Aluminum nitride powder, method for producing the same and use thereof

A manufacturing method and aluminum nitride technology are applied in the fields of aluminum nitride powder and its manufacture and use to achieve the effect of reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

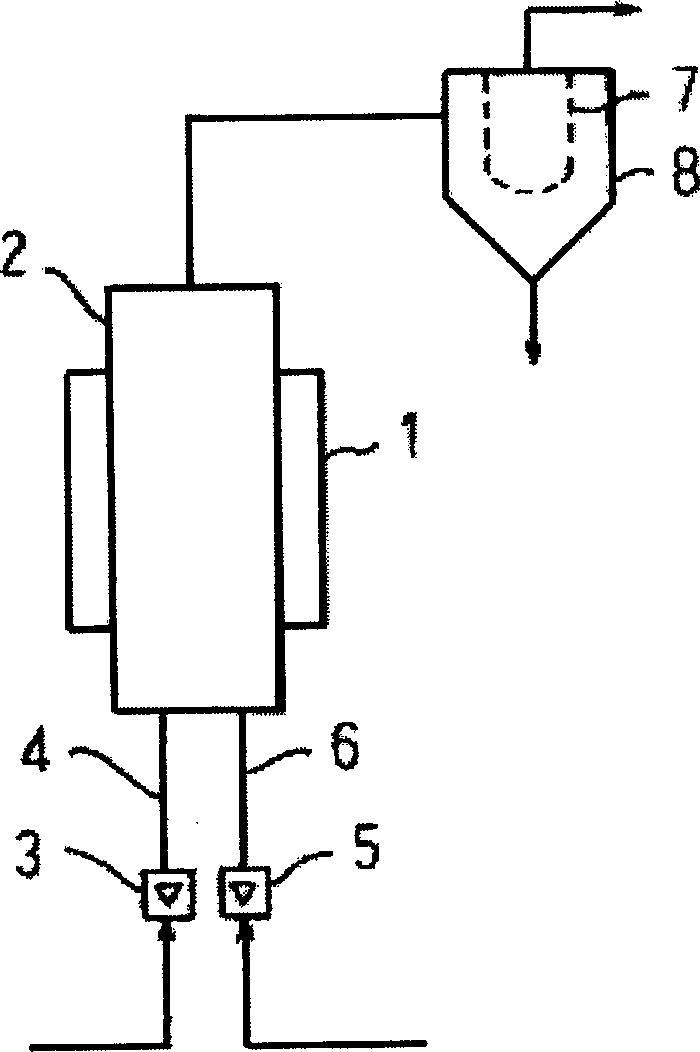

[0073] use as figure 1 In the shown gas phase reaction apparatus, the reactor 2 is heated by the heating belt 1 and kept at 500° C., and ammonia is introduced through the supply pipe 4 while adjusting the flow rate regulator 3 at the lower part of the reactor 2 . At the same time, triethylaluminum accompanied by nitrogen gas was introduced through the supply pipe 6 while being adjusted by the flow meter 5 . The flow rate is adjusted by the flow regulators 3 and 5 so that the residence time of the reaction gas in the heating area (reaction area) is 2 seconds. Also, the molar ratio of ammonia / triethylaluminum was 20.

[0074] The aluminum nitride powder produced in the reaction area is taken out together with the unreacted gas through the upper part of the reactor 2, separated from the gas by the filter 7, and collected in the collector 8. The collected aluminum nitride powder was put into a stone grinding tube, and heat treatment was carried out at 1300° C. for 3 hours in an ...

Embodiment 2

[0078] After ball milling, processing relative to 100 parts by weight of aluminum nitride, adding Y 2 o 3 3 parts by weight Y 2 o 3 Aluminum nitride powder was sintered in the same manner as in Example 1 except for the sintering aid. The density of the sintered body is 3.29g / cm 3 , is the theoretical density (add Y 2 o 3 99.4% of the corrected value) and the thermal conductivity is 110W / m·k.

Embodiment 3

[0080] Aluminum nitride powder was synthesized in the same manner as in Example 2, except that the heat treatment temperature was 1400° C., and the ground and pulverized spherical medium was 0.5 mmφ zirconia pellets. The specific surface area of the powder after heat treatment is 8.2m 2 / g, the specific surface area after crushing is 33m 2 / g, the primary particle size converted from this is 0.056 μm. In addition, the particle size of the secondary particles was 0.5 μm. Thus, the degree of aggregation was 8.9. The density of the obtained sintered body is 3.25g / cm 3 , which is 98.2% of the theoretical density. In addition, the thermal conductivity was 113 W / m·k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com