Non-contact type hydrojet grinding head in use for digital controlled polishing

A non-contact, polishing liquid technology, used in optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of difficult to control the distribution of polishing paste, difficult to control uniformity, affecting the polishing quality, etc., to avoid the workpiece on the workpiece. Local stress, uniformity guarantee, effect of improving polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

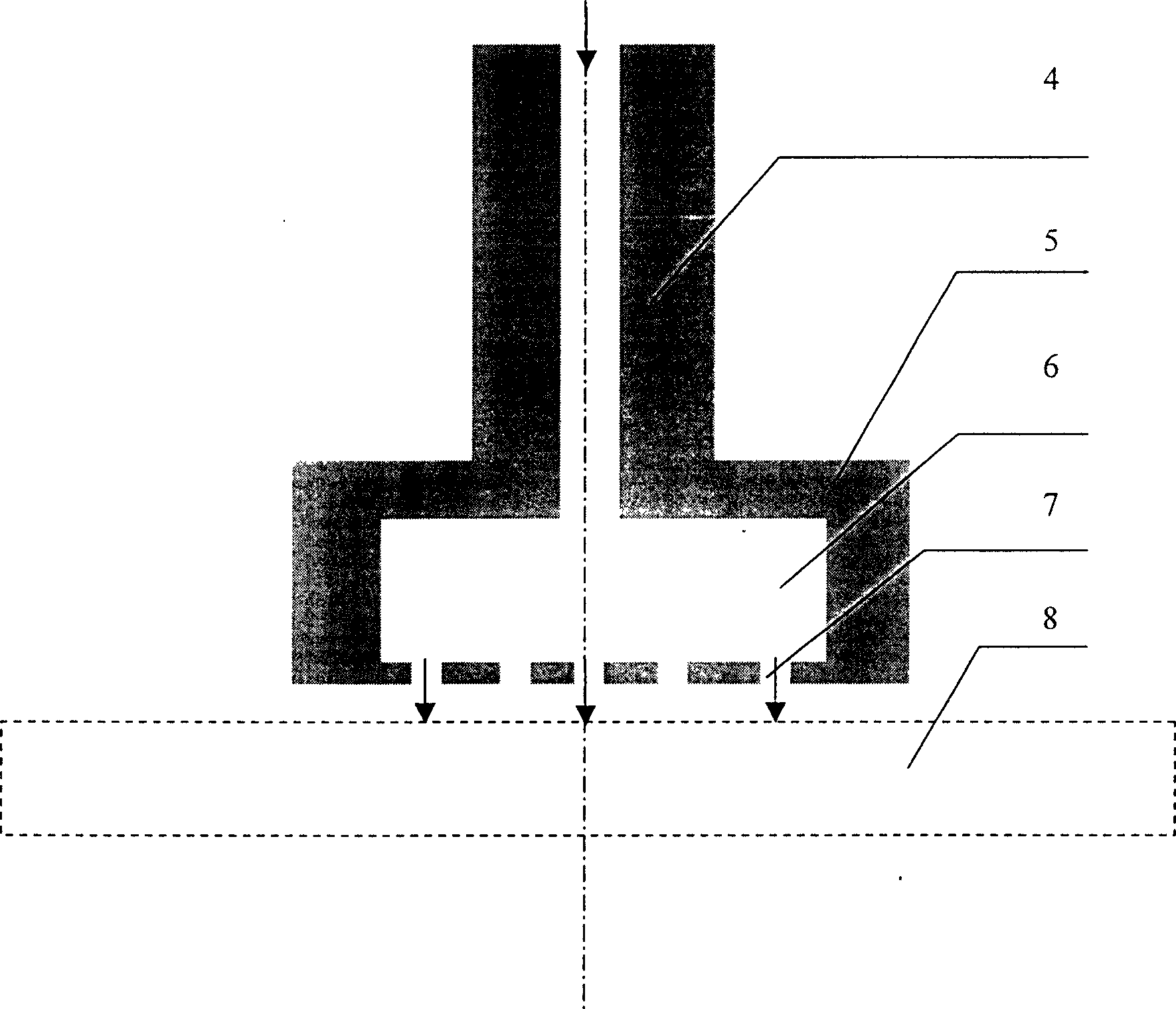

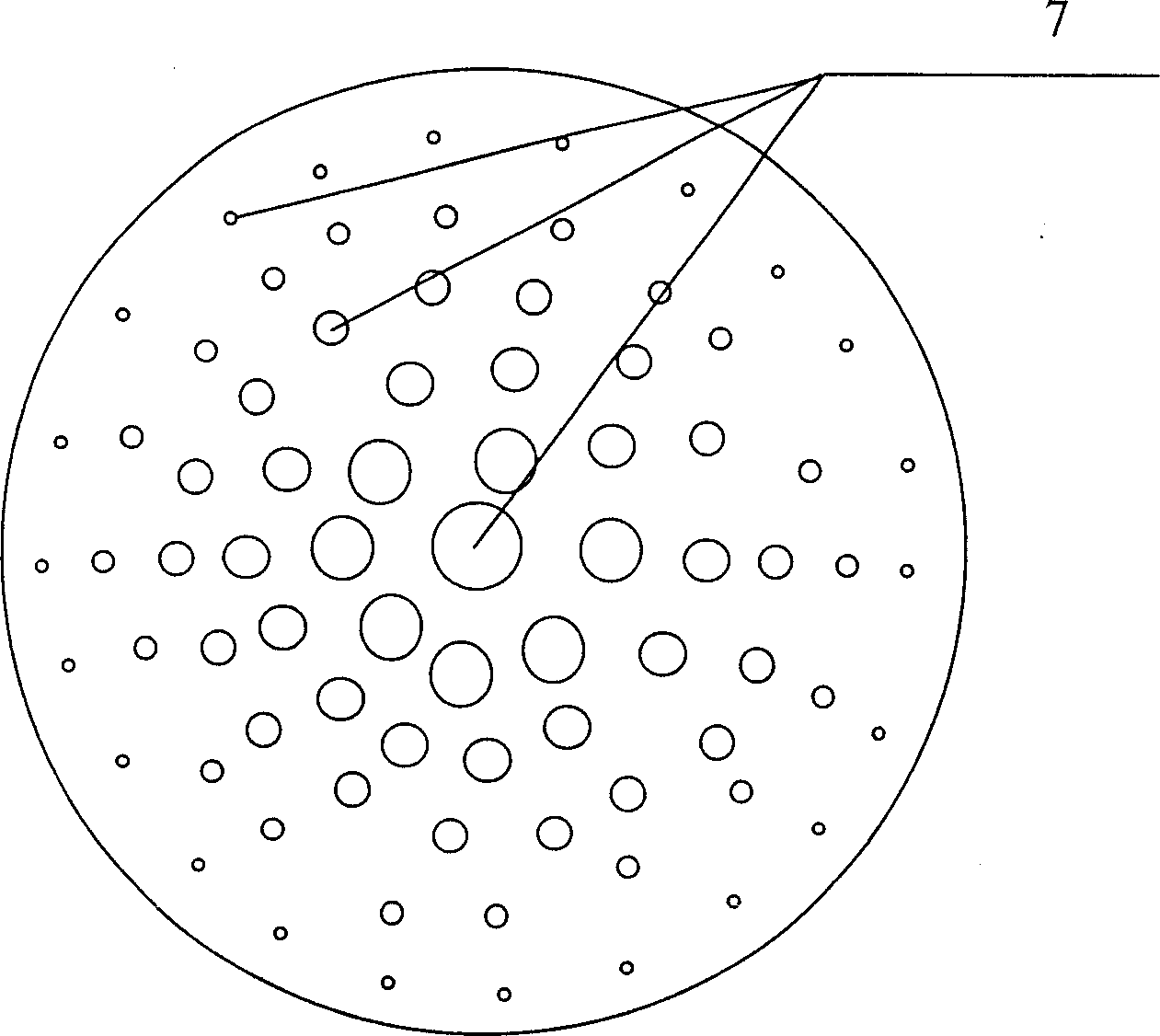

[0010] The invention according to figure 2 The structure shown is implemented, wherein the material of the hollow drive shaft 4 and the hollow grinding head 5 is stainless steel, and the two are integral hollow parts or two parts are matching hollow parts. Thread fit, the size of the grinding head is related to the size of the optical part to be processed, generally 1 / 5 of the size of the optical part to be processed, the surface shape of the workpiece surface of the grinding head is better, and the flatness is better than 1 / 10λ° , the size of the polishing fluid outlet hole 7, the largest hole is 200μ, the smallest hole is 40μ, the hole in the center of the working surface of the grinding head is the largest, the transition to the edge, the smaller the polishing fluid outlet hole, the distribution of the holes adopts concentric circles The distribution or spiral distribution is adopted, and the distance between the holes in each direction is about 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com