High efficiency machine for cutting metallic wire

A metal wire and wire breaking machine technology, which is applied in the field of high-efficiency wire breaking machines for metal wires, can solve the problems of inability to press down to cut multiple metal wires at the same time, low efficiency, slow cutting speed, etc., to save manpower, high efficiency, Cut off the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

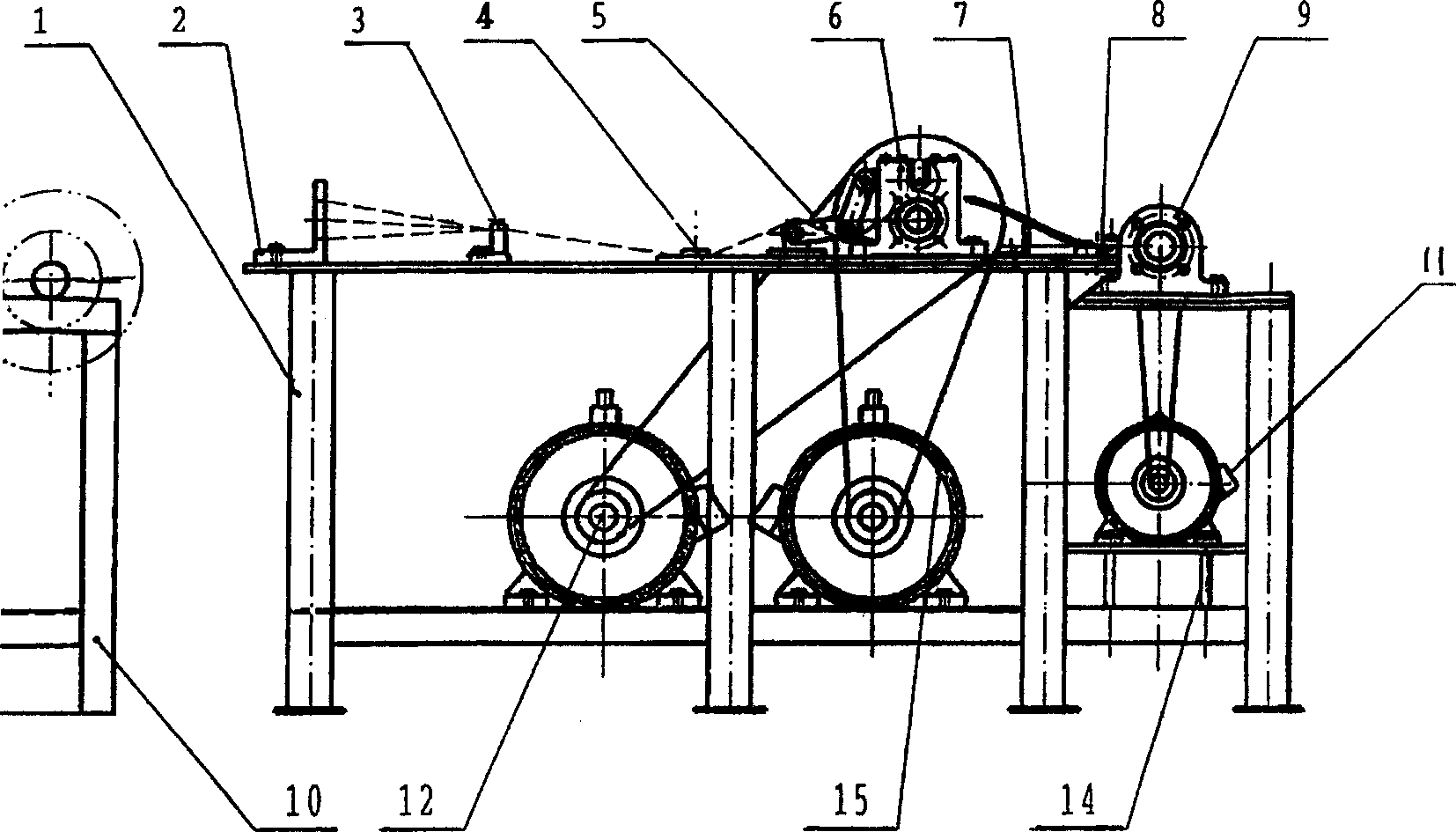

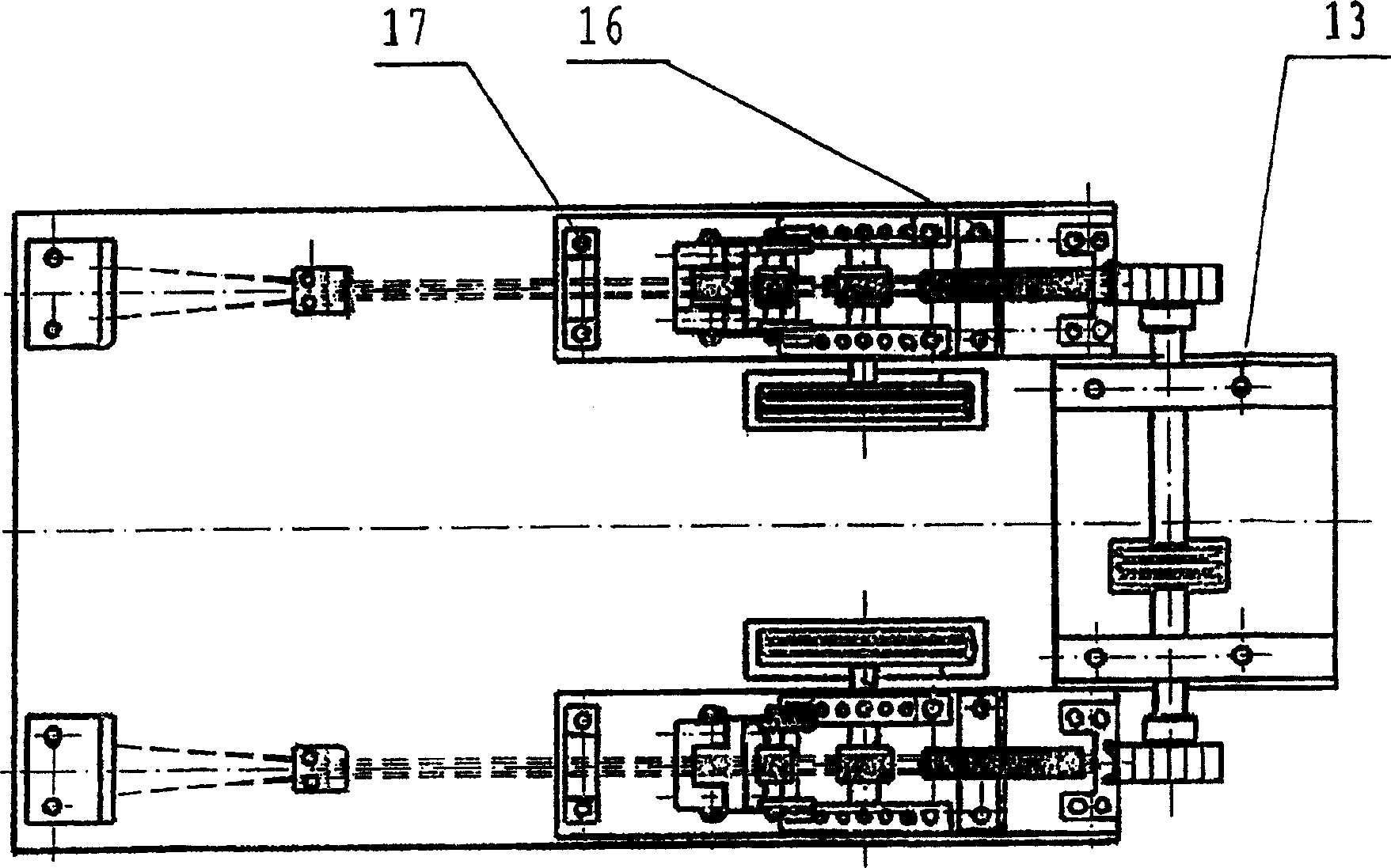

[0020] Embodiment 1: This wire breaking machine has a frame 1, and the frame 1 is connected with a wire trimmer and a wire feeding device, and one end of the frame 1 is connected with a wire breaker 9, and the other end is connected with a material tray device 10. The bottom of the frame 1 is connected with motors 14, 15 and 12, wherein the motors 15 and 12 are speed-regulating motors.

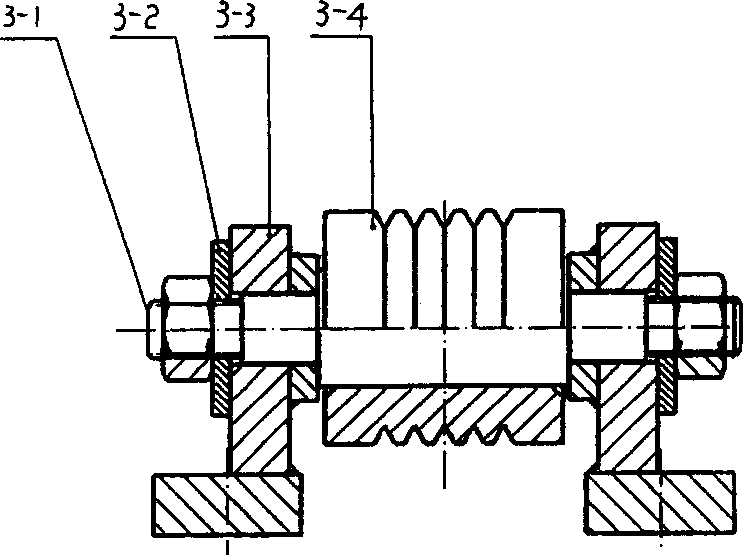

[0021] The wire trimming device is composed of a wire drawing die 2, a front wire trimming die 3 and a rear wire trimming die 4. The wire drawing die 2, the front wire trimming die 3 and the rear wire trimming die 4 are arranged and installed on the frame 1 in sequence; the wire drawing die 2 has a " L" shaped bracket with wire drawing holes on the bracket; the front wire trimming die 3 has an "L" shaped bracket with wire trimming holes on the bracket; the rear wire trimming die 4 is composed of upper die and lower die Both are two flat plates stacked together, and there are holes on the end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com