Device for altering the valve timing in an internal combustion engine

A technology for controlling time and ventilation valves, applied in valve devices, engine control, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

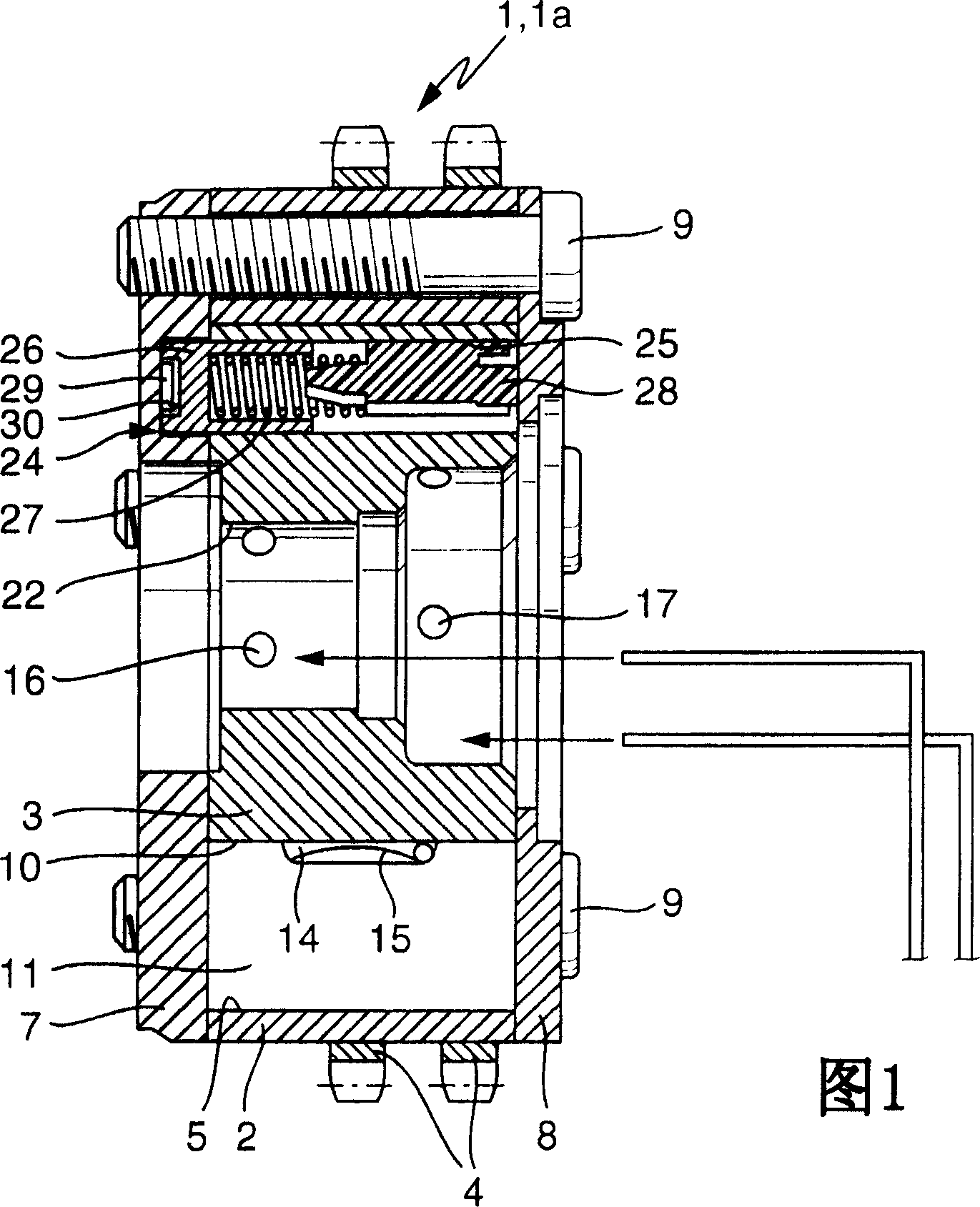

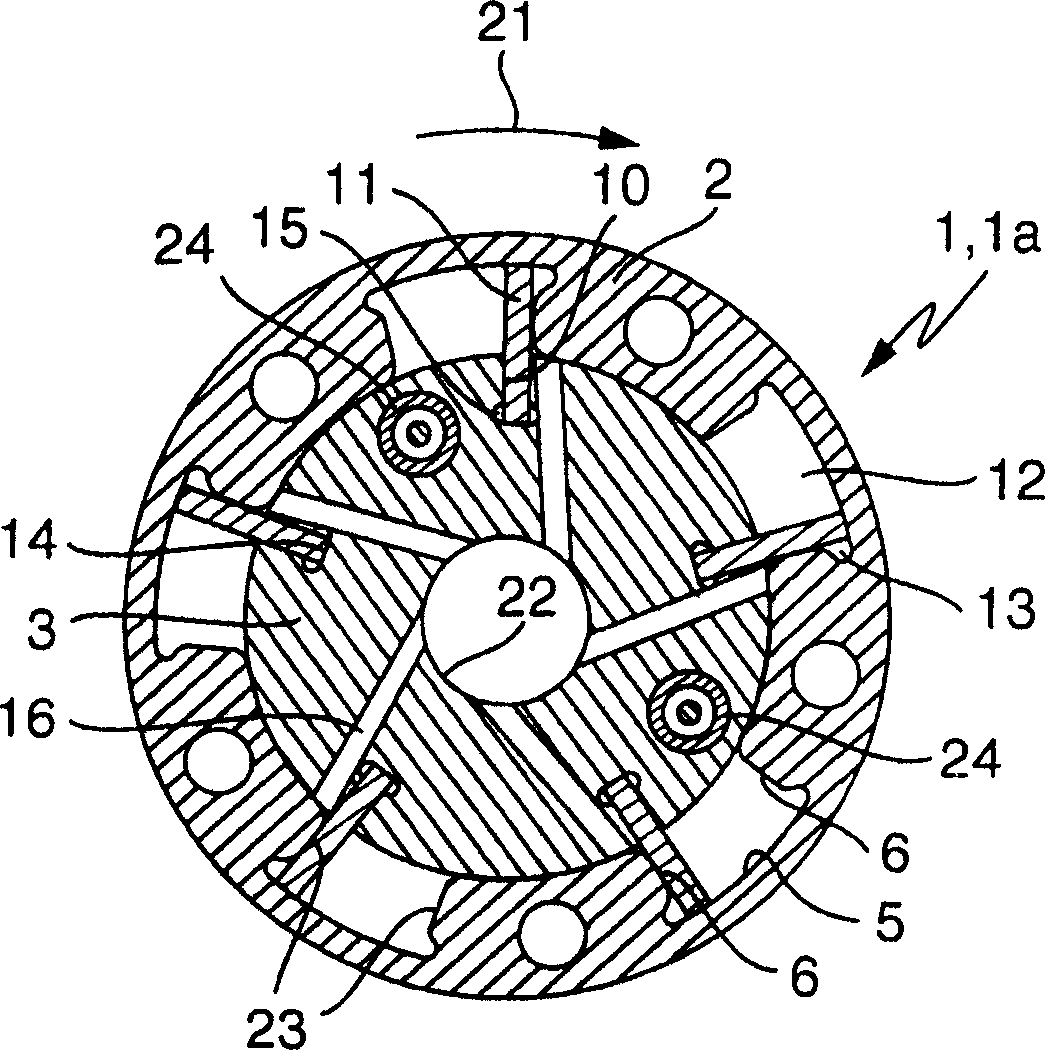

[0047] 1 and 2 show a hydraulic adjustment device 1 a of a device 1 for varying the actuation times of gas exchange valves of an internal combustion engine. The adjusting device 1 a essentially consists of a stator 2 and a rotor 3 arranged concentrically therewith. The drive wheel 4 is connected to the stator 2 in a rotationally fixed manner and is designed as a sprocket in the illustrated embodiment. Likewise the embodiment of the drive wheel 4 can be a pulley or a gear. The stator 2 is rotatably mounted on the rotor 3 , wherein in the illustrated embodiment the inner peripheral surface of the stator 2 is provided with five gaps 5 spaced from one another in the circumferential direction. The gap 5 is limited in the radial direction by the stator 2 and the rotor 3 , in the circumferential direction by the two side walls 6 of the stator 2 and in the axial direction by the first side cover 7 and the second side cover 8 . Each gap 5 is hermetically closed in this way. The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com