High-voltage power supply of electrostatic cooker hood

The technology of a lampblack purifier and a high-voltage power supply is applied in the field of high-voltage power supply for an electrostatic lampblack purifier, which can solve the problem that the functional requirements of the electric field generator cannot be fully met, and achieves a device with enhanced excitation and adsorption functions, small size, and convenient impedance matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

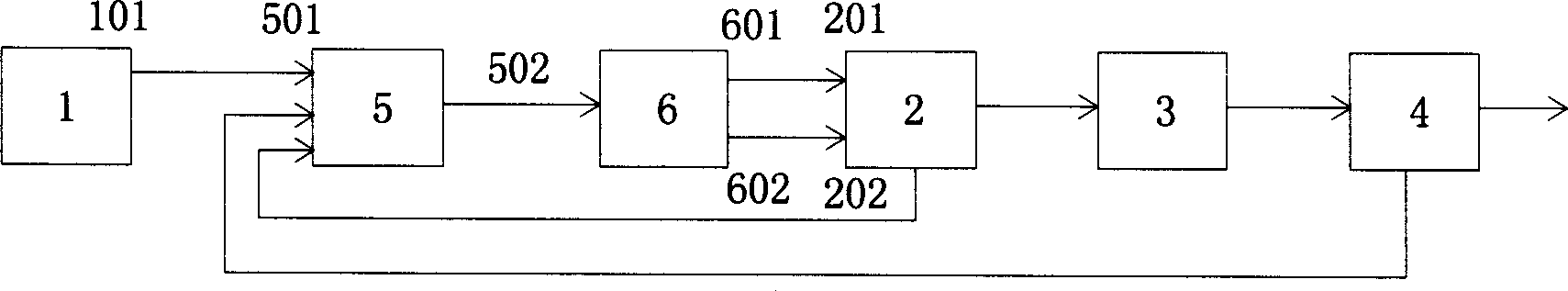

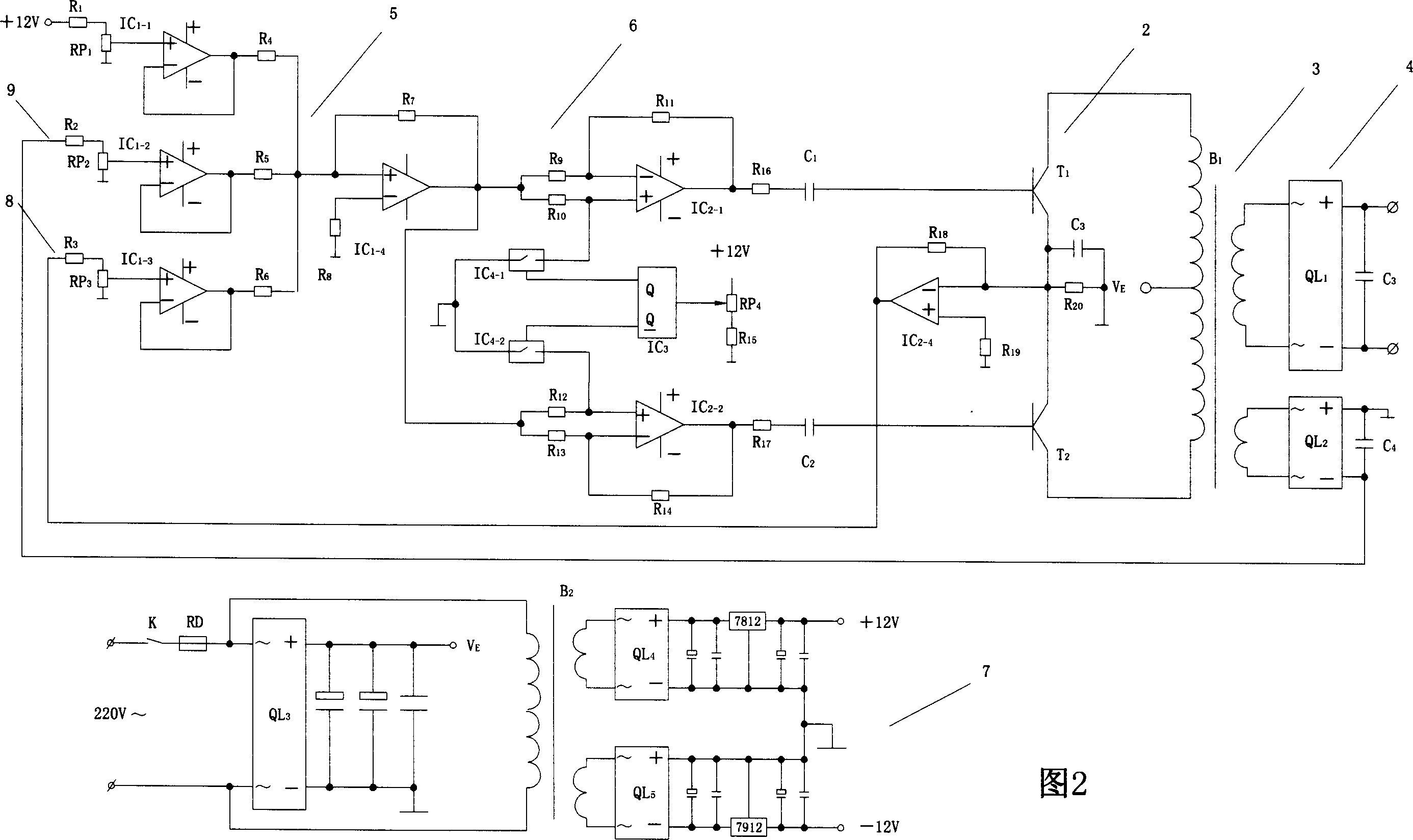

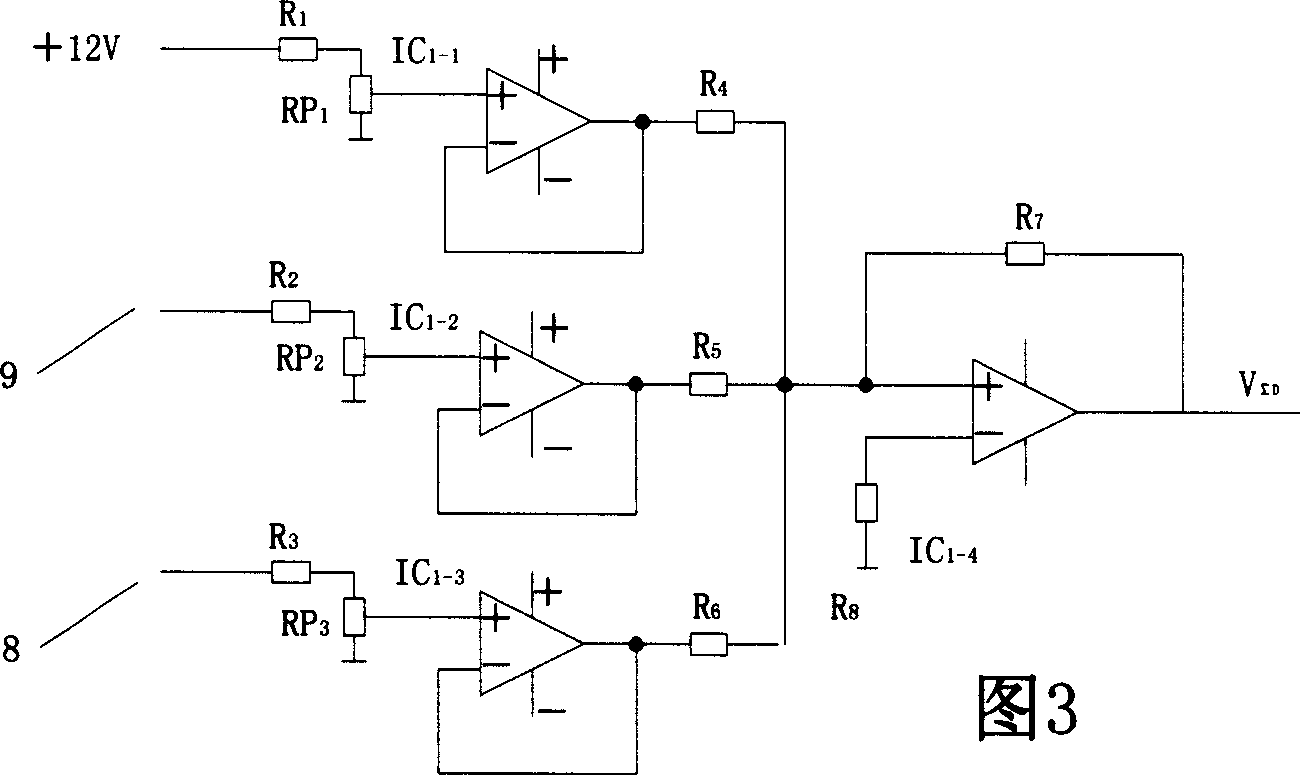

[0022] Such as figure 1 As shown in Figure 2, a high-voltage power supply for an electrostatic oil fume purifier includes a power supply circuit 7, an input rectifier circuit 1, a power amplifier circuit 2, a high-voltage transformer circuit 3 and a high-voltage output rectifier circuit 4, and the input rectifier circuit 1 and the power amplifying circuit 2 also have an amplitude modulation circuit 5 and a frequency modulation circuit 6, the setting signal input terminal 501 of the amplitude modulation circuit 5 is connected to the output terminal 101 of the input rectifier circuit 1, the signal output terminal 502 of the amplitude modulation circuit 5 is connected to the frequency modulation circuit The two input terminals 601 and 602 of the circuit 6 are connected, and the two output terminals 603 and 604 of the frequency modulation circuit 6 are respectively connected to the two input terminals 201 and 202 of the power amplifier circuit 2 .

[0023] Described amplitude modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com