Automatic detector for spring leaves used for geophone

A geophone and spring sheet technology, applied in the field of detection instruments, can solve the problems of inaccurate measurement of flat spring sheets, low measurement efficiency, poor repeatability, etc., and achieve the effects of high degree of automation, improved production efficiency, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

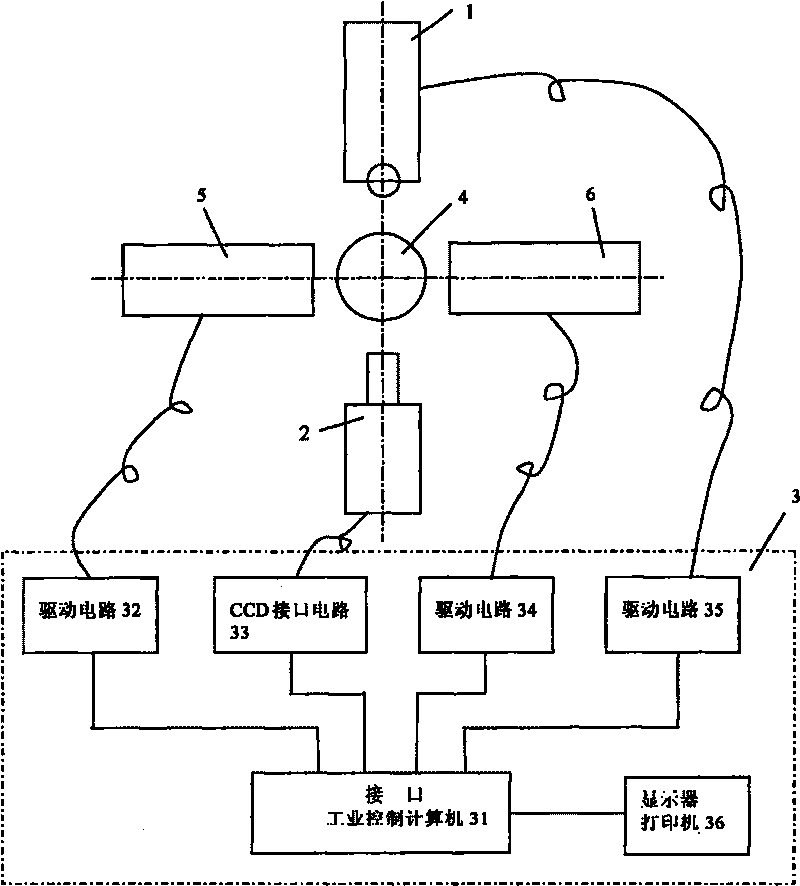

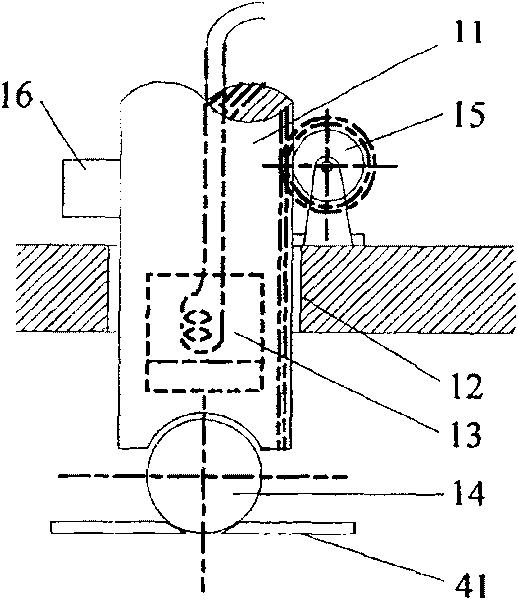

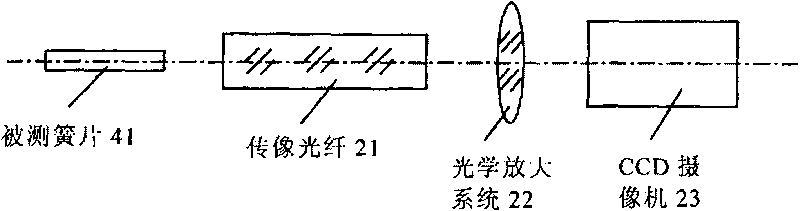

[0024] Such as figure 1 , 2 As shown, the present invention includes an electromagnetic weight applying mechanism 1, a CCD displacement measuring unit 2, a drive and control system 3, a leaf spring measuring platform 4, a leaf spring feeding mechanism 5 and a leaf spring unloading mechanism 6, and a leaf spring feeding mechanism 5 The spring piece 41 is sent to the spring piece measuring platform 4, and the electromagnetic weight applying mechanism 1 sends the load force to the top of the spring piece 41 on the spring piece measuring platform 4, so as to add a suitable measuring force, and the CCD displacement measuring unit passes through The CCD camera system and the optical amplification system measure the displacement and deformation of the spring sheet 41 after loading, and send it to the drive and control system 3 to automatically control the output signal of the CCD displacement measurement unit 2, and display the measurement results, and then the spring sheet is lowere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com