Composite tool insert

一种衬片、刀具的技术,应用在刀具衬片领域,能够解决操作耗时、花掉时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

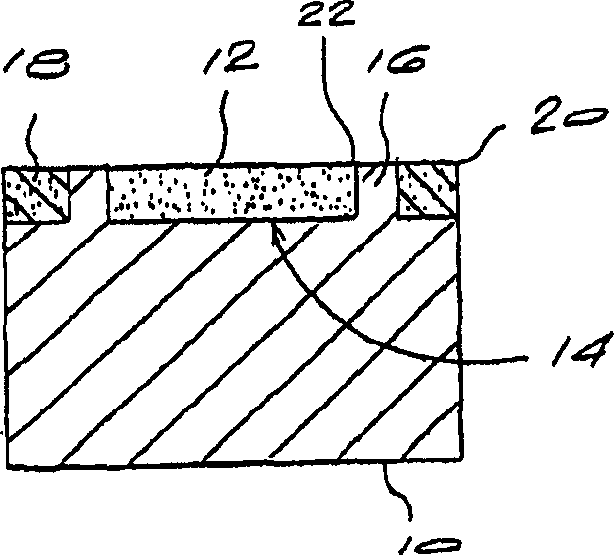

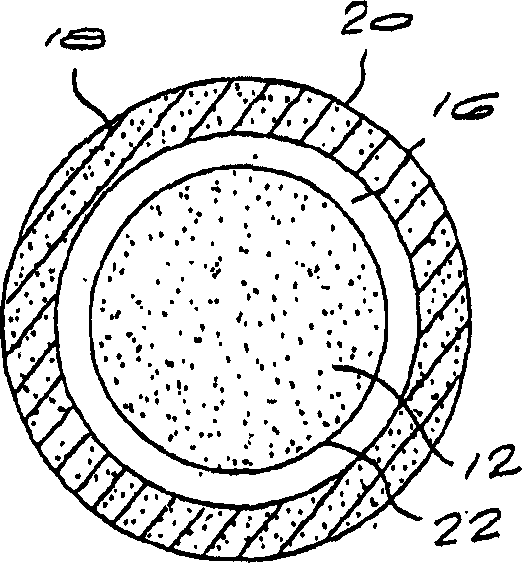

[0012] Refer to the attached figure 1 and figure 2 , the embodiment of the specific tool lining of the present invention is shown in the figure. The tool lining comprises: a tungsten carbide base layer 10; a PCD layer 12 disposed in a recess 14 and surrounded by a tungsten carbide annular portion or ring 16 extending laterally from a support surface 17; and a surrounding ring 16 protective layer or protective ring 18.

[0013] The guard ring 18 may be made of a different grade of tungsten carbide than the tungsten carbide base layer 10, or may be made of tool steel or other suitable materials. The choice of material depends on the substance or substrate to be milled, drilled or cut prior to exposing the PCD layer 12 . The guard ring 18 can be formed in situ, or as a separate ring-shaped component that fits onto the knife lining. The guard ring 18 may be bonded by brazing, press-fitting, burn-in or other convenient means to the tool lining which has been machined to receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com