Method for weaving two-layer yarn-dyed jacquard fabric

A technology for textiles and yarn-dyed weaving, applied in the field of textile weaving, can solve problems such as incomplete separation, narrow product adaptability, limited patterns and colors, and layers, so as to improve production efficiency, enrich textile varieties, and meet the diversified needs of the market. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

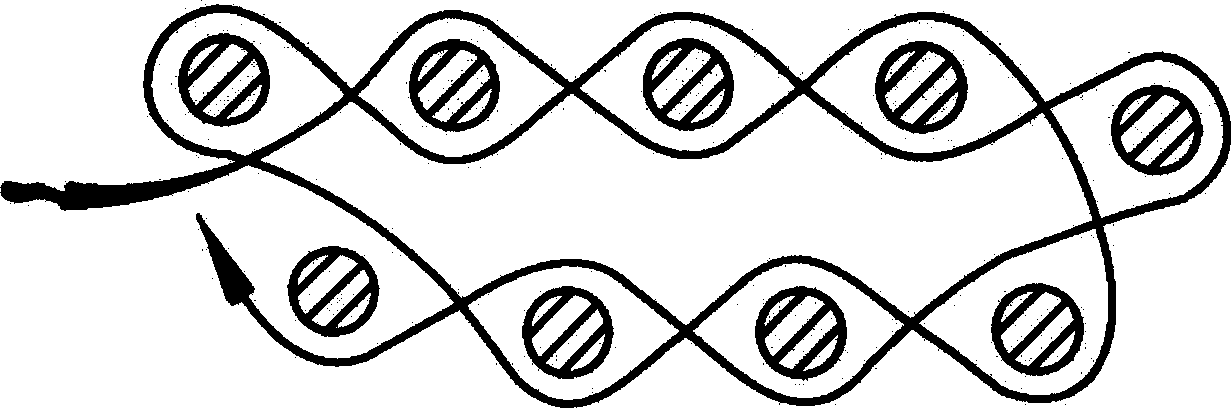

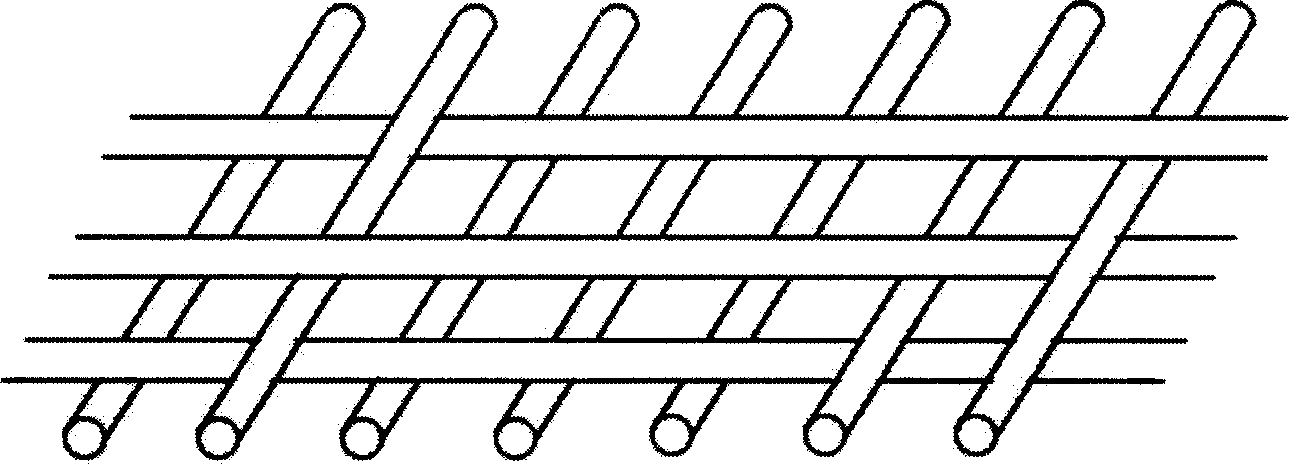

[0045] Specific embodiment 1 provides a kind of weaving method of double-layer yarn-dyed jacquard textiles, except comprising the pretreatment of aforementioned warp thread, weft thread, also comprises the following steps:

[0046] (1) The pattern design of the upper and lower fabrics refers to the pattern design according to the market demand and the color, shape, and layer that can be expressed by the double-layer jacquard technology. The patterns of the upper and lower fabrics can be the same or different.

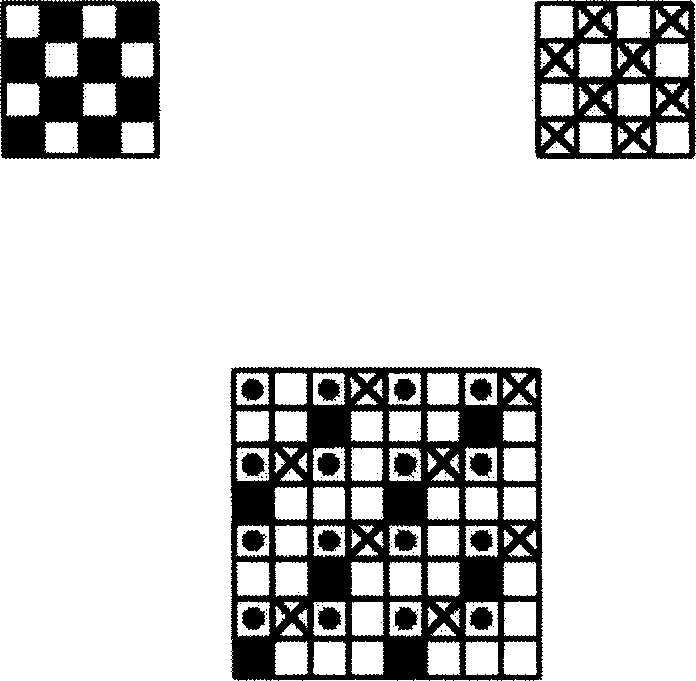

[0047] (2) The weave design of the fabric, respectively including the weave design of the upper fabric, color separation, and laying series organization structure, and the use of computer-aided design system to make the jacquard pattern file of the upper fabric; and the weave design, color separation, and laying series of the lower fabric Organize and use the computer-aided design system to make the lower fabric jacquard pattern file;

[0048] Using the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com