Film forming method, film forming device and storage medium

A film-forming method and technology of a film-forming device are applied in the field of reducing the size of hemispherical particles of HSG thin films, which can solve the problems of inability to form capacitors, poor step coverage of capacitive insulating films, short-circuiting of lower electrodes, etc., and achieve excellent effects. effect, improve the step coverage, suppress the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

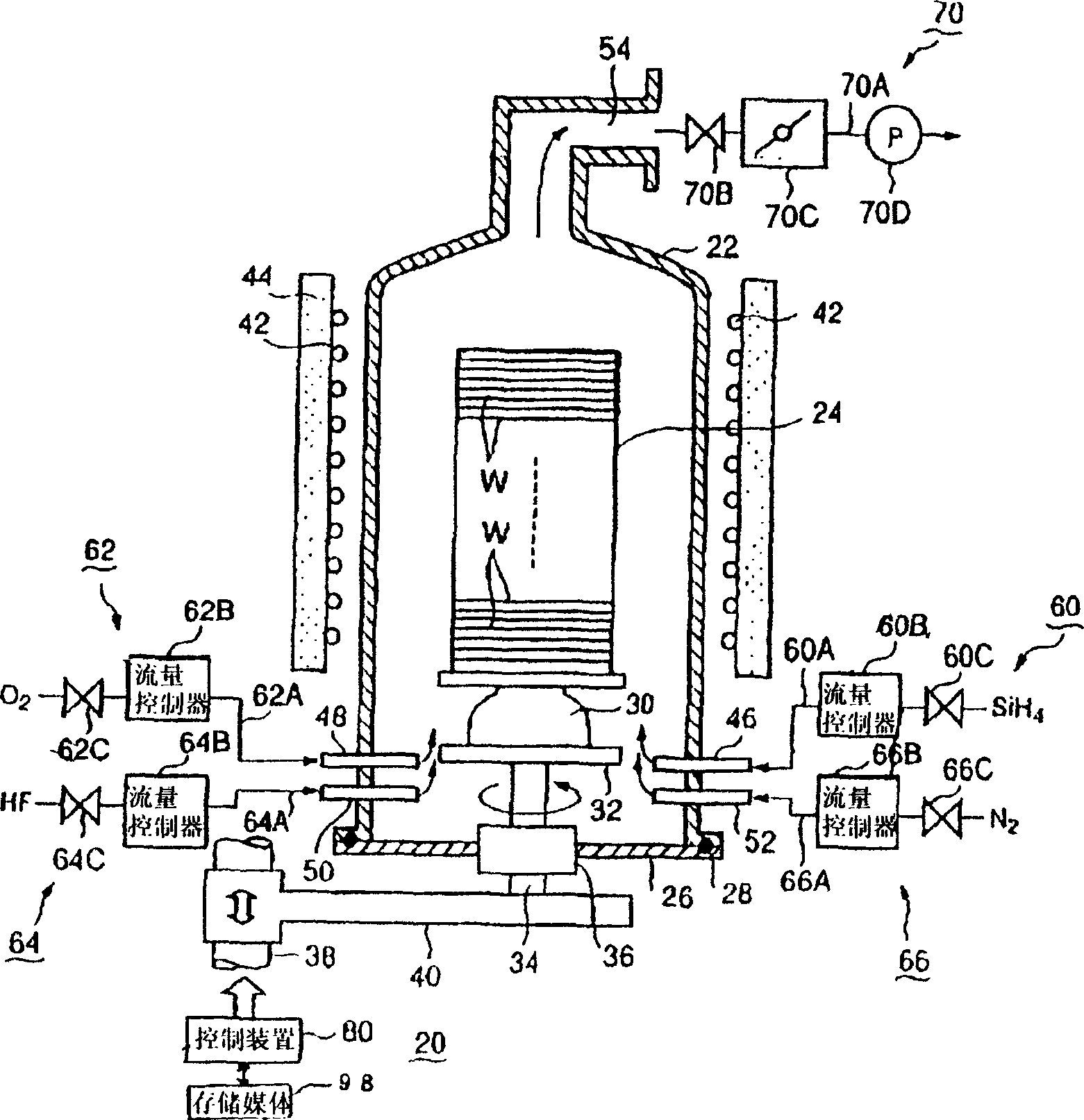

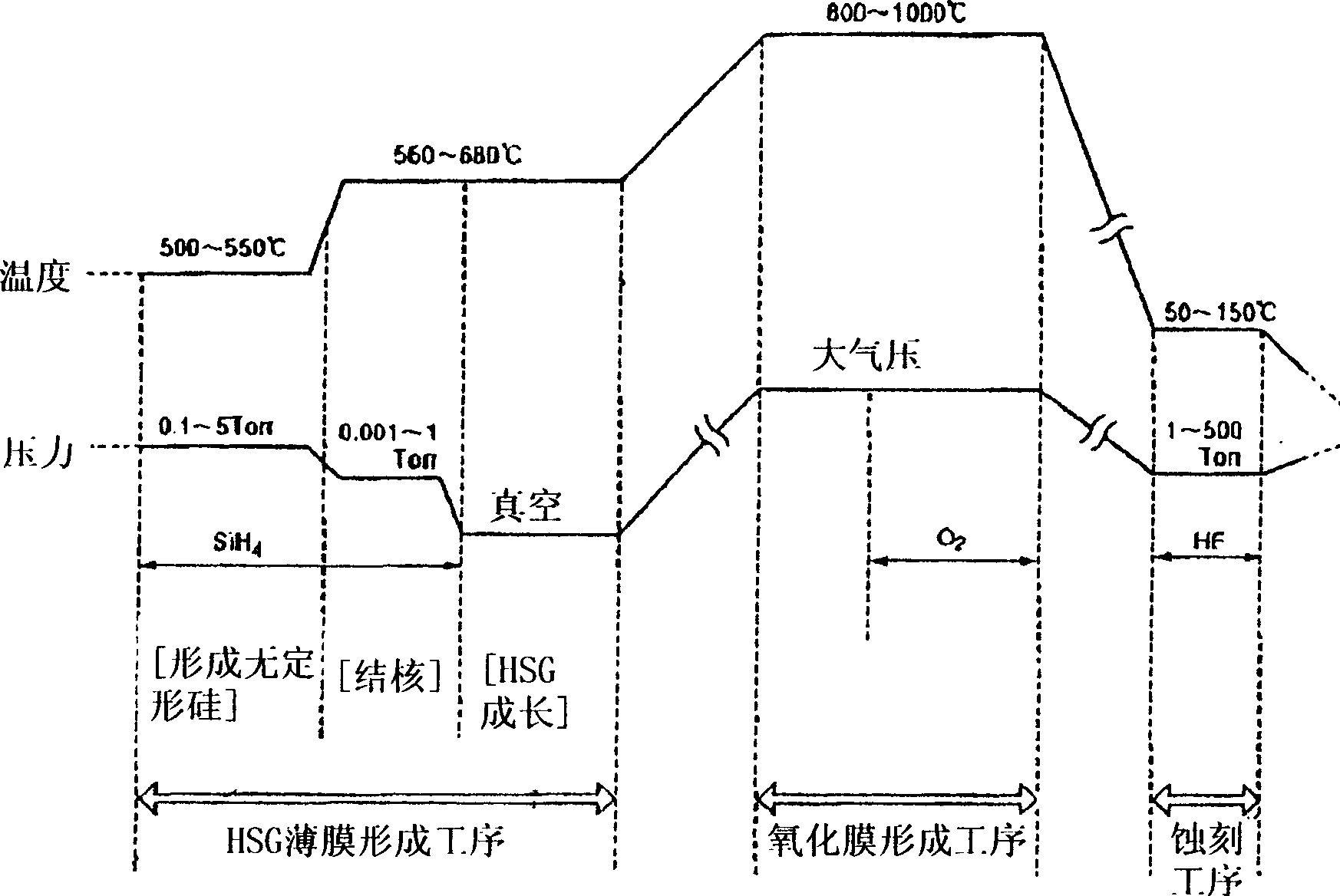

[0027] Hereinafter, an embodiment of the film forming method, film forming apparatus, and storage medium of the present invention will be described in detail based on the drawings. figure 1 is a structural diagram showing a film forming apparatus for implementing the method of the present invention, figure 2 It is a time chart representing the first embodiment flow process of the method of the present invention, image 3 It is a schematic diagram showing the formation and shape change of crystalline hemispherical particles formed by the method of the present invention.

[0028] Hereinafter, an example of an apparatus in which all of the HSG thin film forming step, oxide film forming step, and etching step can be continuously performed in this film forming apparatus will be described. As shown in the figure, the film forming apparatus 20 has a cylindrical vertical processing container 22 with an open lower end and a predetermined length in the vertical direction. The proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com