Environment protective integrated vacuum supersonic cleaning drying device

A drying device and ultrasonic technology, applied in the directions of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of insufficient cleaning and drying, increase equipment operating costs, and large surface tension, and achieve ideal Effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

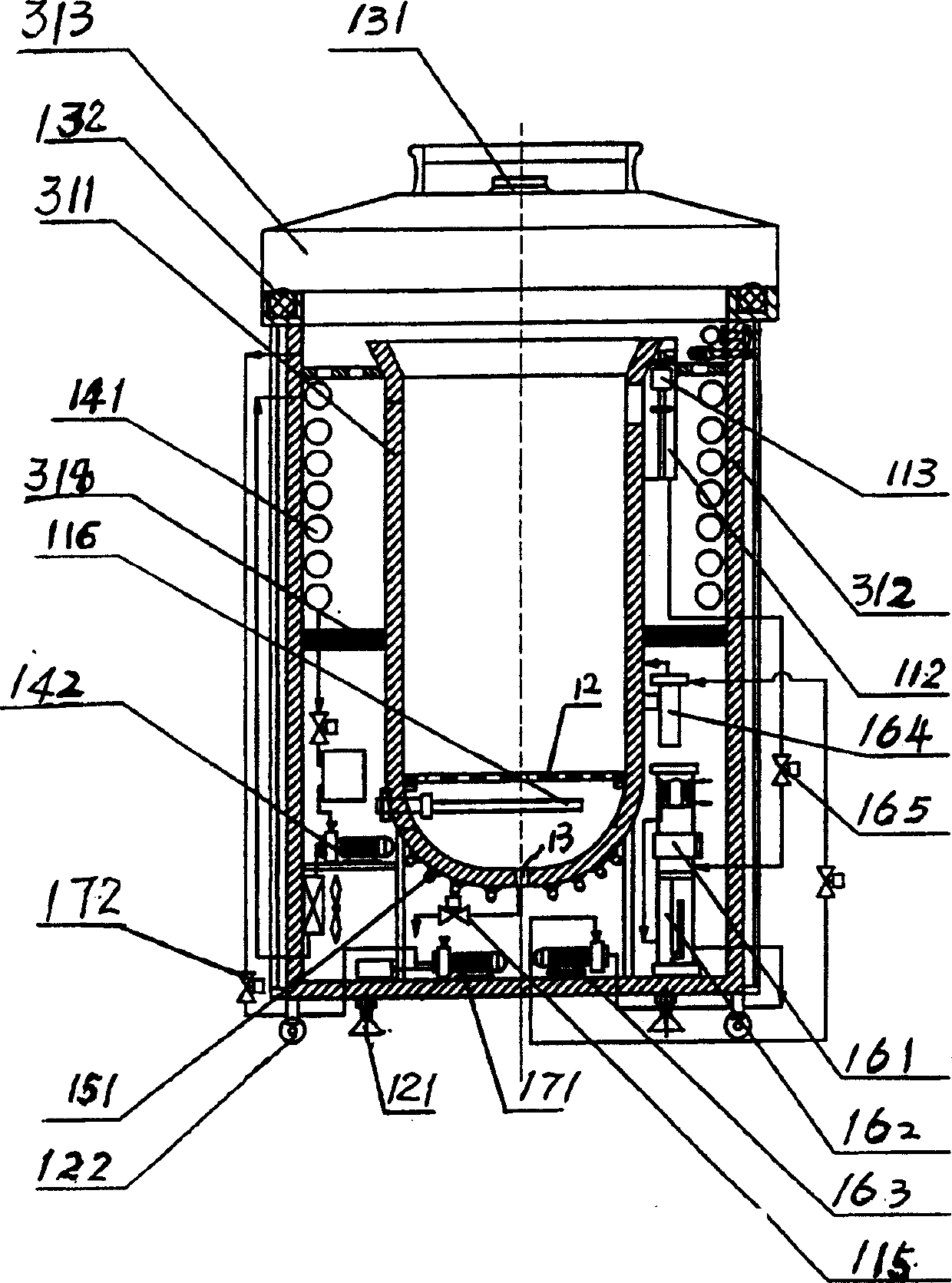

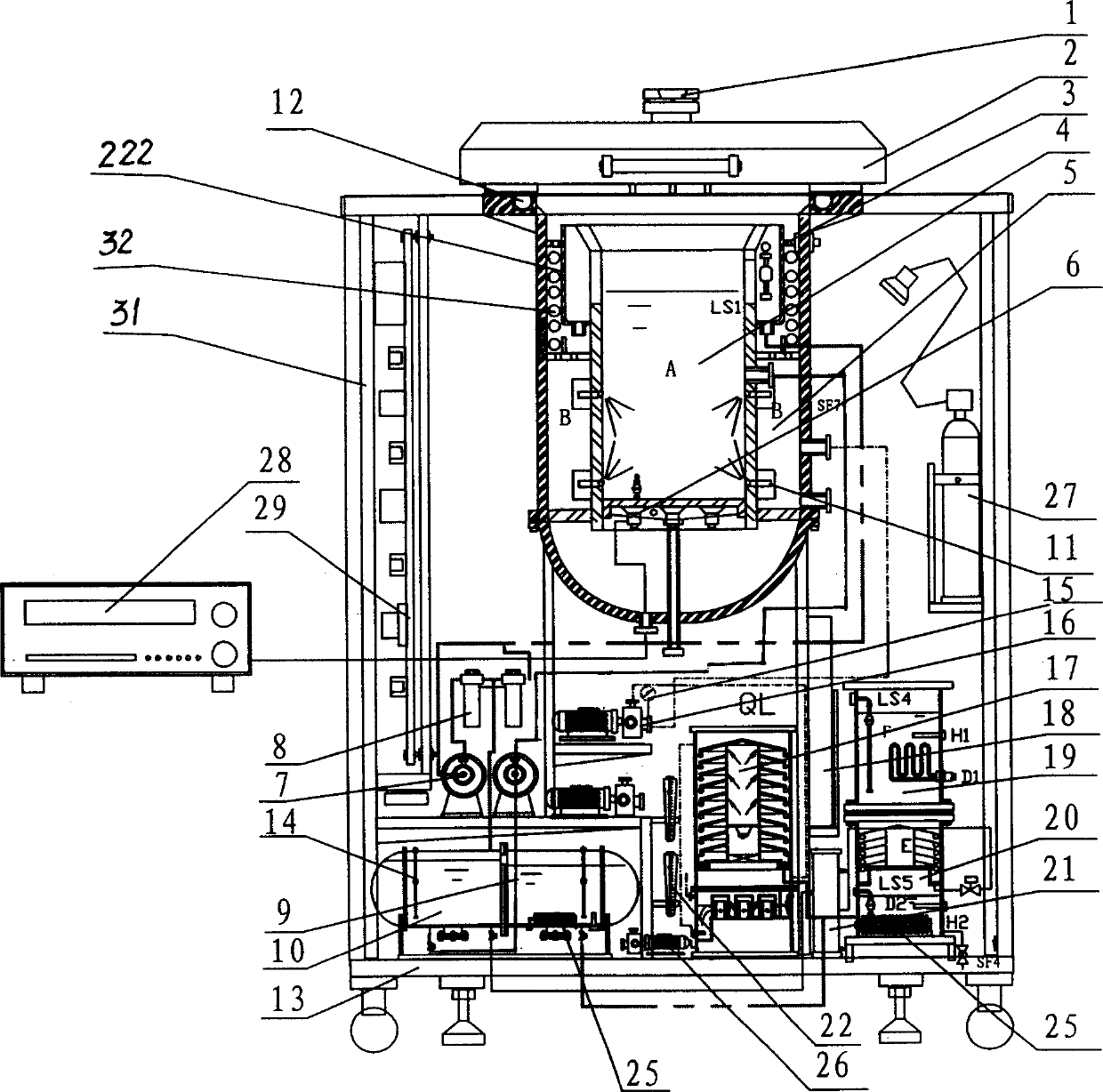

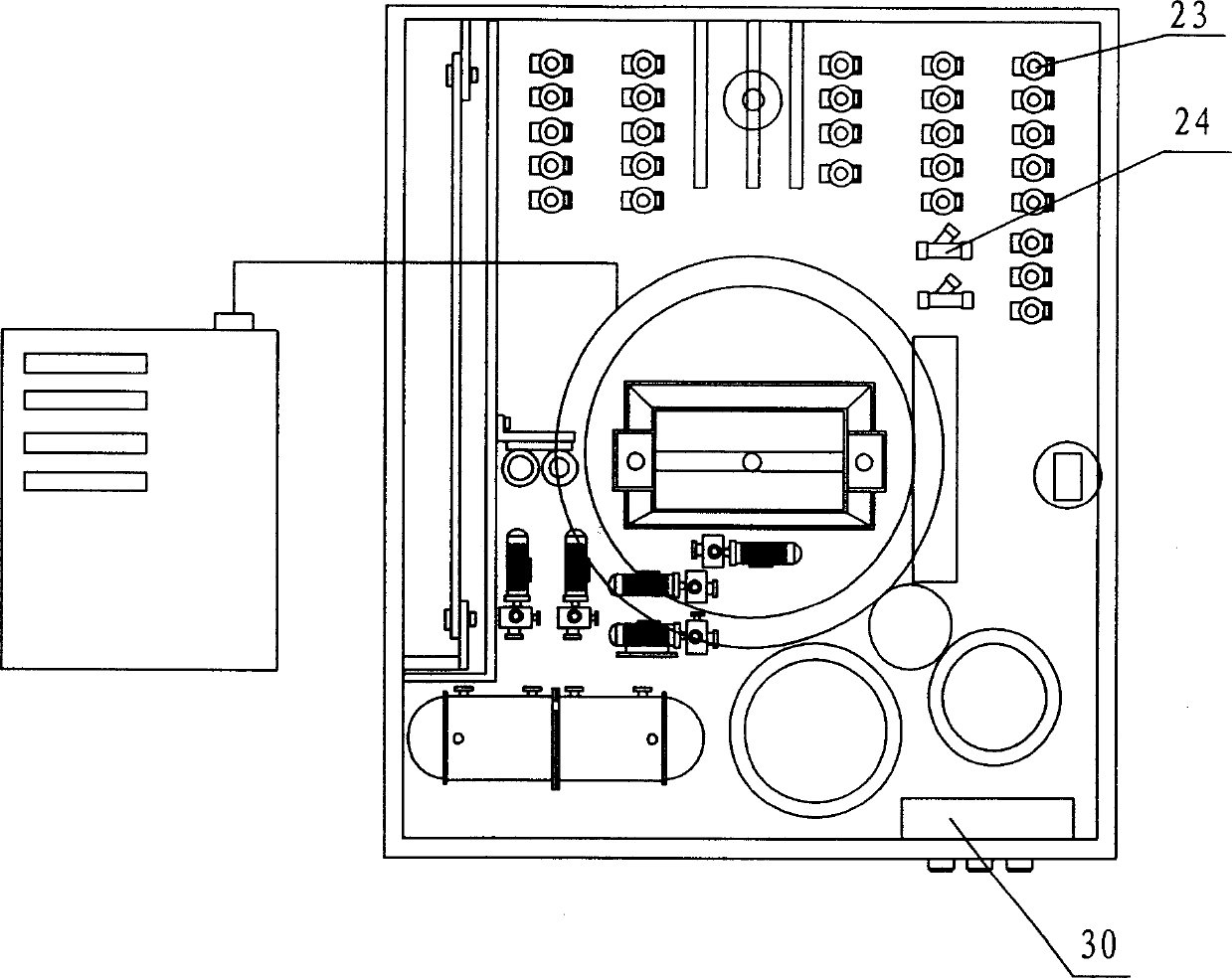

[0028]As shown in Figure 2, the present invention consists of a cleaning tank 4, a vacuum tank 5, an outer tank body 31, a sealing cover 2, a cooling mechanism, an ultrasonic generating mechanism, an internal circulation filtering mechanism, a vacuum pumping mechanism, a distillation recovery mechanism, and a thermal oil heating mechanism. , fire extinguishing mechanism and microcomputer control mechanism. The vacuum tank 5 is placed in the outer tank body 31, the cleaning tank 4 is sealed in the vacuum tank 5, a partition plate 221 is provided at the bottom of the vacuum tank 5 to separate the vacuum tank 5 into upper and lower chambers, and the cleaning tank 4 is set on the partition plate 221, the upper opening of the cleaning tank 4 communicates with the upper cavity of the vacuum tank 5, and the upper flange outer edge of the upper opening of the vacuum tank 5 is fixedly connected with the upper opening of the outer tank body 31. The upper, middle and lower parts of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com