Piezoelectric acoustic sensor

An acoustic sensor and sensor technology, applied in instruments, electrical devices, electromagnetic means, etc., can solve the problem that sensors are susceptible to noise and vibration sources, require high installation accuracy, and vibration signal measurement is susceptible to noise signals. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

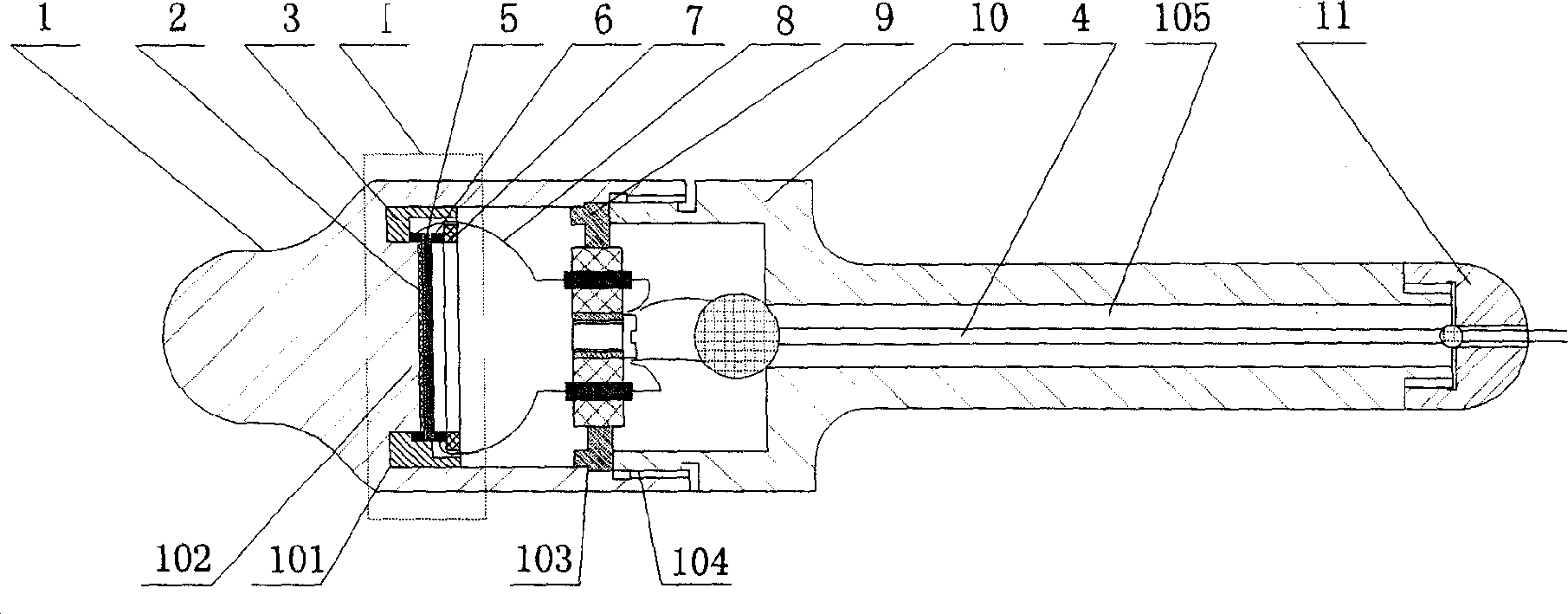

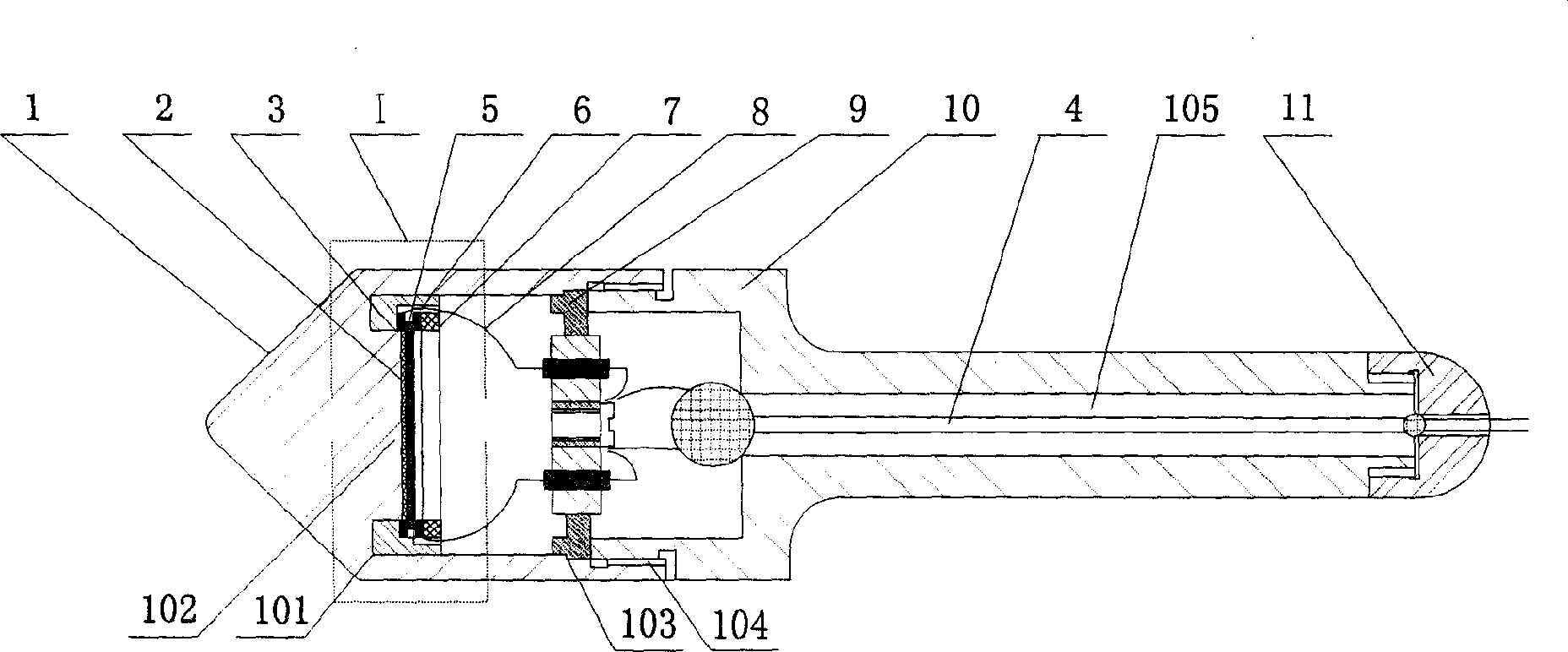

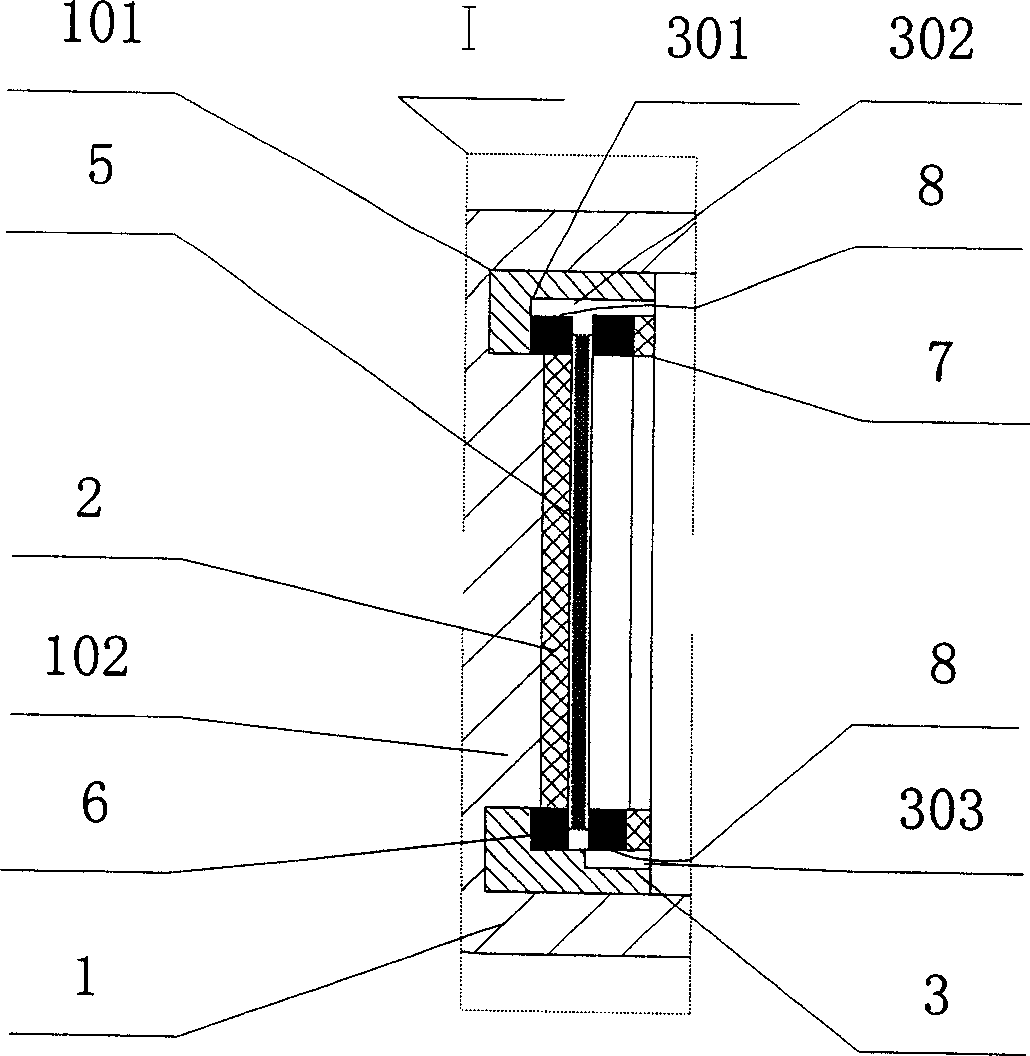

[0024] Piezoelectric acoustic sensor provided by the invention: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , including pickup probe 1, insulating glue 2, insulating seat 3, sensor output line 4, piezoelectric element 5, base electrode 6, insulating seat pressure plate 7, electrode lead wire 8, wire fixing plate 9, hand-held rod 10, sealing cap 11 and other components, the pickup probe 1 picks up the sound signal inside the operating equipment by contacting the outside of the equipment to be tested, and the insulating seat 3 and the insulating seat pressing plate 7 sandwich the piezoelectric element 5 with the base electrode 6 bonded on both sides and make the piezoelectric element 5 The electric element 5 and the base electrode 6 are insulated from the pickup probe 1, the piezoelectric element 5 and the base electrode 6 are bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com