Self-electricity-generating laser positioning device of aperture processing machine

A technology of laser positioning and hole processing, which is used in positioning devices, metal processing mechanical parts, metal processing equipment, etc., and can solve the problems of insufficient power supply, low current, and trouble of laser transmitters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

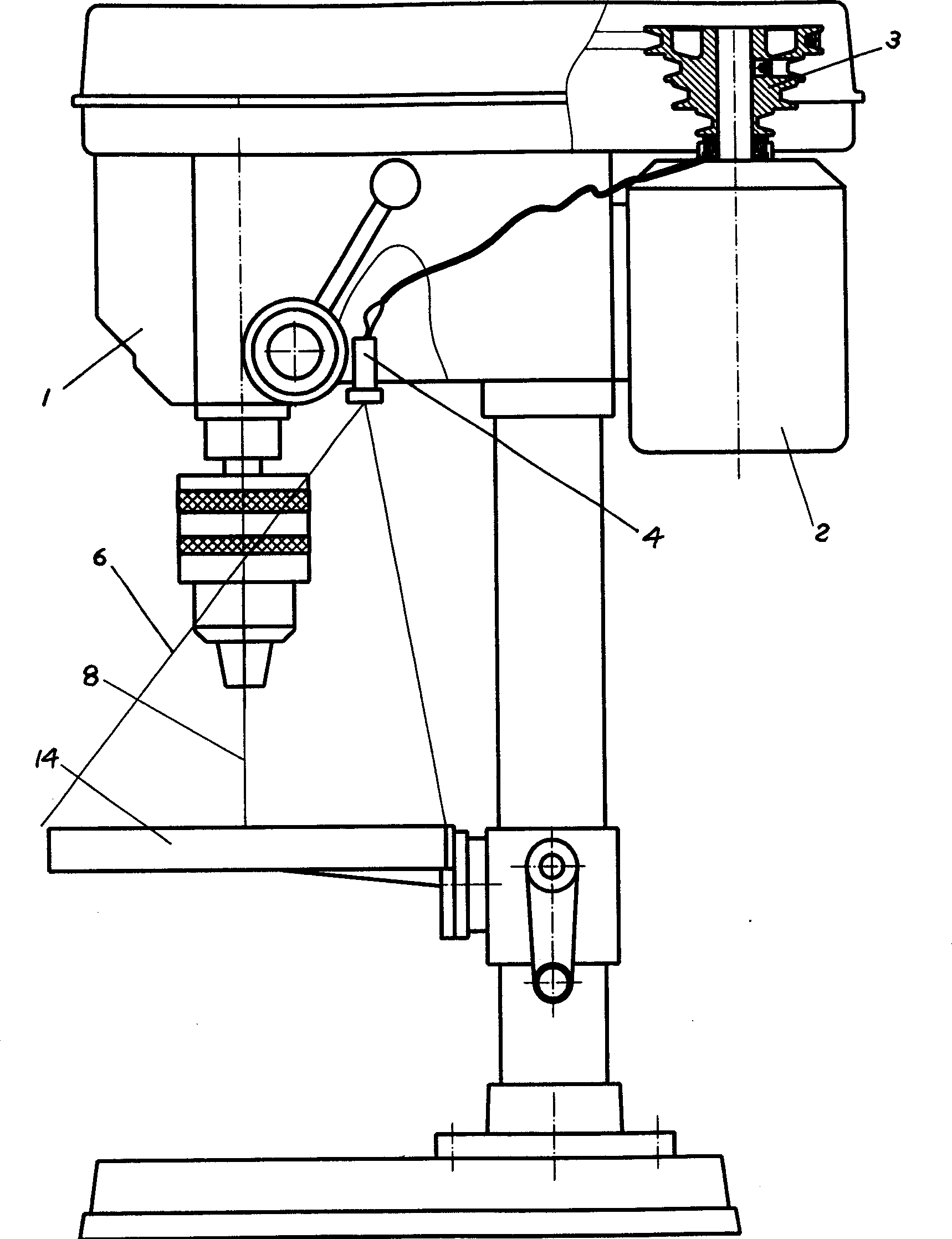

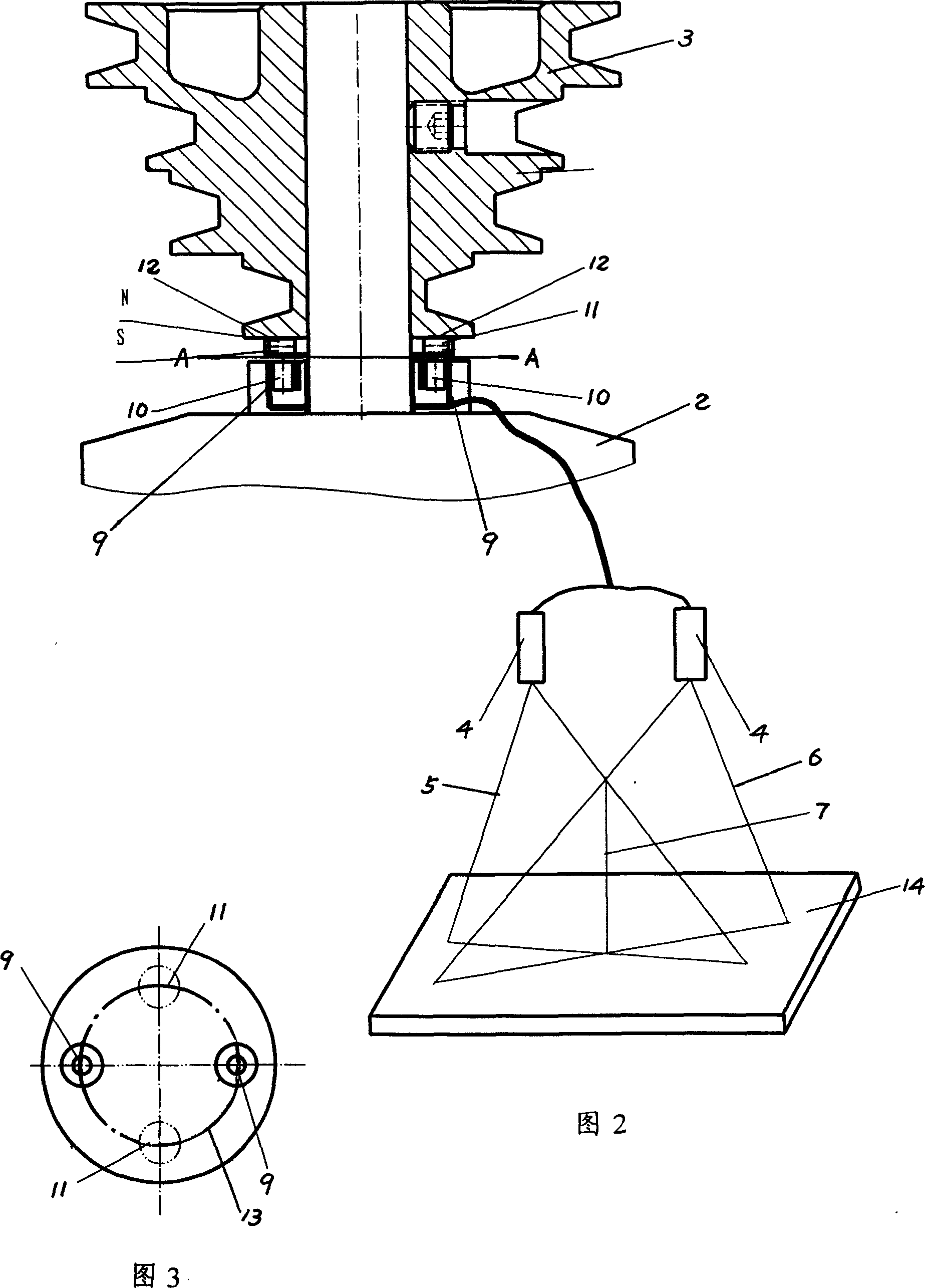

[0014] Example 1. A self-powered laser positioning device for hole processing machinery, such as figure 1 ~ As shown in Figure 3. This is a self-powered laser positioning device for bench drills.

[0015] The bench drill includes a headstock 1, a motor 2 fixed on the headstock 1, and a driving pulley 3 fixed on the shaft of the motor 2 and other components. Two laser emitters 4 are fixed under the headstock 1, and the two laser emitters 4 respectively emit plane beams 5 and 6 downward, and the intersection line 7 of the two plane beams 5 and 6 coincides with the center of the spindle 8. Two laser transmitters 4 are connected to the induction current coil for power supply. The induced current coil includes a coil 9 fixed on the end cover of the motor 2, an iron core 10 fixed in the coil 9, and a permanent magnet 11 fixed on the lower edge of the driving pulley 3. The distance between the fixed position of the coil 9 and the permanent magnet 11 and the motor axis 8 is equal. 14 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com