Electronic photographic toner and imaging method

一种电子照相、调色剂的技术,应用在电子照相调色剂和成像领域,能够解决难以获得耐热性(耐升华性和耐光性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

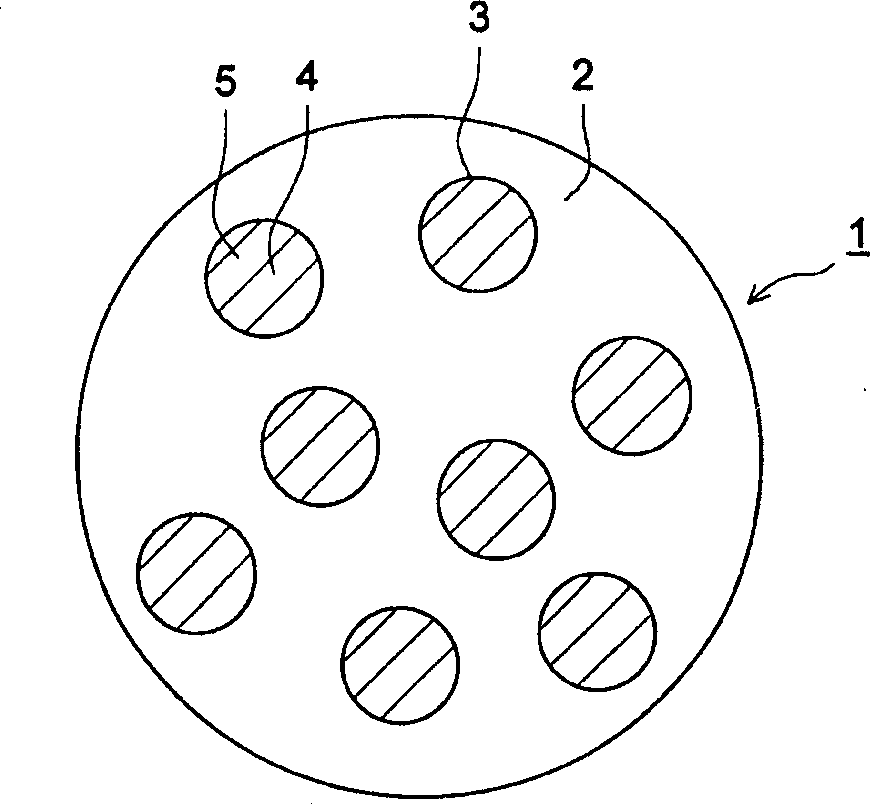

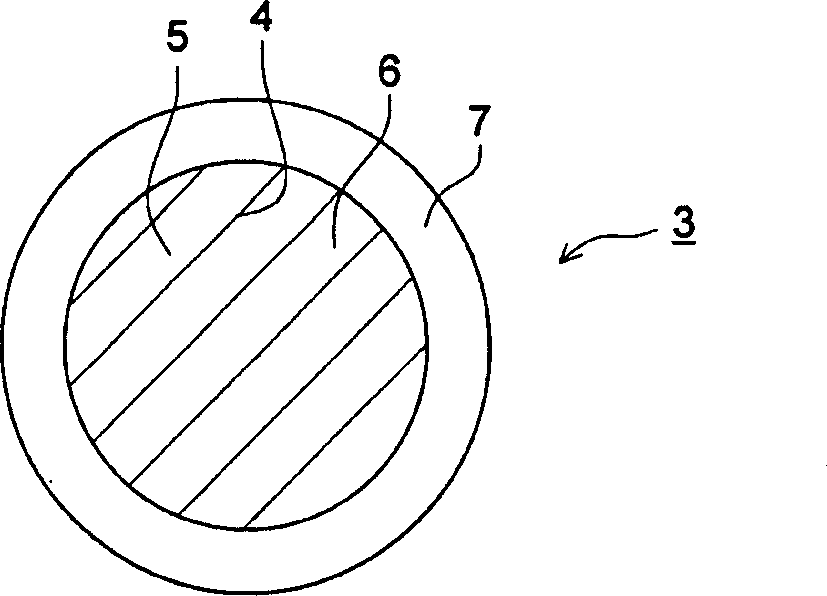

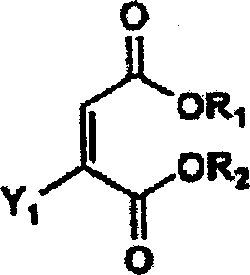

[0025] The preparation of the colored microparticles relating to the present invention will now be described.

[0026] Colored fine particles can be obtained by dissolving (or dispersing) a resin and a dye in an organic solvent and emulsifying them in water, followed by removing the organic solvent. When covered with a shell resin (shell), a polymerizable monomer containing an unsaturated double bond is added thereto and emulsion polymerization is performed in the presence of a surfactant. Therefore, simultaneously with the polymerization reaction, deposition on the surface of the core is performed to obtain colored fine particles having a core / shell structure. Colored fine particles can be obtained by various methods. For example, an aqueous dispersion of resin particles is previously formed by emulsion polymerization, and then, an organic solvent solution containing a dye is added to the aqueous dispersion of resin particles to impregnate the dye into the resin particles to...

Embodiment

[0120] The invention is further described on the basis of examples, but by no means limited thereto.

[0121] colored particles

[0122] Preparation of Dispersion of Colored Microparticles 1

[0123]Into the separable flask were charged 13.5 g of resin (P-1), 16.3 g of dye (A-1) and 123.5 g of acetic acid, and after replacing the inner atmosphere with nitrogen, the dye was completely dissolved under stirring. Further, 238 g of an aqueous solution of 8.0 g of AQUALON KH-50 (manufactured by DAIICHI SEIYAKU CO., LTD.) was added dropwise thereto with stirring and then emulsified using CLEAR-MIX W-MOTION CLM-0.8W (manufactured by M-TECHNIQUE Co.) 300 seconds. Then, acetic acid was removed under reduced pressure to obtain a dispersion of colored fine particles 1 containing the dye. In the dispersion thus obtained, the volume average particle diameter of the colored particles was 30 nm. Hereinafter, the volume average particle diameter is measured using ZETASIZER (Marbahn Co.). ...

example 1 and 2

[0191] To each of the toner particles 1 to 11, 1% by weight and 1.2% by weight of hydrophobic silica (having a number-average particle diameter of 12 nm and a degree of hydrophobicity of 68) and hydrophobic titanium (having a number-average particle diameter of 20 nm and degree of hydrophobicity 63), and mixed for 15 minutes using a Henschel mixer manufactured by Mitsui Miike Kako-sha. Then, coarse particles were removed using a sieve having an opening of 45 μm to obtain Toners 1 to 11 . These are also referred to as "Inventions 1 to 9" and "Comparative Examples 1 and 2".

[0192] Preparation of developer

[0193] A silicone resin-covered ferrite carrier having a volume average particle diameter of 60 μm was mixed with each of the foregoing toners 1 to 11 at a toner content of 6% by weight to obtain “Developers 1” to “ Developer 11".

[0194] Evaluate

[0195] A digital copier Konica 7075 (manufactured by Konica Minolta Business Technology, Inc.) was used as an evaluation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com