Internal conmbustion engine valve different lifting device and method thereof

A technology of different lifts and internal combustion engines, which is applied in the direction of valve devices, valve driving devices, mechanical equipment, etc., can solve problems such as poor flow capacity, and achieve the effect of improving internal combustion engine performance, combustion speed and fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

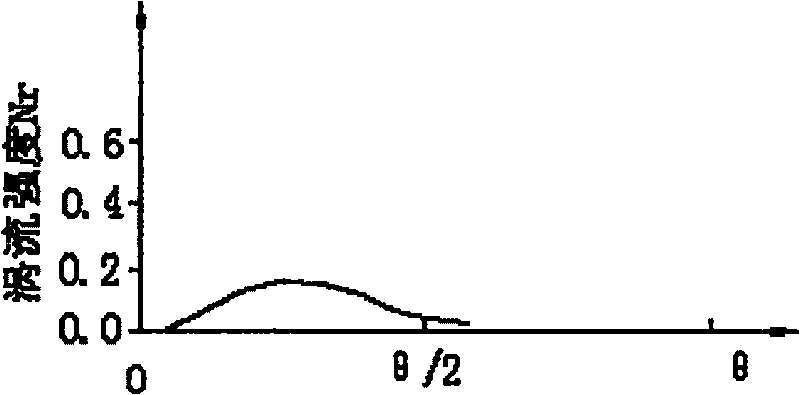

[0052] As shown in Figure 1(A), it includes a symmetrical profile cam and an asymmetrical profile cam or two asymmetrical profile cams. The maximum lift heights of the symmetrical profile cam and the asymmetric profile cam are the same, and are set on the cam The maximum lift points on the axial projection of the group of cams on the shaft coincide; the two intake valves are pushed by the two intake cams on the camshaft, the opening lift is different, and the closing lift is the same; the valve opening process There is a lift difference in the medium, there is a large-scale vortex, from weak to strong and then weakened; there is no lift difference in the valve closing process, but due to the vortex inertia at the beginning of the closing, the large-scale vortex disappears after a short period of time, as shown in Figure 1(B) The lift effect of the first embodiment is shown.

Embodiment 2

[0054] As shown in Figure 2(A), it includes a symmetrical profile cam and an asymmetrical profile cam or two asymmetrical profile cams. The maximum lift heights of the symmetrical profile cam and the asymmetric profile cam are the same, and are set on the cam The maximum lift points on the axial projection of the group of cams on the shaft coincide; the two intake valves are pushed by the two intake cams on the camshaft, the opening lift is the same, and the closing lift is different; when the valves are opened During the process, there is no lift difference and no large-scale vortex. During valve closing, there is a lift difference and large-scale vortices are generated, from weak to strong and then weakened to disappear. Figure 2(B) shows the second embodiment. The lift effect. The difference between the second embodiment and the first embodiment is that the device used in the first embodiment makes the valve opening lift different and the closing lift is the same; while the ...

Embodiment 3

[0056] As shown in Figure 3, it includes two asymmetric profile cams, the maximum lift height of the two asymmetric profile cams is consistent, and the maximum lift point on the axial projection of the group of cams set on the camshaft is In the non-coincident position, the two asymmetric contour cams are symmetrically distributed in the axial projection; the two intake valves are pushed by the two intake cams on the camshaft, and the opening lifts are different and the closing lifts are different. Different (except for the same point of lift); large-scale vortices exist during valve opening and valve closing. Due to the same lift point in the intermediate process and the influence of vortex inertia, a short period of time after the beginning of the valve closing process The large-scale vortex will gradually disappear, and then due to the increase of the lift difference, the large-scale vortex will appear again. Because the magnitude of the vortex intensity of the two intake val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com