Static elimination equipment for cigarette package production and static elimination method thereof

A technology for eliminating static electricity in the production process, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as easily damaged transparent paper, poor static elimination effect, and dangerous operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

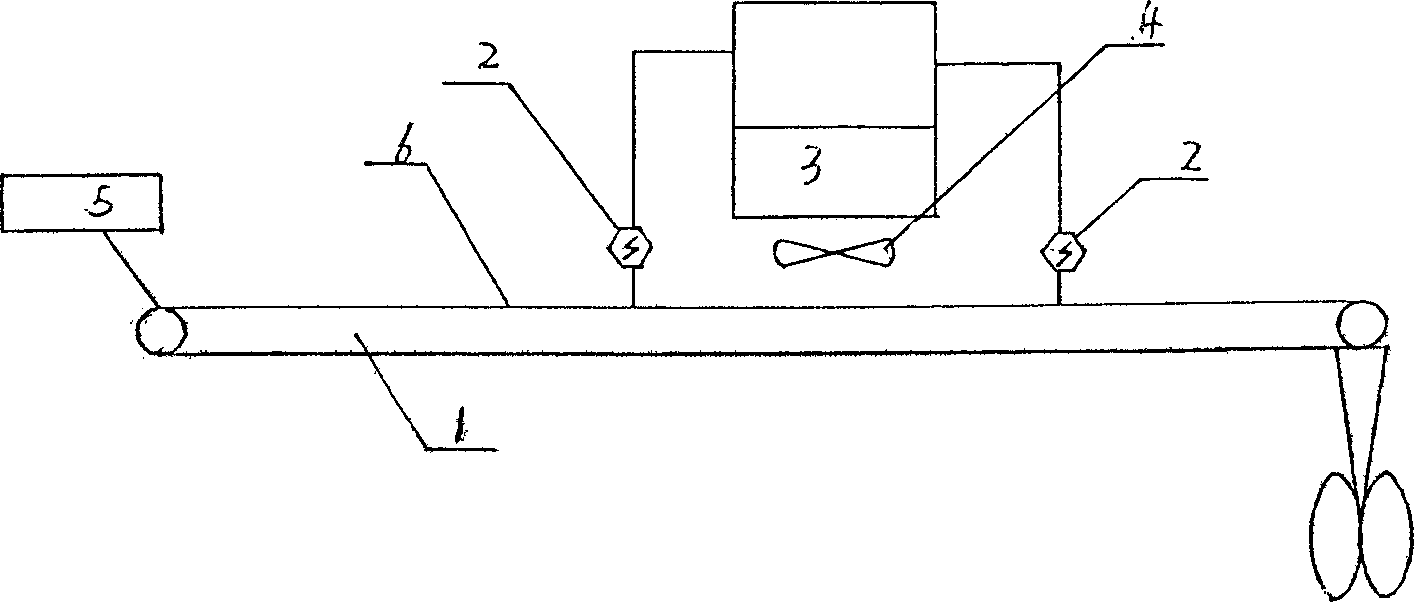

[0021] In Fig. 1, the conveyor belt 1 moves under the action of the transmission shaft 5, and the transparent paper material 6 on it moves accordingly. When it reaches the electrostatic detector I2A, the electrostatic detector will detect the electrostatic charge on the transparent paper material, and convert the polarity and intensity of the detected electrostatic charge into an electrical signal and send it to the electrostatic generator connected to it. In the control circuit of the device 3, the control circuit will control its corona discharger according to the signal to generate neutralization charges of opposite polarity, and under the action of the fan 4, the charges will be blown to the transparent paper material in the form of ion wind to make it The static electricity on the surface is neutralized, and then the static electricity detector II2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com