Dirt monitoring device

A monitoring device and fouling technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of reducing the flow cross-sectional area, clogging the pipeline, reducing the operating economy of the equipment, etc., achieving easy and direct access, fouling description Intuitive, easy-to-measure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

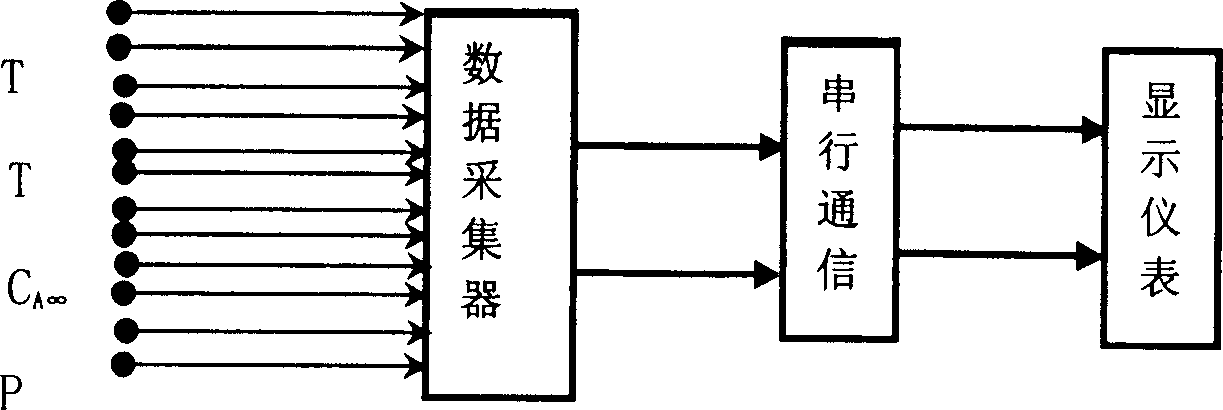

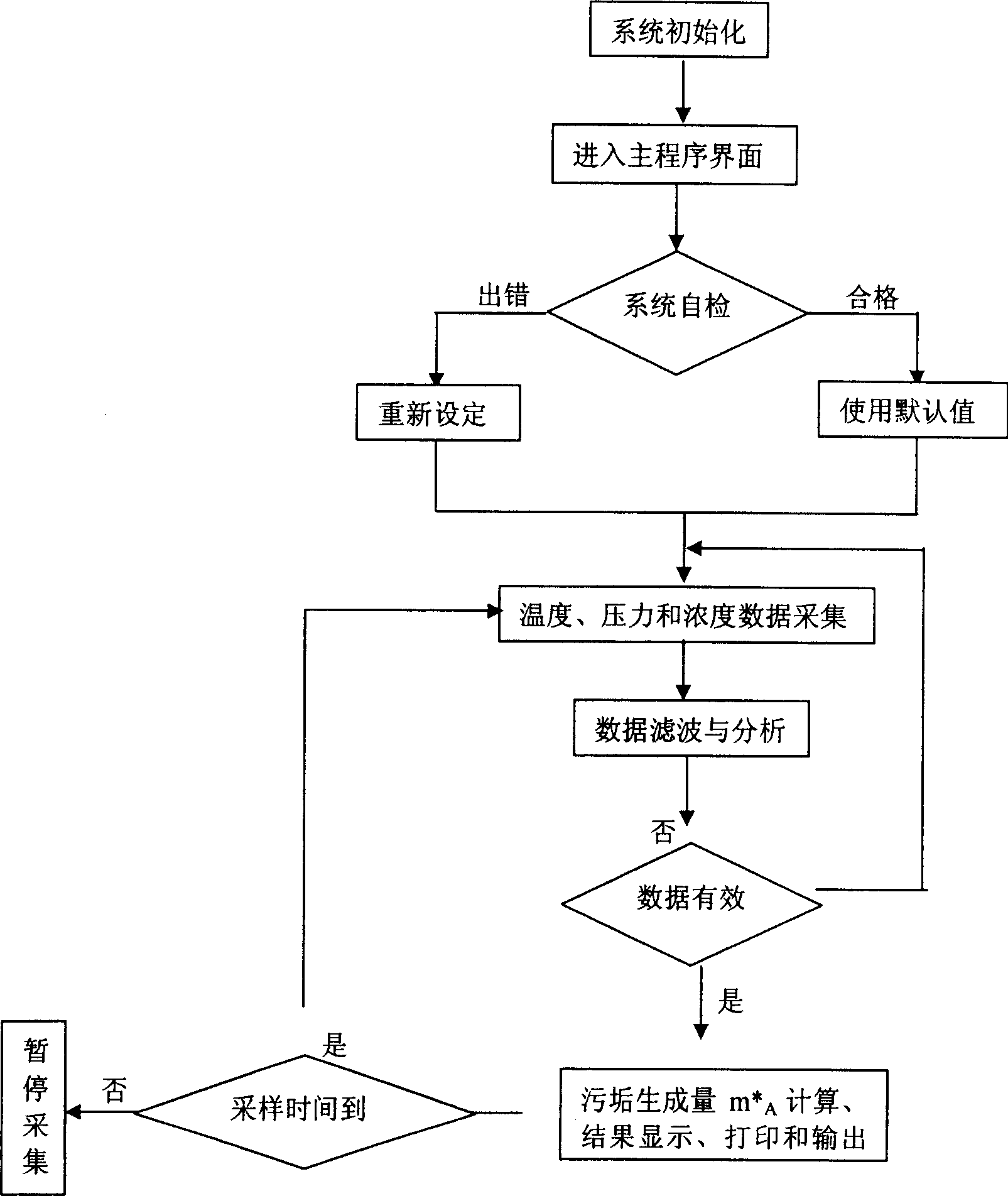

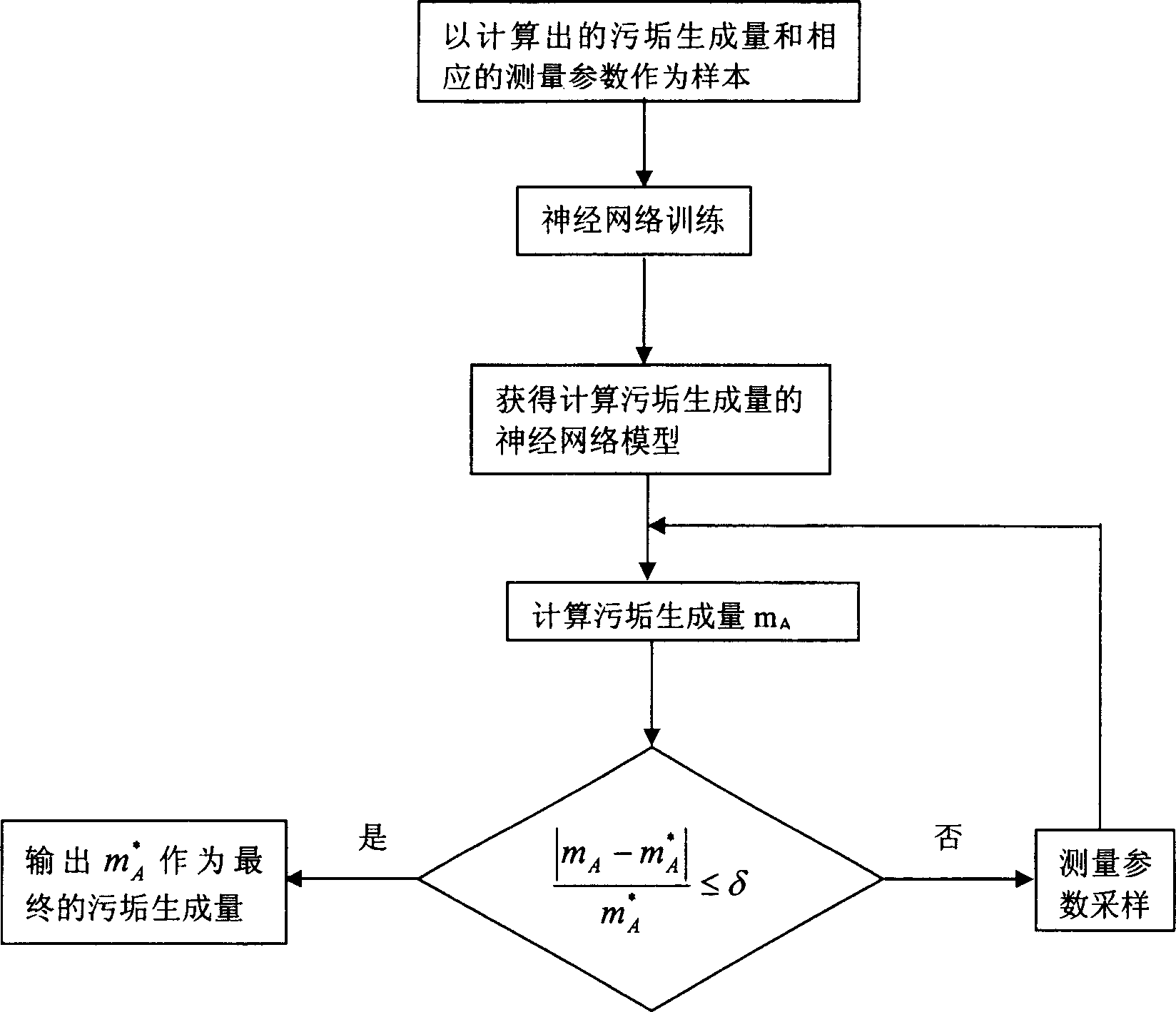

[0020] When the fluid flows in the measured pipe section, there are eight temperature measuring points arranged on the inner surface. The eight chip temperature sensors are arranged according to the principle of equal division, and can be bonded to the pipe wall along the flow direction, and the outlet points should be tightly sealed. , to prevent liquid leakage, and pay attention to the interference between the lines. An isolator can be installed as needed. The resistance signal measured by the temperature sensor is converted into a voltage signal after resistance conditioning, and then converted into a digital signal through analog-to-digital conversion. The pressure sensor is installed on the upper part of the pipe section at the entrance and exit, and the lead-out line should also prevent the fluctuation of the grounding point potential from causing the fluctuation of the analog signal. If necessary, an isolator should be installed, and the output current signal is converted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com