Capillary electrophoretic chip with extraining sampling and its using method

A capillary electrophoresis and sample injection technology, applied in the field of chemical and biological analysis and detection, can solve the problems of affecting separation efficiency, sacrificing detection sensitivity, affecting analysis speed, etc., to improve separation efficiency, ensure detection sensitivity, and avoid background noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

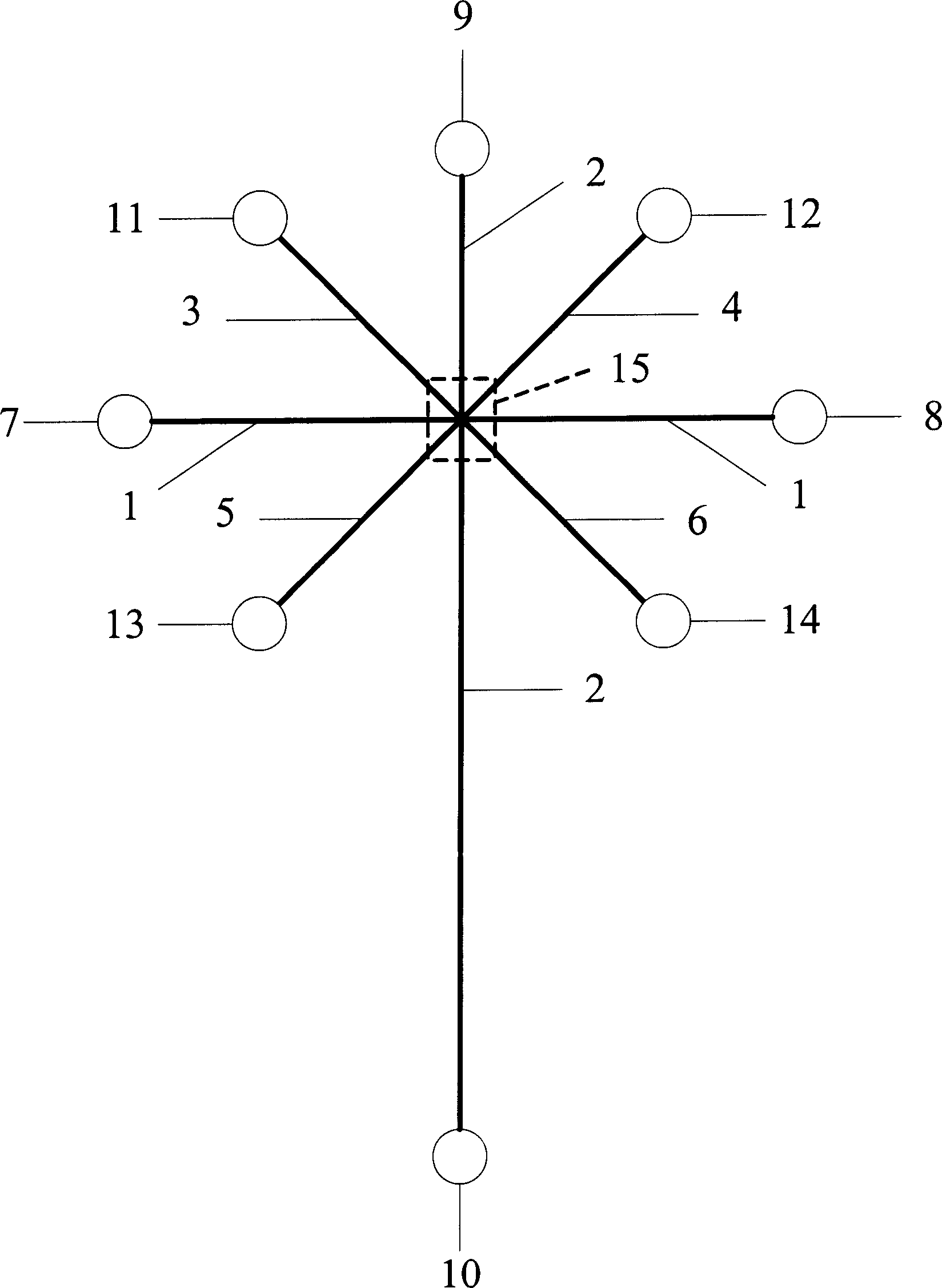

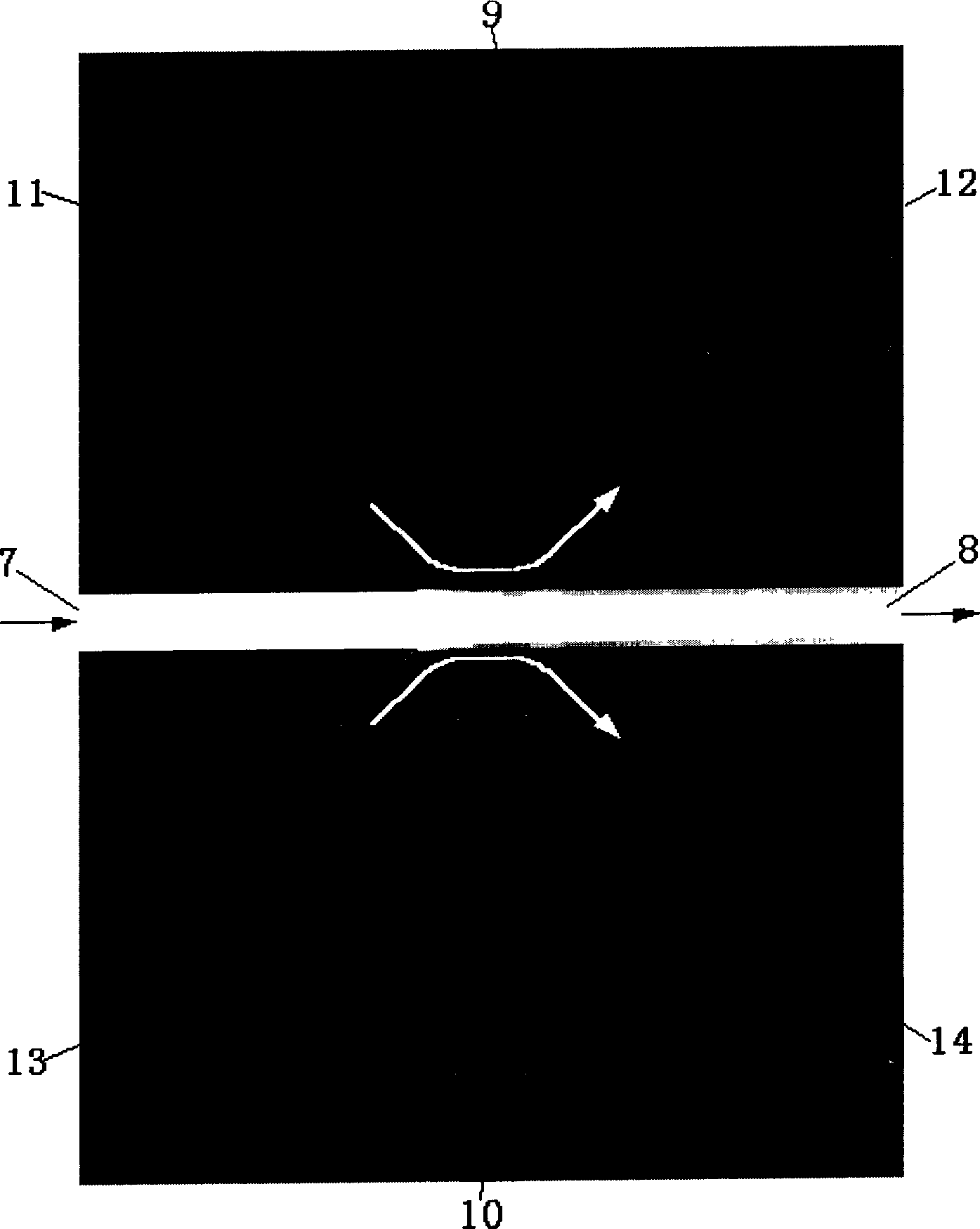

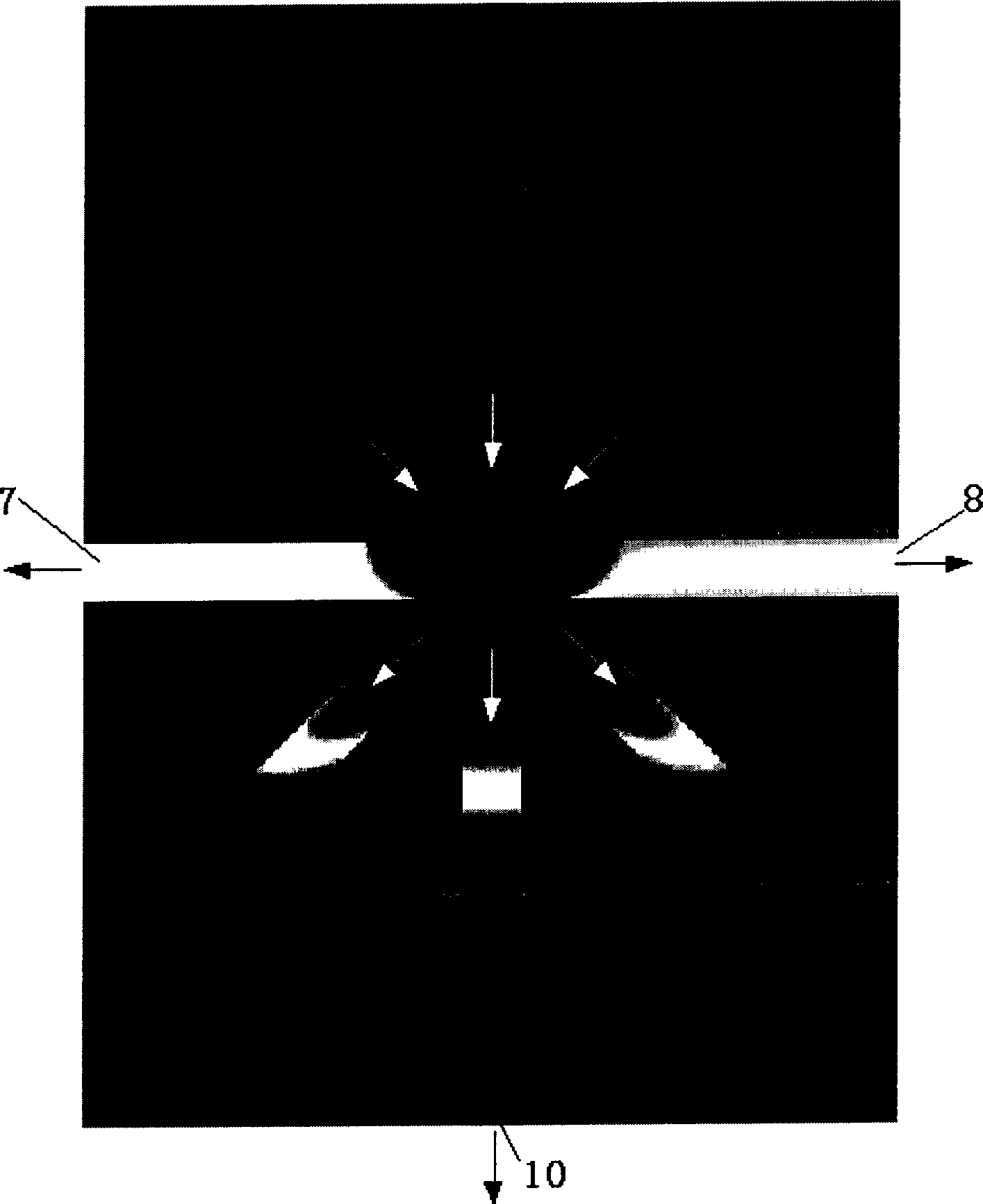

[0017] Such as figure 1 As shown, the capillary electrophoresis chip of the present invention with entrained flow sampling and its use method include a sampling channel 1 and a separation channel 2, the sampling channel 1 and the separation channel 2 are in vertical "cross" communication, and the sampling channel 1 The two ends are respectively connected with the sample liquid pool 7 and the waste liquid pool 8; the two ends of the separation channel 2 are respectively connected with the buffer pool 9 and the waste liquid pool 10, and also include four auxiliary entrainment channels, which are respectively the first auxiliary channel 3, the second auxiliary channel Two auxiliary channels 4, the third auxiliary channel 5 and the fourth auxiliary channel 6, the auxiliary entrainment channels are respectively located in the four regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com