Method for making crystal honey

A manufacturing method and honey technology, which are applied in food preparation, application, food science and other directions, can solve the problems of low transparency of honey, flocculent precipitation and turbidity of products, and achieve the effect of improving light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Preparation of Crystal Honey

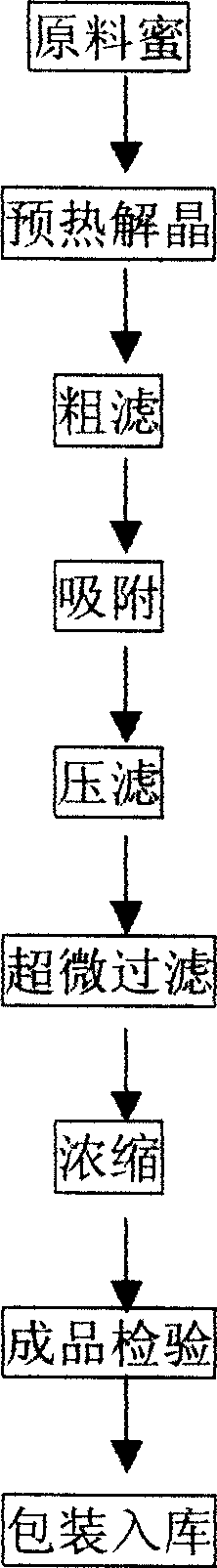

[0018] The preparation process follows figure 1 The above steps are carried out. Take 100kg of raw materials and place them in a container. After preheating and decrystallizing at 35-65°C, filter with filter cloth to remove impurities, add 0.1-1kg of adsorbent, and put them under the condition of 40-65°C Stir under low pressure for 20-120 minutes, press filter with 60-280 mesh filter cloth to remove adsorbed substances, and then filter through 0.15-1.2μ microporous membrane ultrafiltration to remove impurities and concentrate under reduced pressure to make the water content of honey reach below 23% , cooled and packed to get the finished product.

[0019] 2. Determination of light transmittance (T%) of crystal honey

[0020] The clarity of honey is evaluated by measuring the light transmittance of honey.

[0021] Accurately weigh 5g of the honey sample into a 50ml beaker, accurately add 10ml of distilled water, stir to dissolve it co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com