Aluminium based powder core wire

A technology of powder core wire and powder core wire, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of less intermetallic compounds, low density of aluminum powder, and limitation of addition amount, and achieve the application The effect of broad prospects and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

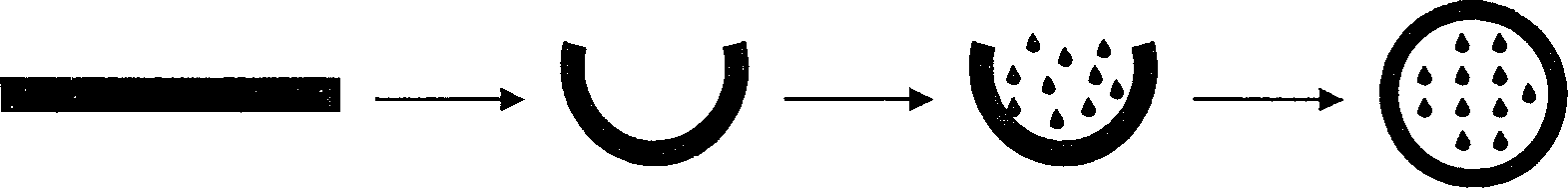

[0015] 1. Preparation of aluminum-based powder core wire

[0016] A 10×0.6 (width 10mm, thickness 0.6mm) aluminum strip is selected. First roll it into a U shape, take Fe, Ni, Ti, B, and RE and mix them uniformly, then add the mixed powder into the U-shaped Al belt groove, the filling rate is 40-60%, and close the U-shaped groove, Coat it with mixed powder. Finally, the diameter is reduced step by step through the wire drawing die until the required diameter. The schematic diagram of the preparation process is shown in the attached figure 1

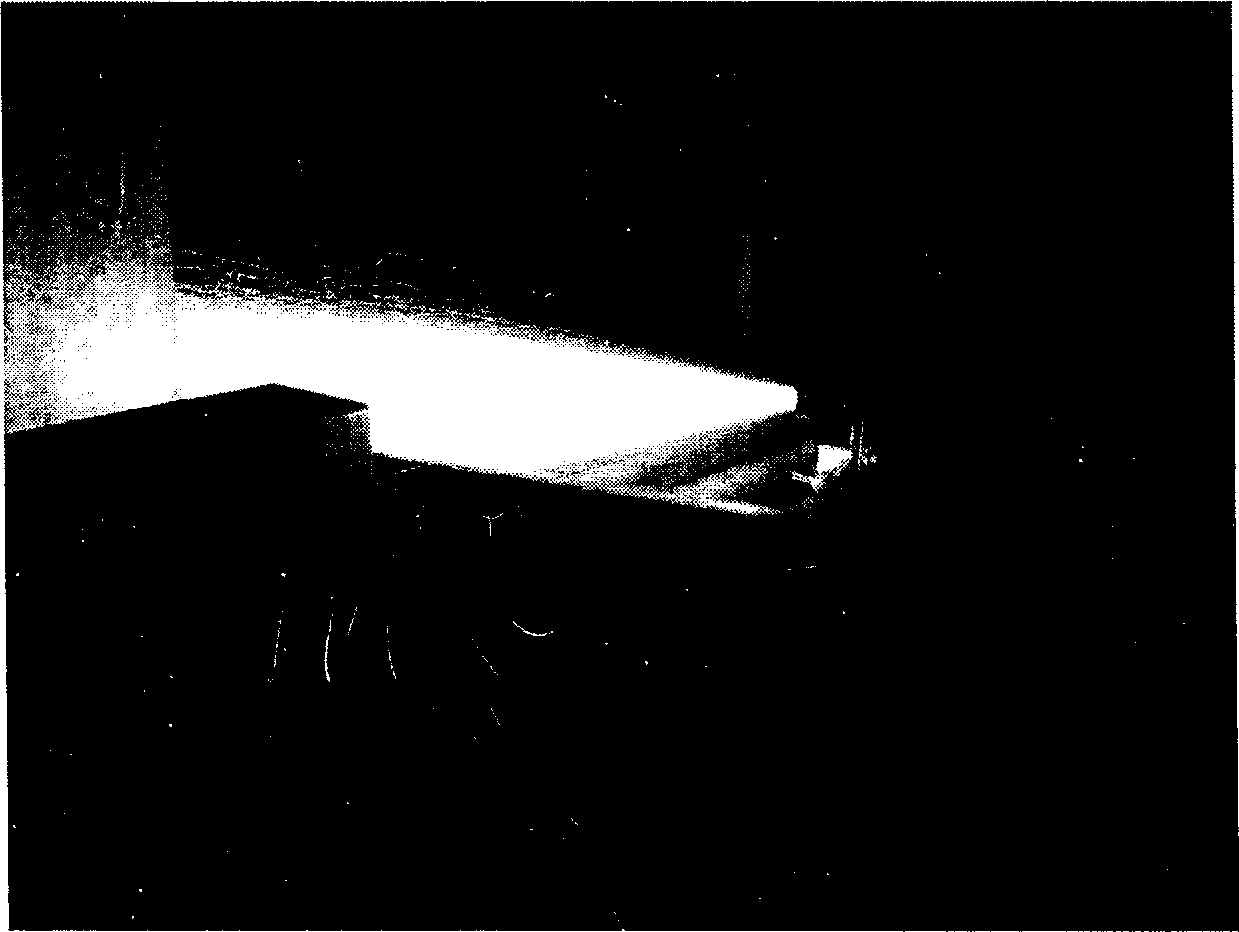

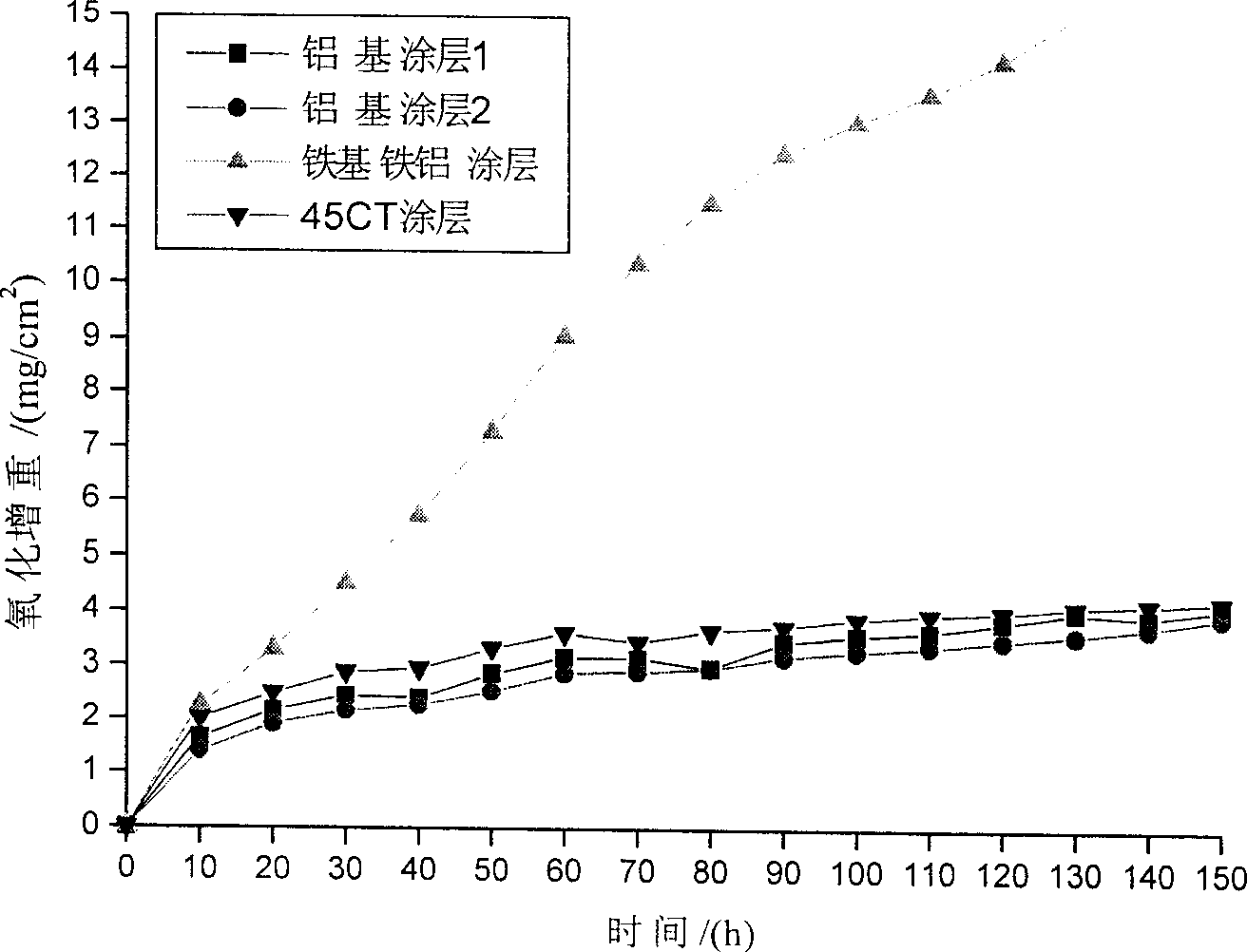

[0017] 2. Preparation of Aluminum-Based Coating

[0018] The aluminum-based coating is prepared by high-speed arc spraying. The spraying process parameters are: spraying current 100-120A, spraying voltage 32-36V, spraying gas pressure 0.5-0.7MPa, and spraying distance 150-180mm. attached figure 2 On-site photos of high-speed arc spraying for aluminum-based powder core wire materials, by figure 2 It can be seen that the prepared al...

Embodiment 1

[0019] Example 1 The aluminum-based powder core wire material of this example was prepared by using the above-mentioned preparation method of the aluminum-base powder core wire material, and its composition is shown in formula 1 in appended table 1.

Embodiment 2

[0020] Example 2 The aluminum-based powder core wire material of this example was prepared by using the above-mentioned preparation method of the aluminum-base powder core wire material, and its composition is shown in formula 2 in attached table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com