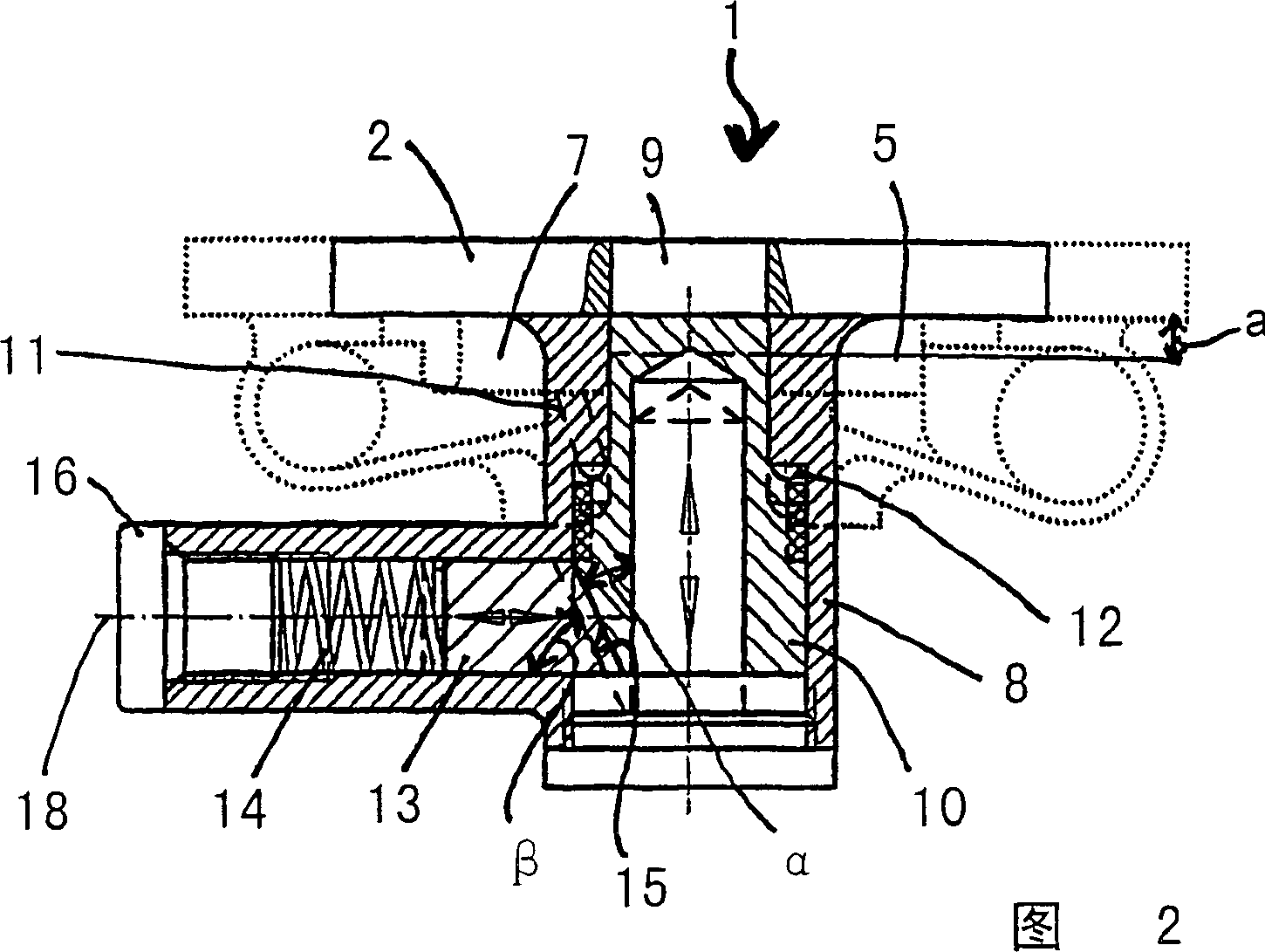

[0041] Fig. 2 shows according to the pump 1 of the present invention along figure 1 A section of the line A-A in the center. A suction zone 5 and a pressure zone 7 are arranged on the pump housing 8 . The suction area 5 and the pressure area 7 are sealably separated from each other by an axially displaceable control piston 10 delimiting a delivery chamber 9 . The pressure zone 7 has a pressure regulating channel 11 which is connected to a collar 12 of the control piston 10 . The control piston 10 cooperates at its end facing away from the delivery chamber 9 with a spring pin 13 arranged at right angles to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com