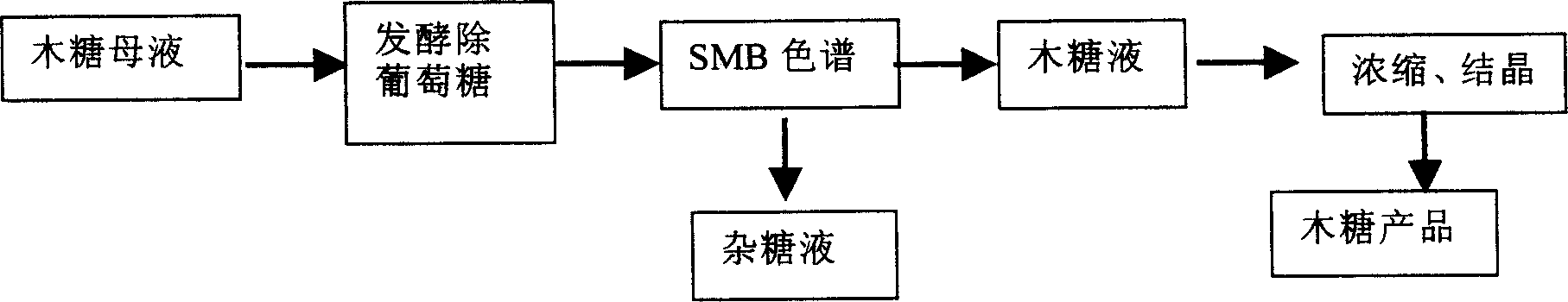

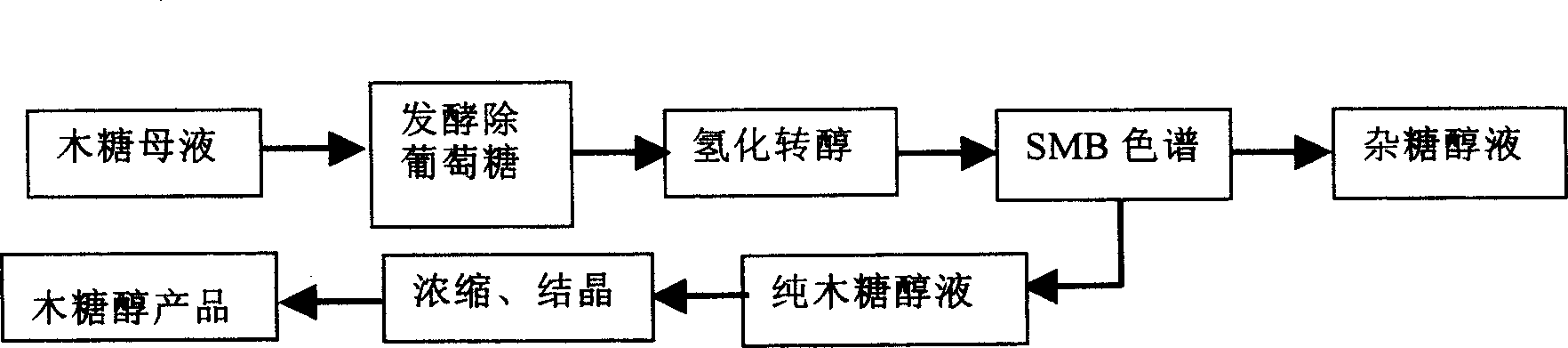

Process for extracting xylose and xylitol from a xylose mother liquor or a xylose digest

A technology for xylose hydrolyzate and xylose mother liquor, which is applied in the field of preparation of high-purity xylose and xylitol, can solve the problems of inability to crystallize and recover xylose, reduce the economic benefit of xylose production, etc. The effect of low cost and good adsorption and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] The feed liquid is xylose mother liquor, wherein the refractive concentration is about 63% (wherein glucose ~ 15%; xylose ~ 50%; galactose ~ 6%, arabinose ~ 22%). The refractive concentration is about 56% (glucose ~ 2%; xylose ~ 60%; galactose ~ 10%, arabinose ~ 26%), this mother liquor is added to the hydrogenation reactor, and 5% Raney nickel catalyst is added, After the hydrogen pressure in the reactor reaches 50 bar, heat to 125° C., keep the pressure, and stop the hydrogenation after reacting for 8 hours. The reducing sugar content is less than 0.1% as measured by the Bertrant method to obtain the xylitol mother liquor. Its refractive concentration is 55%, and its xylitol content is about 62%.

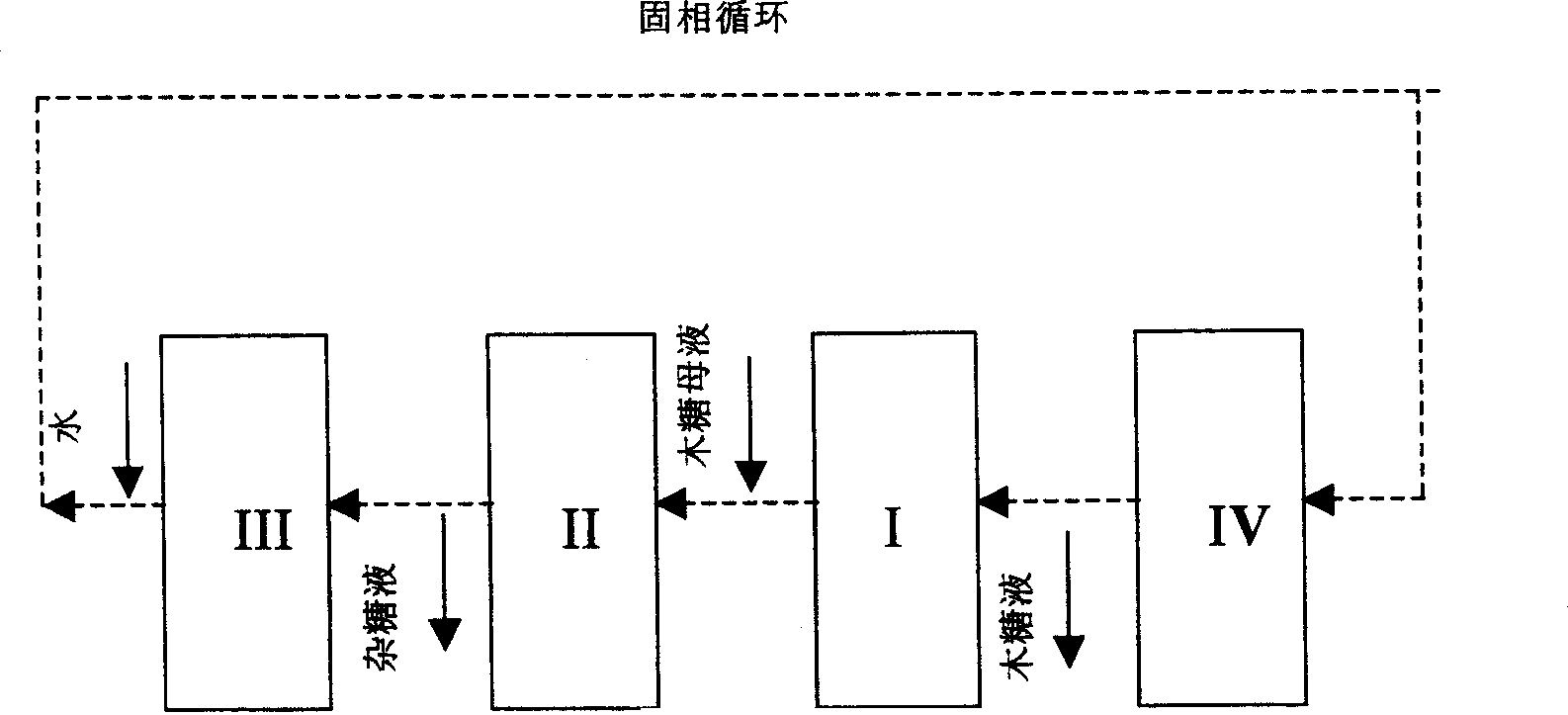

[0052] The operating conditions of the simulated moving bed are as follows: the separation temperature is 75°C, the system pressure is 1.0Mpa, the feed rate of the feed liquid is 1L / h, and the feed rate of the elution water is 2.5L / h, and the feed reaches equilibrium after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com