Low-power consumption permanent magnetic offset mixed radial magnetic bearing

A permanent magnet bias and hybrid radial technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of large reluctance, large volume, and large power consumption of permanent magnets, and reduce copper consumption and power consumption. Consumption, the effect of low iron consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

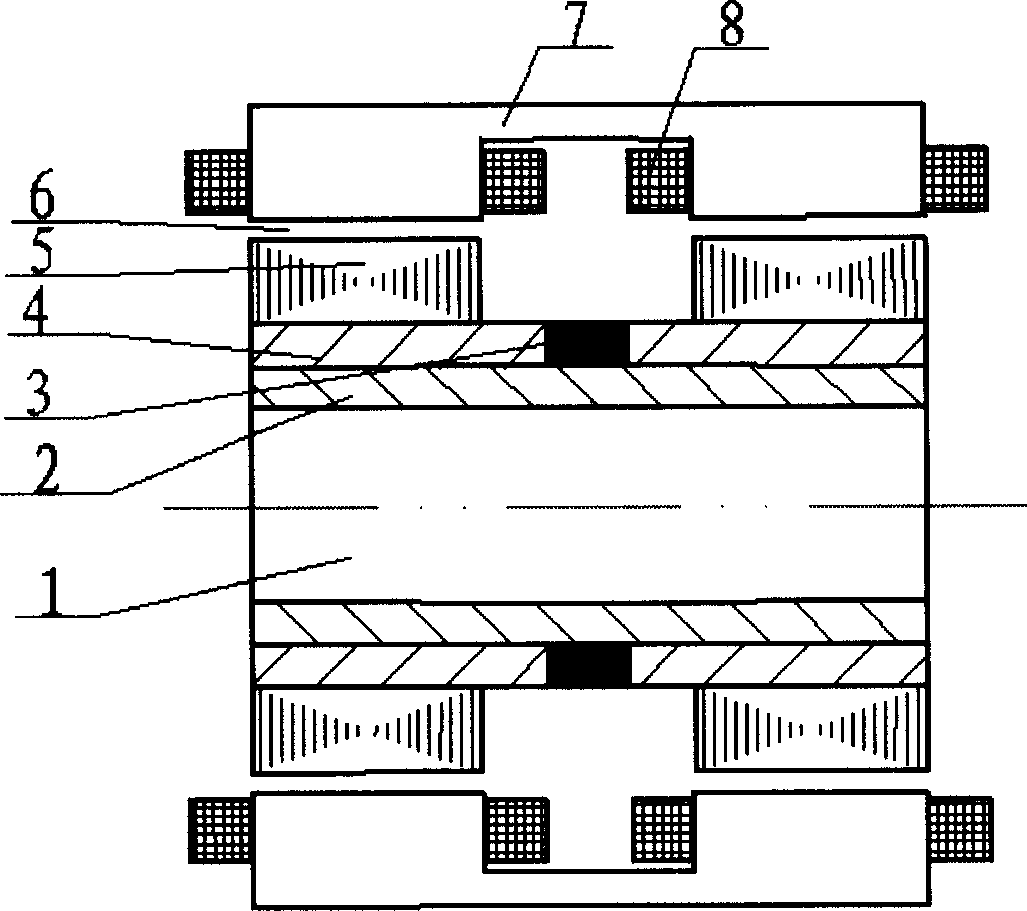

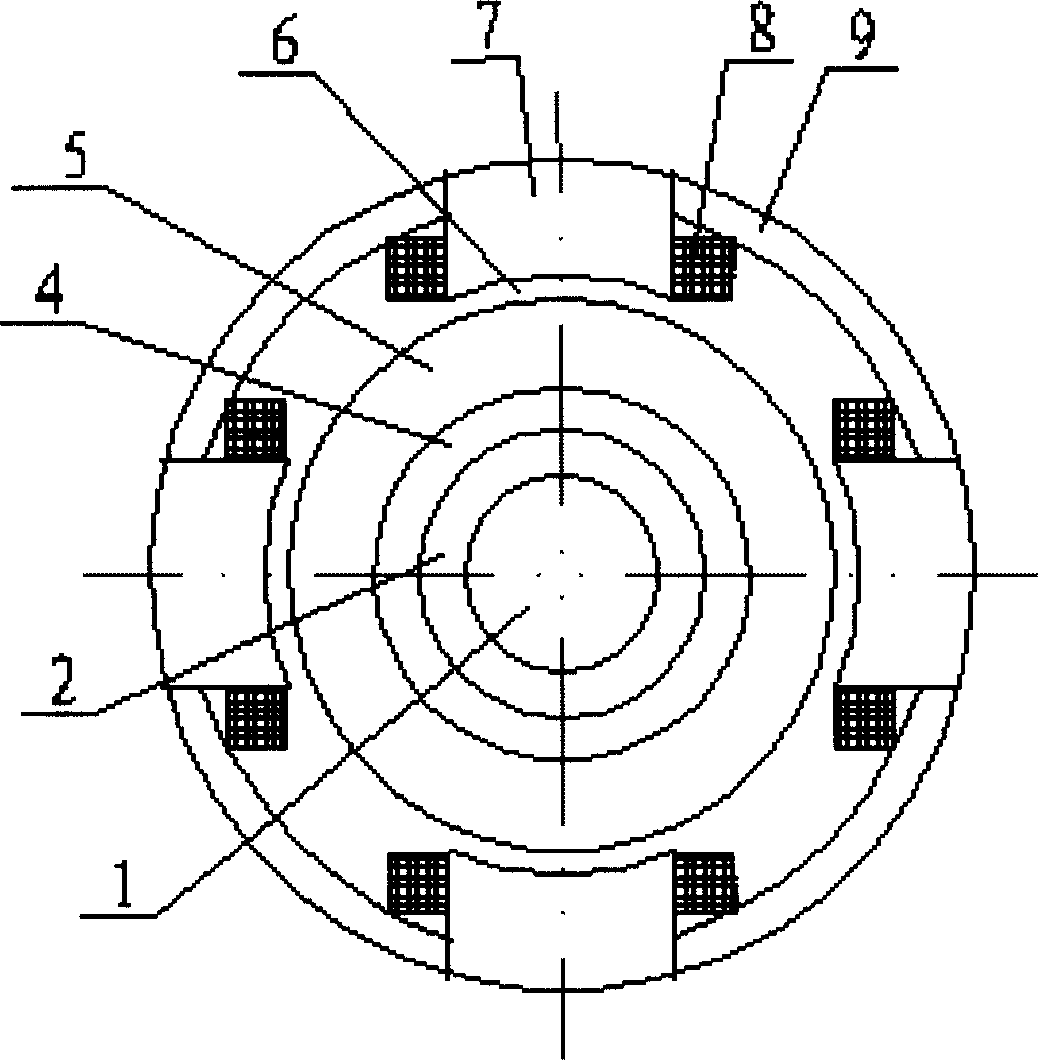

[0009] Such as figure 1 , figure 2 As shown, the present invention generally consists of left and right sets of stators and rotors. There is an air gap 6 between the stators and rotors. Each stator core yoke 7 spans the left and right ends and forms a magnetic pole at each end. Four stator core yokes 7 Orthogonally placed, respectively connected in two sections to form 4 magnetic poles of ±X axis and ±Y axis, such a magnetic bearing has 8 magnetic poles in total, and the left and right groups are respectively 4 magnetic poles. Between the stator core yoke 7 in the X-axis direction and the Y-axis direction is the stator pole spacing magnet 9, and the stator coil 8 is wound on the stator core yoke 7; the rotor includes a rotating shaft 1, a permanent magnet 3, a magnetic sleeve 4, and a rotor core 5. On the outside of the rotating shaft 1 are two magnetically conductive magnetic sleeves 4 and permanent magnets 3. The two magnetically conductive sleeves 4 sandwich the permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com