Electric medicine kettle capable of regulating residual medicine dose

A medicine pot and medicine dosage technology, which is applied in the direction of making medicine into a special physical or taking form of the device, can solve the problems that the user cannot control the intervention, the remaining medicine varies greatly, and the remaining medicine cannot be well controlled. Achieve the effect of low cost of improvement, simple structure and perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

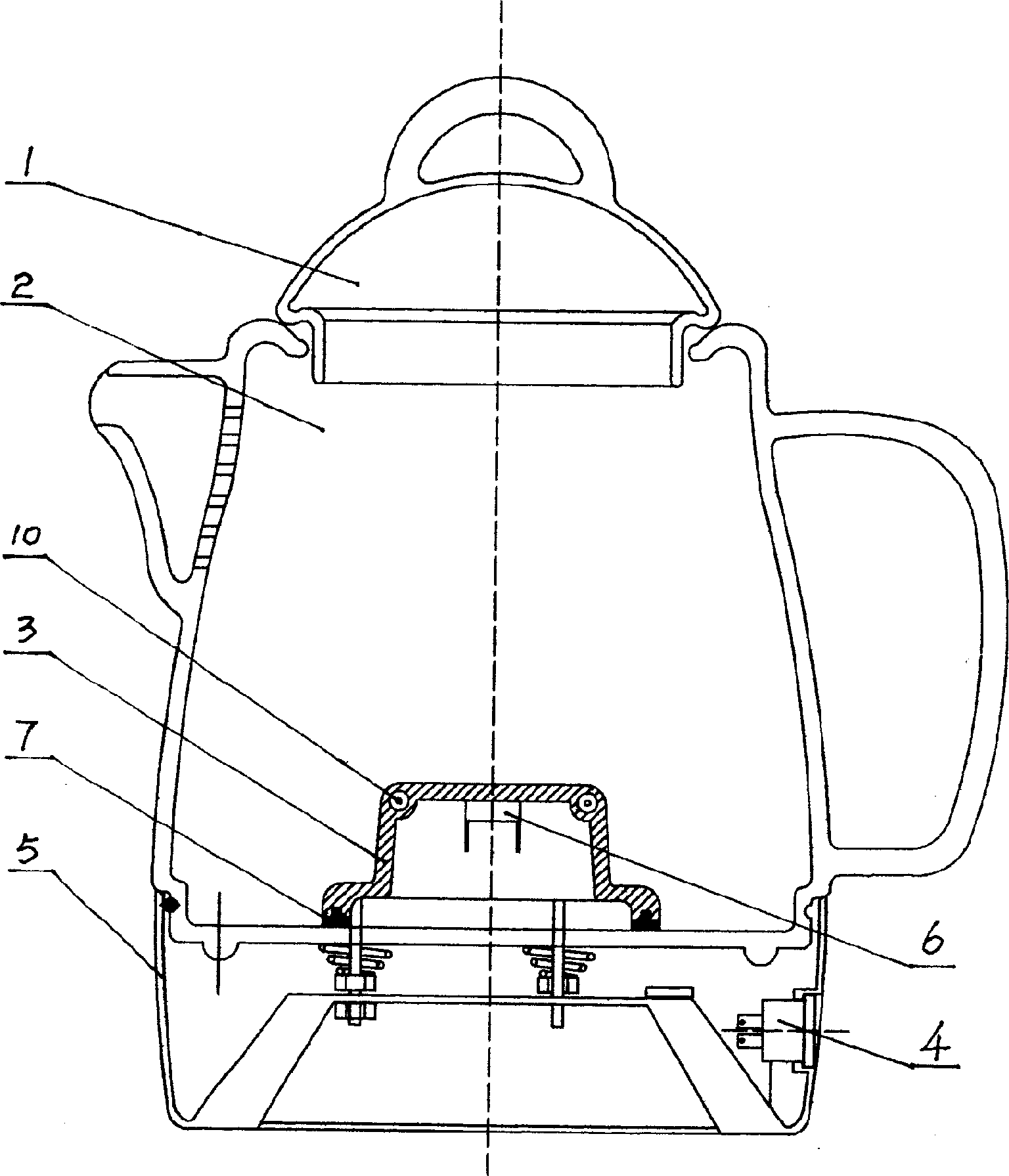

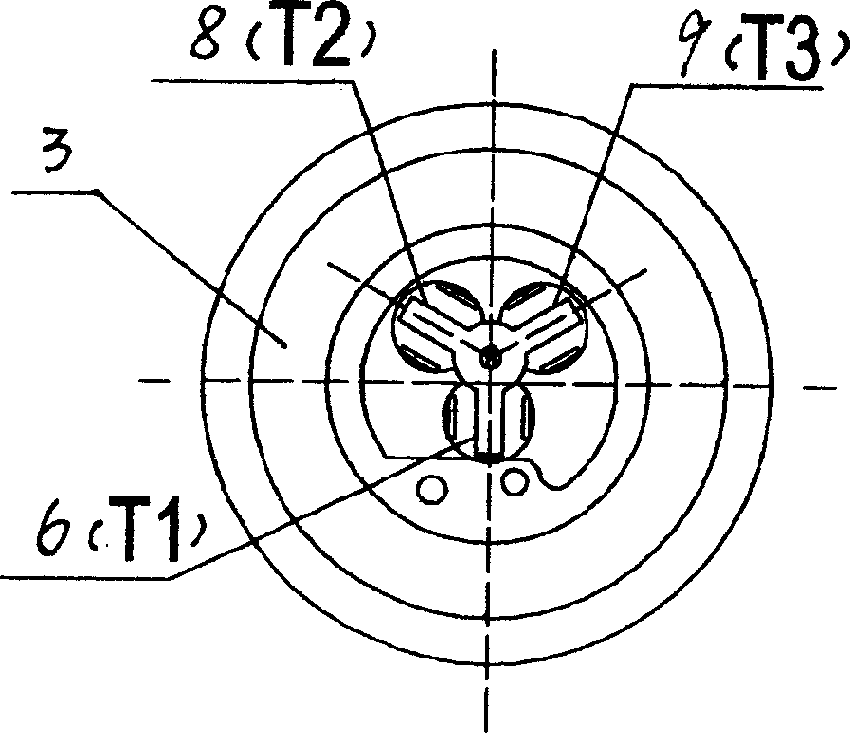

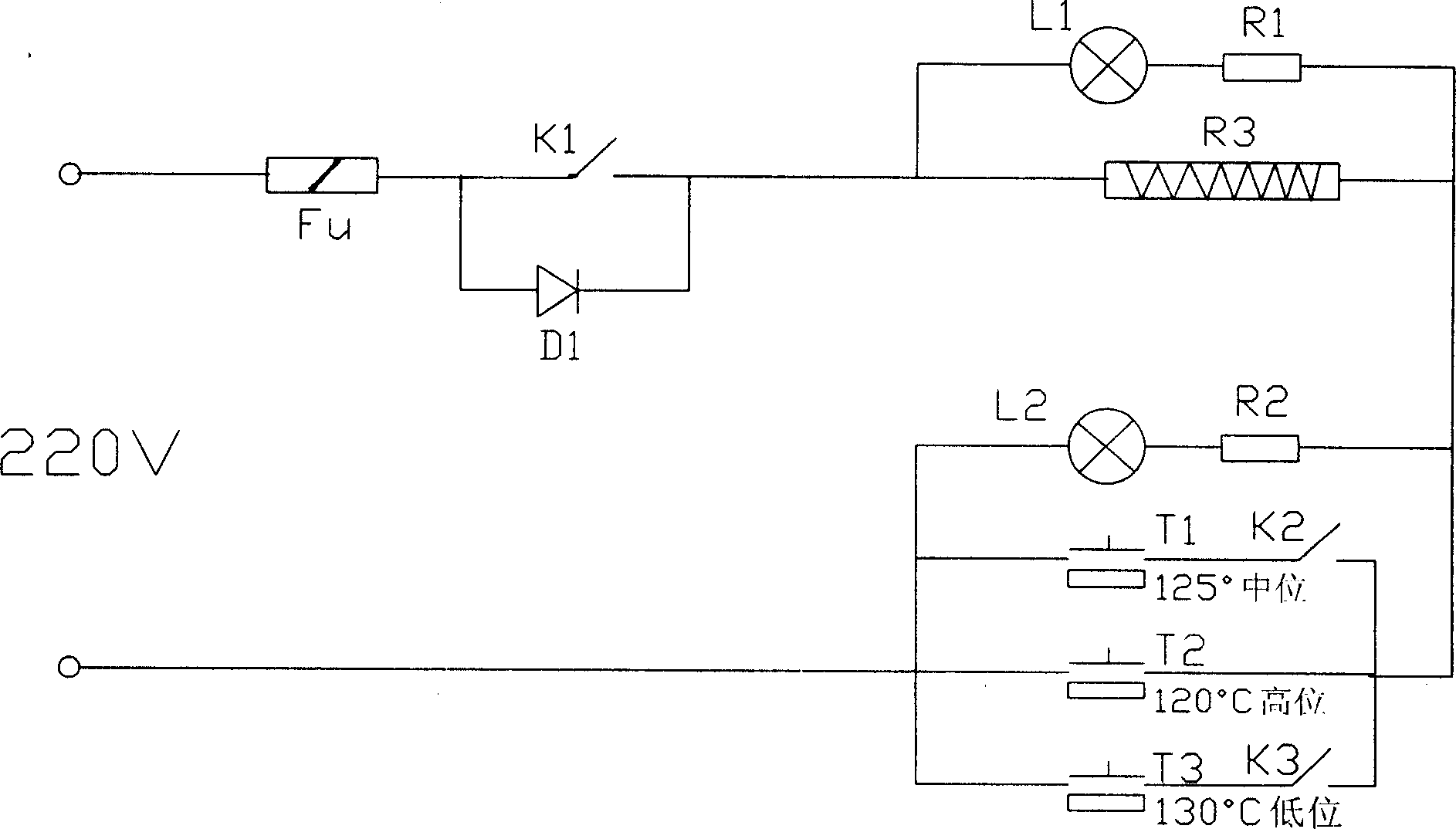

[0012] Embodiment one, see Figure 1-Figure 3 The structure of the electric medicine pot in this embodiment includes a ceramic pot lid 1, a ceramic pot body 2, a hollow boss-shaped heating element 3, an electric heating tube 10 packaged in the heating element 3, a base 5, and a power socket 4, which are close to the Three thermostats 6, 8, 9 on the inner wall of the boss-shaped heating element 3, and the sealing rubber ring 7 embedded between the boss-shaped heating element 3 and the bottom surface of the kettle body 2. The working circuit is essentially a series energized circuit of the electric heating tube and the thermostat. Specifically, the working circuit includes a power regulation circuit composed of a switch K1 and a diode D1 connected in parallel (open the switch K1 to make the circuit work at half power), The heating circuit composed of electric heating tube R3, indicator lamp L1 and resistor R1 connected in parallel consists of indicator lamp L2, resistor R2, ther...

Embodiment 2

[0015] Embodiment 2, on the basis of the above embodiment 1, the liquid level control circuit can be simplified, only the third temperature controller T3 is connected in series with the switch K3 and then connected in parallel with the first temperature controller T2, and the second temperature controller T2 is deleted. Device T1 and switch K2, like this, when the electric medicine pot is used, there are only two kinds of liquid level options, high and low, that is, two remaining doses of 660ml and 520ml. Of course, the thermostat can also be changed to be set to two remaining doses of 660ml and 580ml.

Embodiment 3

[0016] Embodiment 3, on the basis of the above embodiment 1, the number of liquid level control units in the liquid level control circuit can also be increased, such as adding 3 thermostats with different operating temperatures and corresponding switches, which can be formed after parallel connection. 6 liquid level control units, so that the remaining drug volume of the electric medicine pot can be set and selected up to 6 grades. Of course, the corresponding temperature controller’s action temperature and corresponding temperature difference should be reasonably selected and arranged. It is necessary to avoid damage to the electric medicine pot due to excessively high action temperature, and to make the grading of the remaining medicine even.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com