Method for making electric control zooming and optical imaging system

A technology of an optical imaging system and a manufacturing method, which is applied in the field of electronically controlled zoom optical imaging systems, can solve problems such as unfavorable system integration and miniaturization, slow zoom speed, and bulky volume, and achieve quantity saving, short response time, and ease of use. integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0019] Implementation steps of the present invention are:

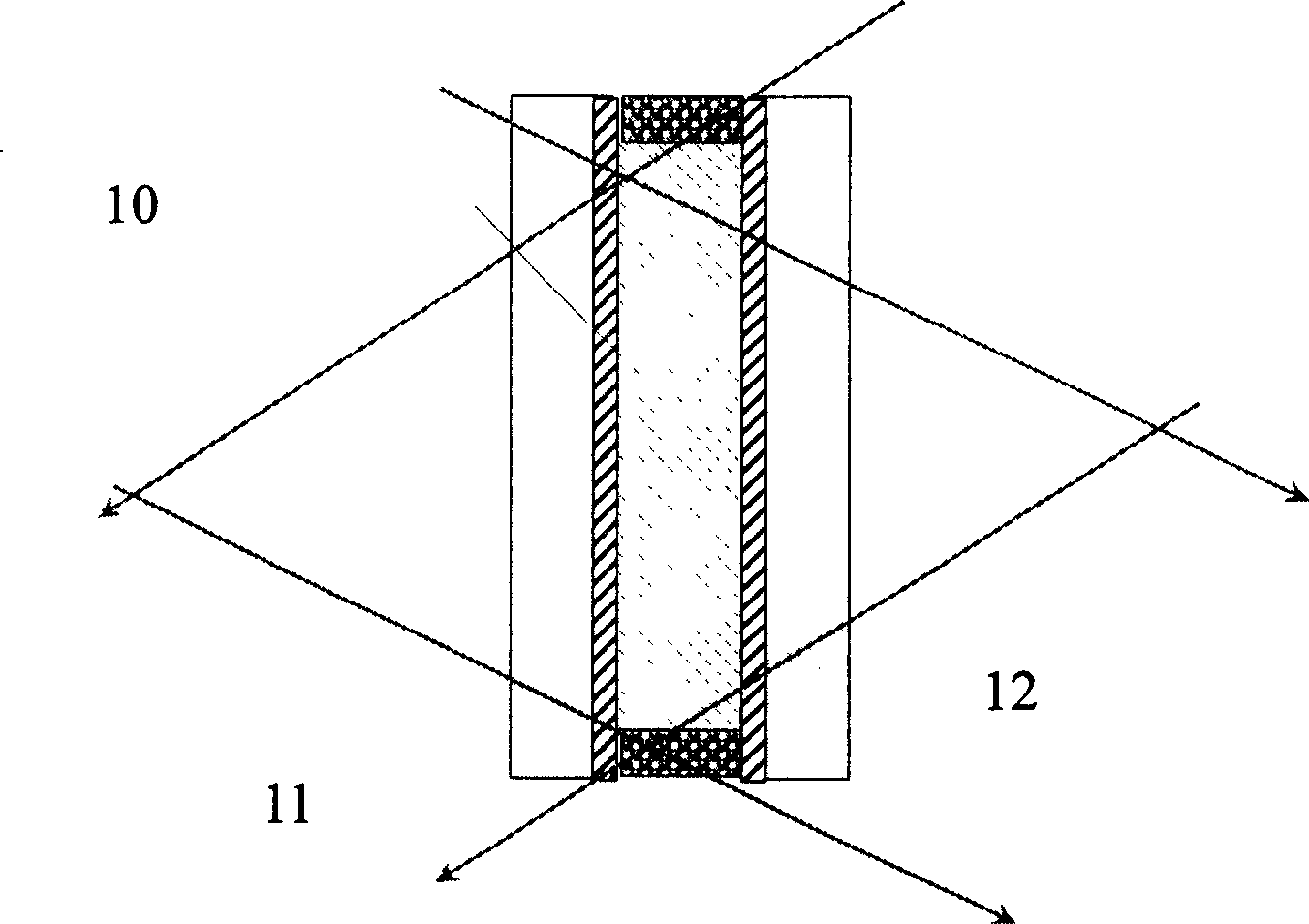

[0020] 1. Preparation of liquid crystal grating element: it includes two glass substrates coated with a conductive layer, and a recording layer composed of 5-10μ PDLC material is filled in the glass substrate;

[0021] 2. Design the holographic optical path with the laser holographic method, and make a holographic lens on the recording layer. The lens effect can be erased under the action of an AC electric field of 5-50V;

[0022] 3. Design different holographic optical paths, and use the same method to make holographic diffraction lenses with different focal lengths;

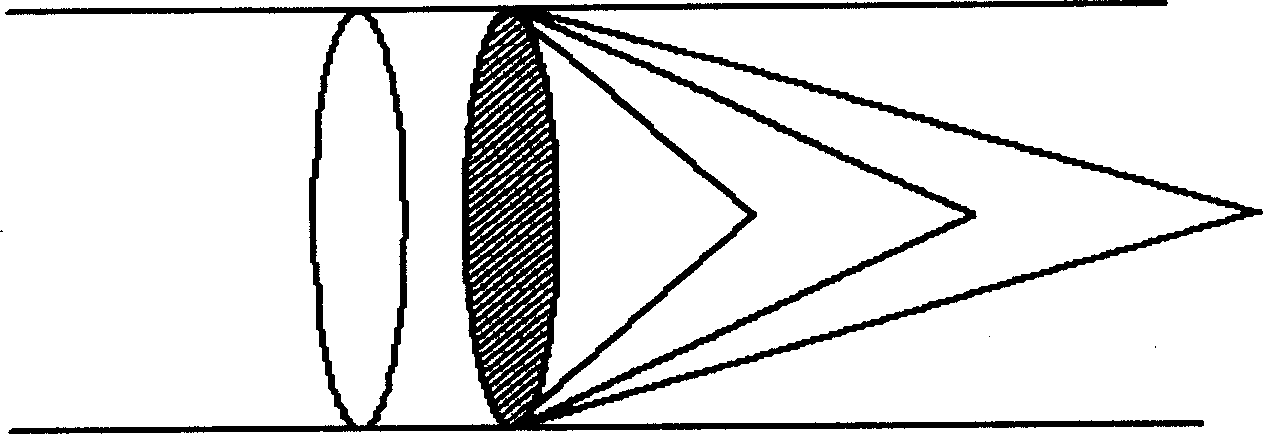

[0023] 4. Superimpose, combine and integrate a group of lenses with different focal lengths into an optical imaging system;

[0024] 5. The computer program calculates and controls the electric field of a single zoom lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com