Light-beam offset mechanic apparatus with double light wedges

A beam deflection and mechanical device technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high feed accuracy and dynamic performance requirements of stepping motors, bulky devices, and non-compact structures, and achieve the overall shape Beautiful and compact, smooth and flexible movement, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

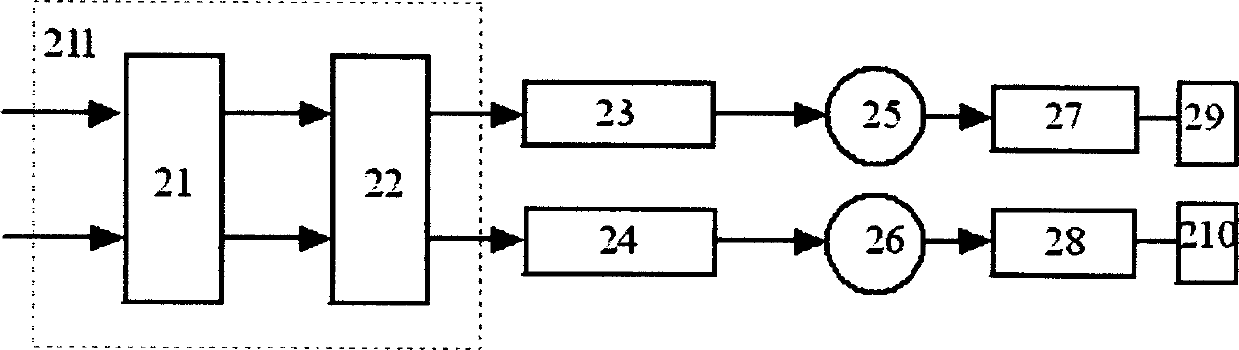

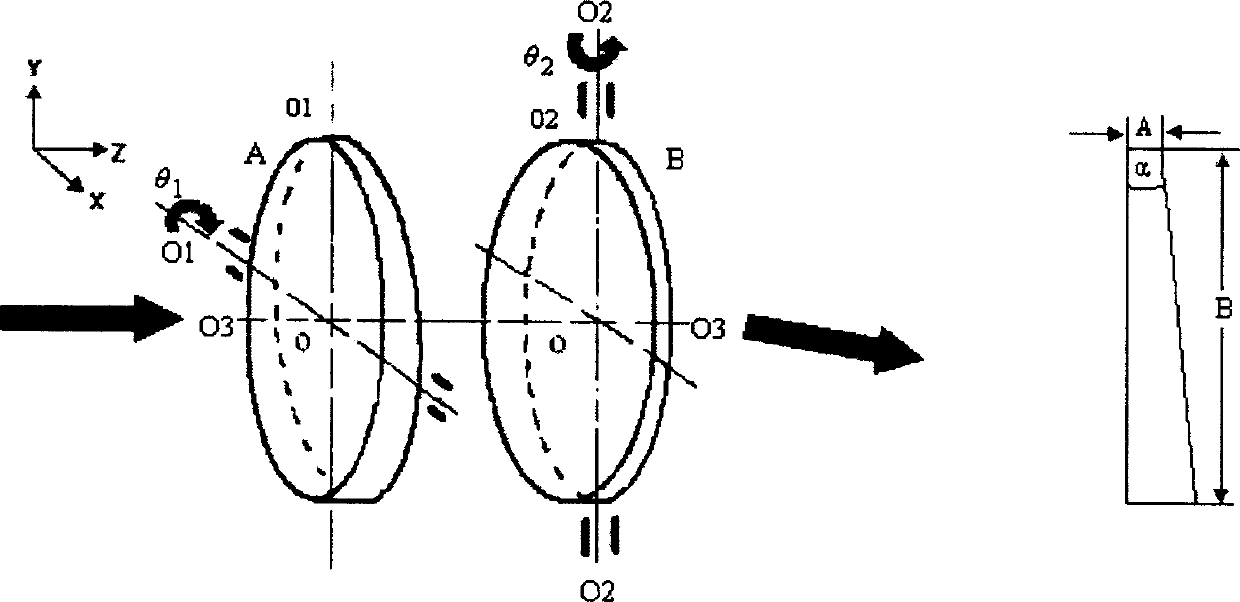

[0029] see first Figure 4 ~ Figure 6 shown. The double optical wedge beam deflection mechanical device of the present invention comprises a first optical wedge, a second optical wedge, a first linear stepper motor, a second linear stepper motor, a first angle encoder, a second optical wedge which rotate around orthogonal axes respectively Two angle encoders and one base, its features are:

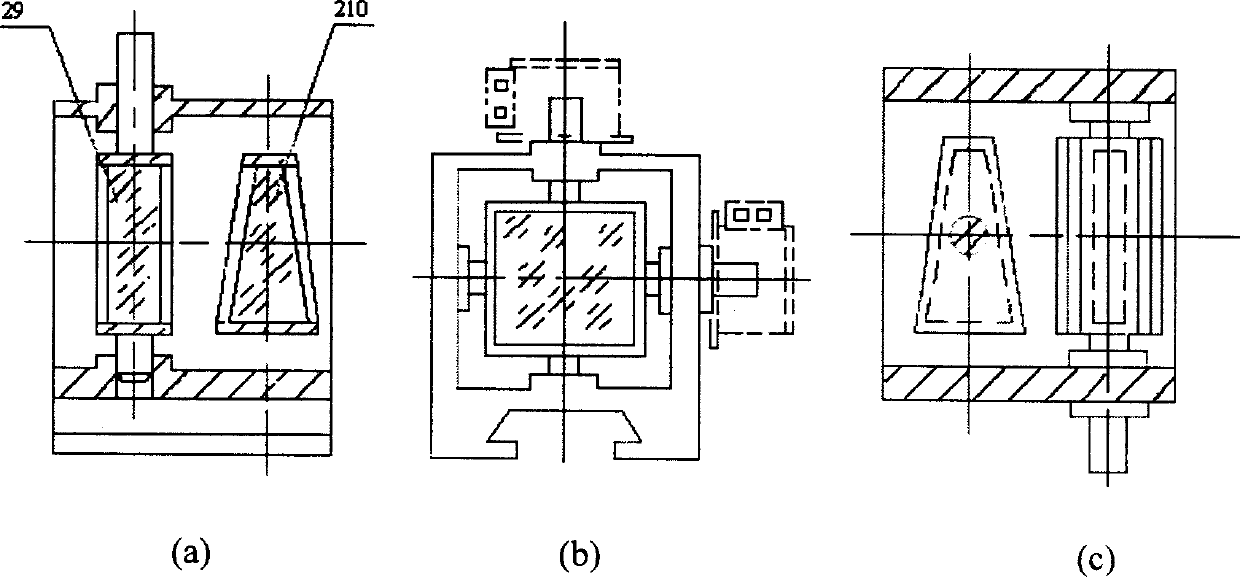

[0030] The first optical wedge and frame assembly 2 and the second optical wedge and frame assembly 3 are centrally arranged in the base 1:

[0031] The composition of the first optical wedge and the mirror frame assembly 2: refer to Figure 7 , the first optical wedge 21 is glued into the inner lens frame 22, the wedge surface of the first optical wedge 21 is supported by the wedge washer 24, and contacts the inner lens frame 22 through the O-ring 27, and the inner lens frame 22 is placed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com