Double conical rotary kiln for carbon calcination

A rotary kiln and double-cone technology, applied in the field of rotary kiln, can solve problems such as the capacity limitation of the rotary kiln, and achieve the effect of avoiding the return of materials at the kiln tail and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

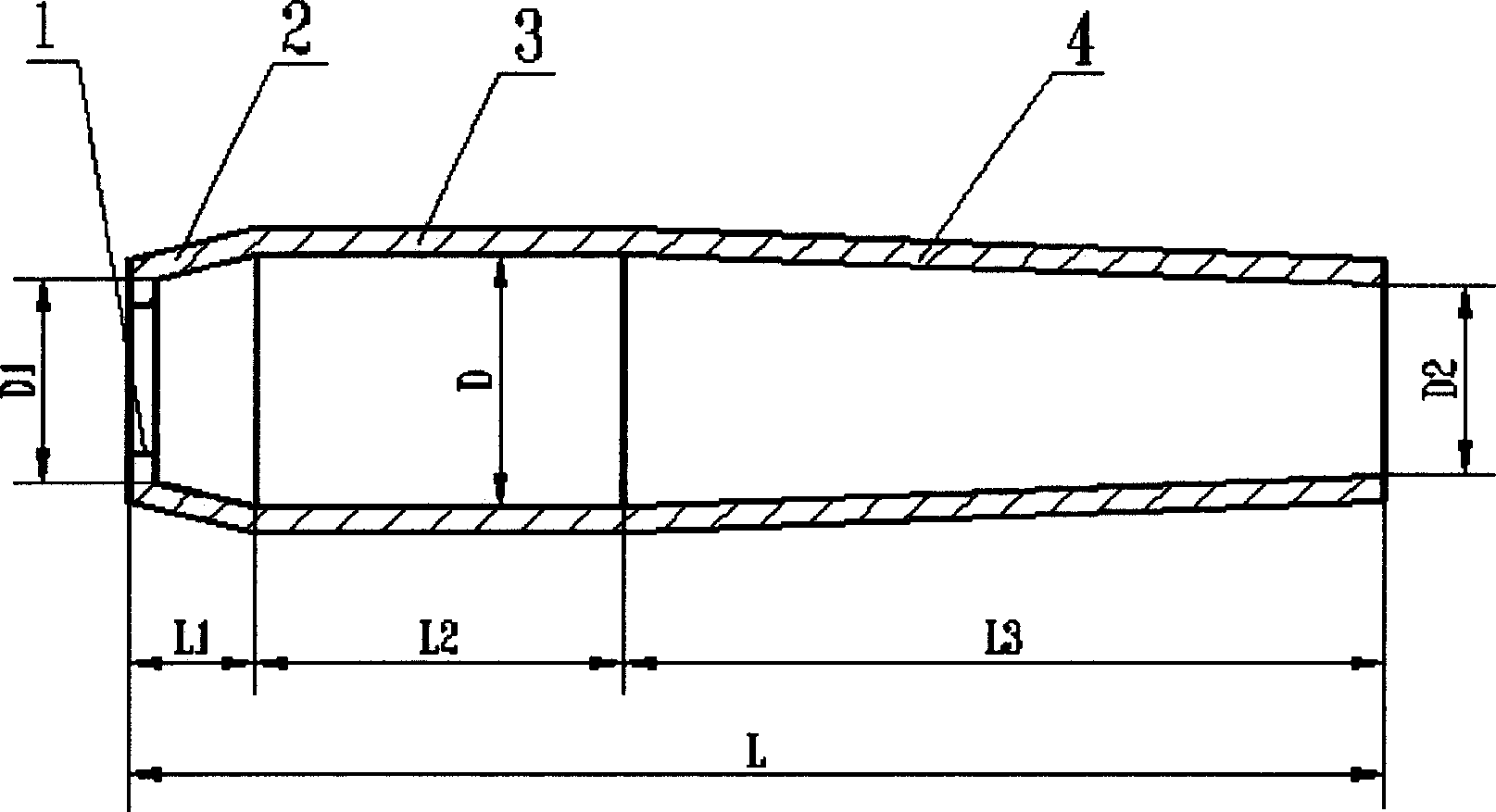

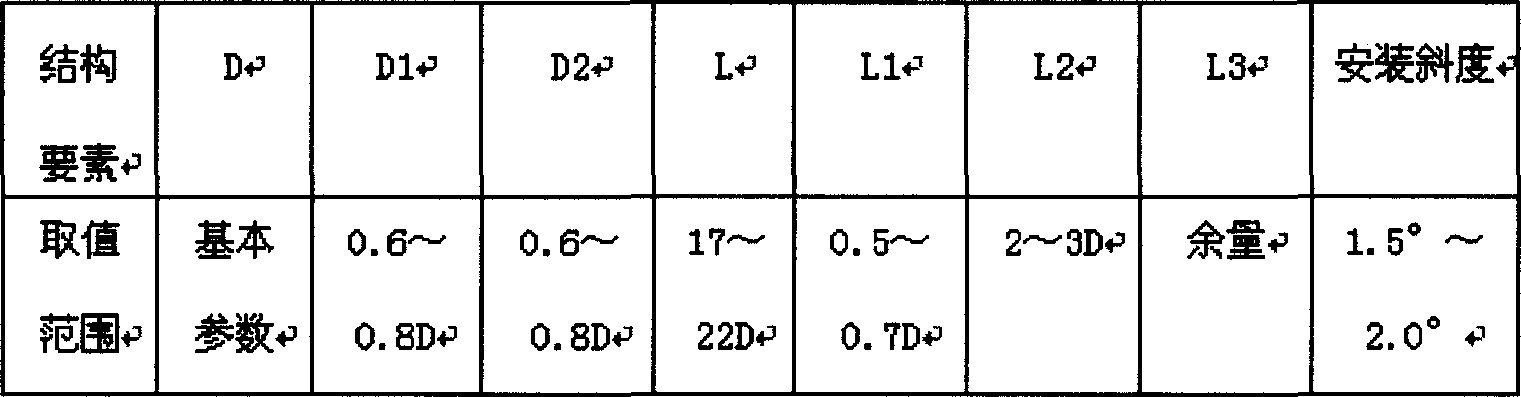

[0028] Wherein, the diameter of feed inlet 1 is 1.4m, and the thickness of rotary kiln lining is 250mm, and the inclination of the conical bottom of feed end cone 2 is calculated as (1.72+17.53)°=19.25°, The inclination of the conical bottom of the cone 4 at the discharge end is (1.72-0.45)°=1.27°.

[0029] according to figure 1 The connection relationship shown is connected, that is, the feed end cone 2 is connected with the middle straight cylinder 3, and the middle straight cylinder 3 is connected with the discharge end cone 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com