Quadratic core of lithium ion battery and fabricating method

A lithium-ion battery, square technology, applied in the manufacture of electrolyte batteries, secondary batteries, and final product manufacturing, etc., can solve the problems of large influence of subsequent processes, difficult process, heavy workload, etc., to improve production efficiency and simplify products. Process, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

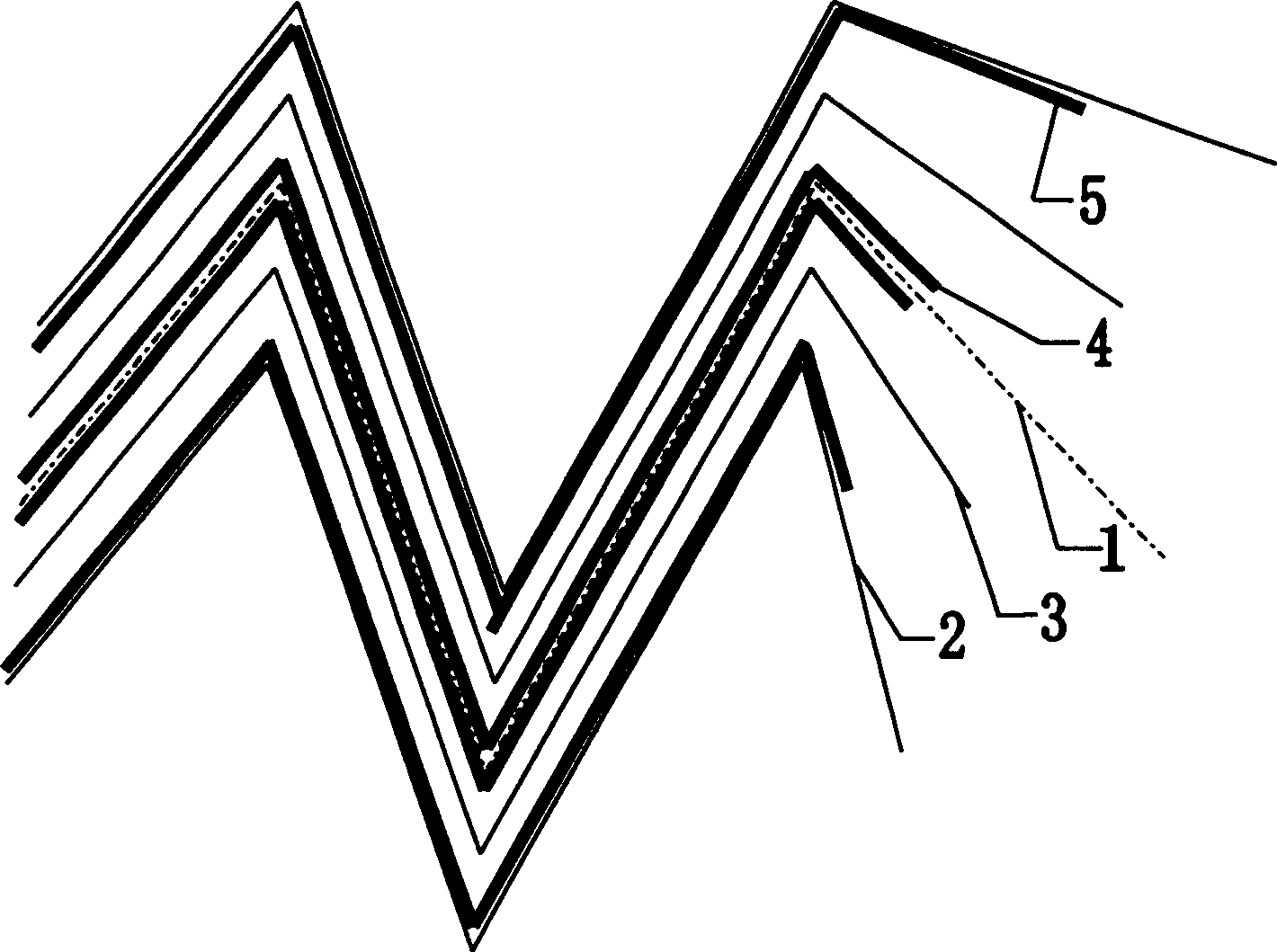

[0014] Refer to attached figure 1 , the structure of the square lithium ion battery core is negative electrode copper foil 1; positive electrode aluminum foil 2; diaphragm 3; negative electrode active material 4; positive electrode active material 5.

[0015] A method for manufacturing a square lithium-ion battery core, using a positive electrode aluminum foil 2 with double-sided positive electrode active materials 5 and a negative electrode copper foil 1 coated with negative electrode active materials 4 at intervals on one side, and using a slitting machine to cut according to the designed battery core height For the above two kinds of plates, place the positive aluminum foil 2 between the two layers of separators 3, and stick the surface of the two negative electrode copper foils 1 with the negative electrode active material 4 on the other two sides of the two layers of separators 3 so that they are stacked together. The respective offsets of the positive and negative tabs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com