Touch panel

A touch panel, surface-side technology, applied in the direction of electronic equipment, applications, coatings, etc., can solve the problem that it is difficult to reliably prevent moisture intrusion or dew condensation, and achieve the effect of improving yield and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

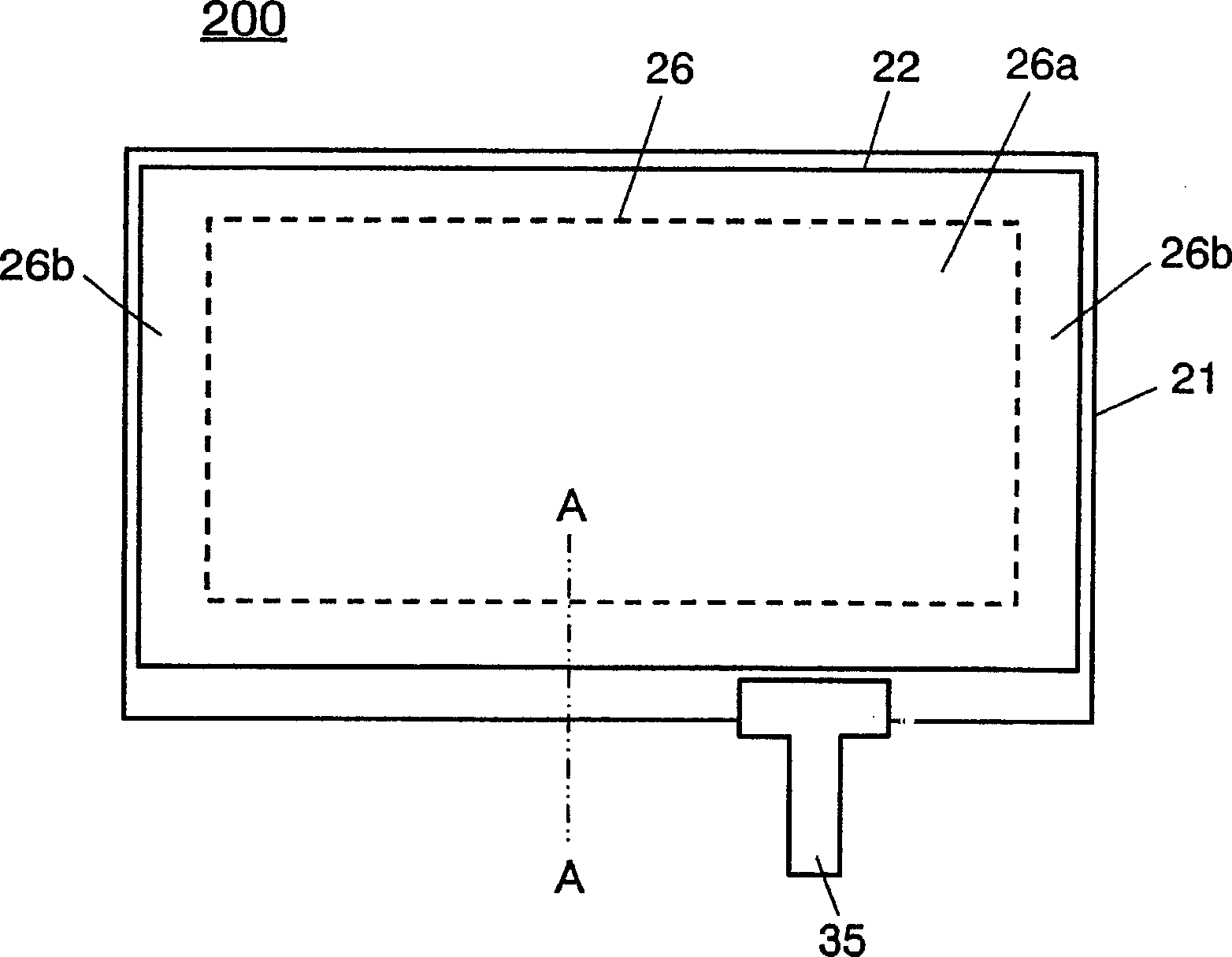

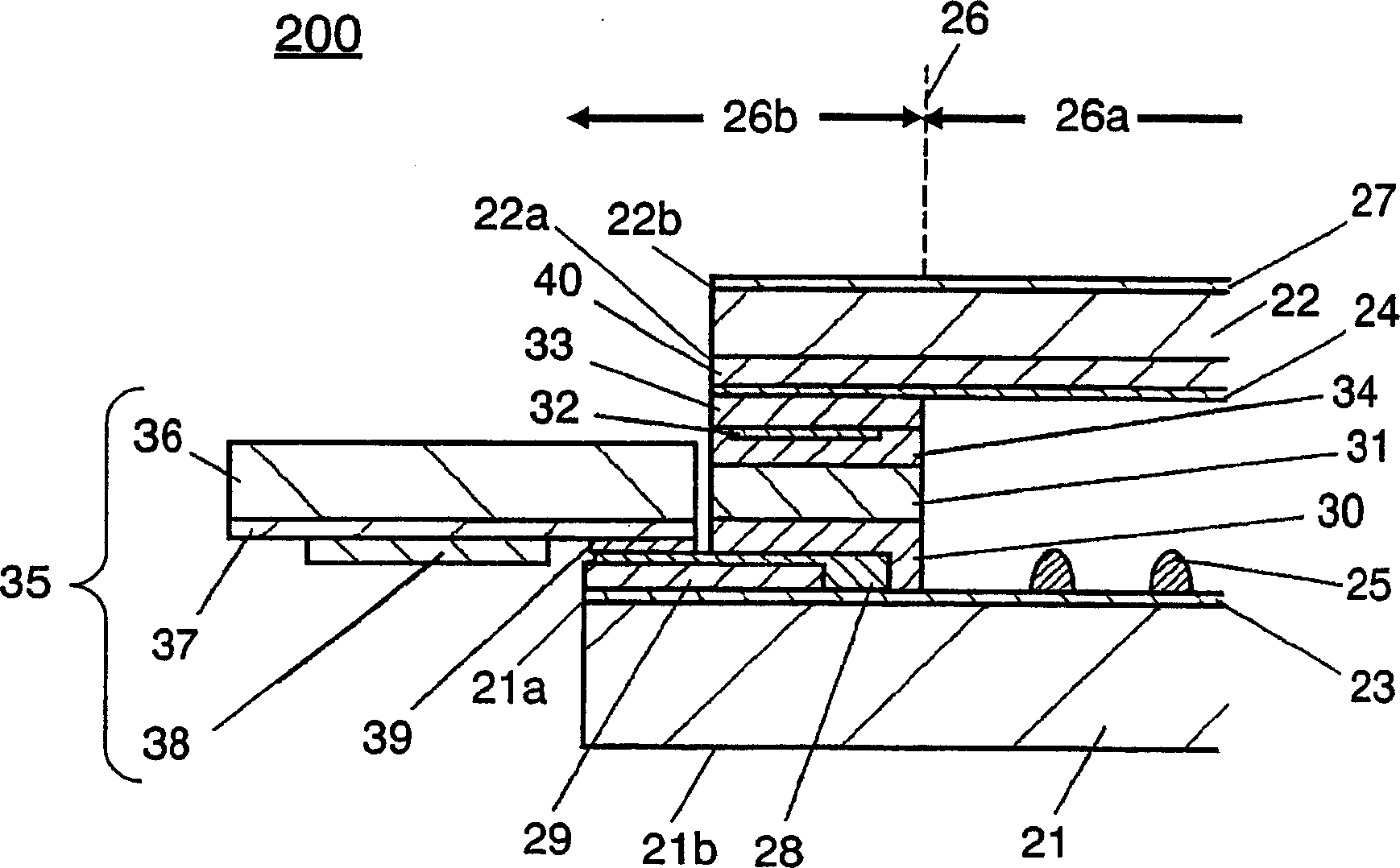

[0044] figure 1 It is a top view of touch panel 200 according to the first embodiment of the present invention. figure 2 Yes figure 1 A cross-sectional view of line A-A is shown.

[0045] The touch panel 200 includes a first transparent substrate 21 , a second transparent substrate 22 , an area boundary portion 26 , a visible area portion 26 a, a non-visible area portion 26 b and a flexible circuit board 35 . The area boundary portion 26 is in contact with the boundary of the visible area portion 26a and the non-visible area portion 26b.

[0046] exist figure 2 Among them, the touch panel 200 includes a first transparent substrate 21 made of soda glass, and a first transparent conductive film 23 made of ITO or the like is formed on the entire surface of one main surface 21a. In addition, micro-sized dot spacers 25 made of insulating epoxy resin are provided on the visible region 26 a on the first transparent conductive film 23 at a predetermined pitch.

[0047] The to...

no. 2 approach

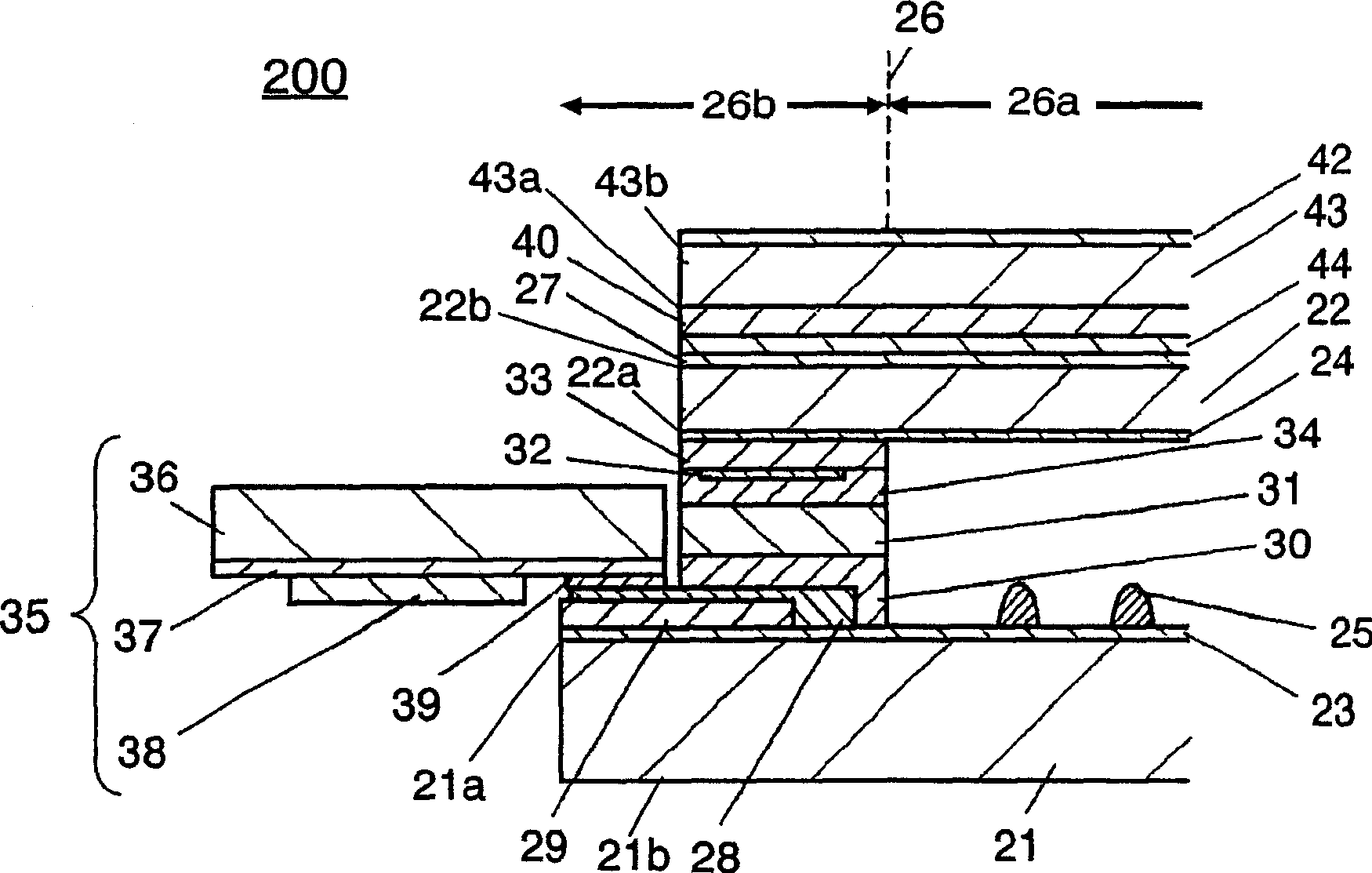

[0080] image 3 It is a cross-sectional view of the touch panel according to the second embodiment of the present invention. Components that are the same as those in the first embodiment are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0081] The touch panel of the second embodiment is the same as the first embodiment in that the water vapor transmission preventing layer 40 is arranged on the second transparent substrate 22 having a polymer thin film structure, but differs in design and the like.

[0082] That is, if image 3 As shown, the second transparent conductive film 24 is formed on one main surface 22a of the second transparent substrate 22 in the second embodiment, and the hard coat layer 27 is formed on the other main surface 22b. On the other hand, the water vapor transmission preventing layer 40 is arranged on a polymer film 43 different from the second transparent substrate 22, and the polymer film 43 is pasted on t...

no. 3 approach

[0092] Figure 4 is a cross-sectional view of a touch panel according to a third embodiment of the present invention. Parts having the same structure as those of the second embodiment are denoted by the same symbols, and detailed description thereof will be omitted.

[0093] The touch panel of the third embodiment is substantially the same as that of the second embodiment in that the water vapor transmission preventing layer 40 is disposed on the other main surface 22b of the second transparent substrate 22 made of a polymer film. The designs are different. like Figure 4 As shown, the second transparent conductive film 24 is provided on one main surface 22a of the second transparent substrate 22, and the hard coat layer 27 is formed on the other main surface 22b, as in the second embodiment.

[0094] Furthermore, in the touch panel of the third embodiment, a glass plate 50 with a thickness of 0.2 mm that functions as the water vapor transmission preventing layer 40 is bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com