Active yellow dye and its built brown active dye

A reactive yellow and dye technology, applied in the field of brown reactive dyeing, can solve the problems of only 30 g/L, complicated process, and insufficient lifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

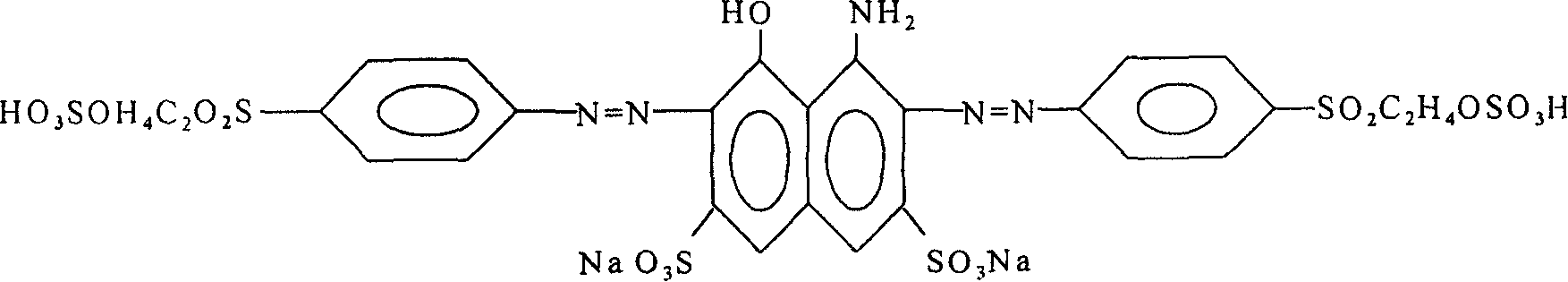

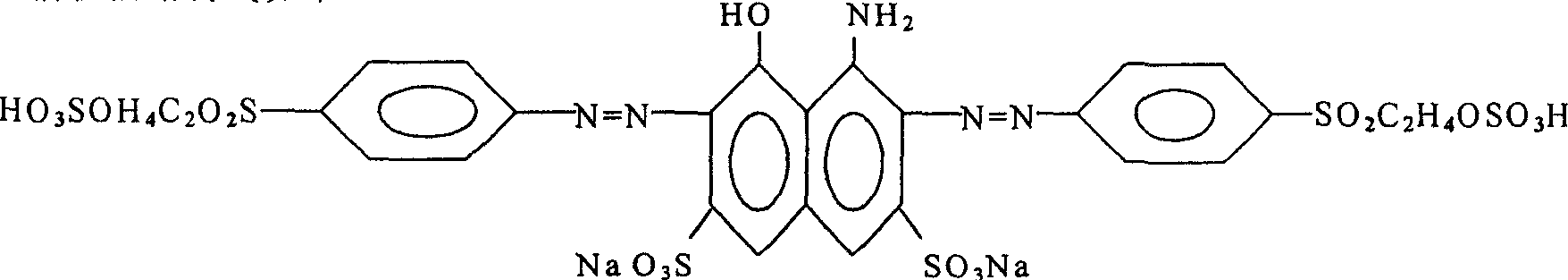

[0012] Embodiment 1: active yellow synthesis process is: sulfonated p-(β-sulfate ethyl sulfone) aniline reacts with hydrochloric acid and sodium nitrite at 0-10°C to generate diazonium salt, diazonium salt and 2.4-diaminobenzenesulfonic acid Sodium is used for acidic coupling, and the coupled product is then reacted with p-(β-sulfate ethyl sulfone) aniline, hydrochloric acid, and sodium nitrite to form a diazonium salt. Perform alkaline coupling at 5-10°C, and the pH value of the alkaline coupling is controlled at 5- 7. It is directly spray-dried after coupling, and all materials are in equimolar ratio during the synthesis process.

Embodiment 2

[0013] Example 2: 14 parts of reactive black, 17 parts of reactive red and 69 parts of reactive yellow are used for compounding and toning to form reactive brown SCE.

Embodiment 3

[0014] Example 3: 20 parts of reactive black, 15 parts of reactive red and 65 parts of reactive yellow are used for compounding and toning to form reactive brown SCE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| soaping fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com