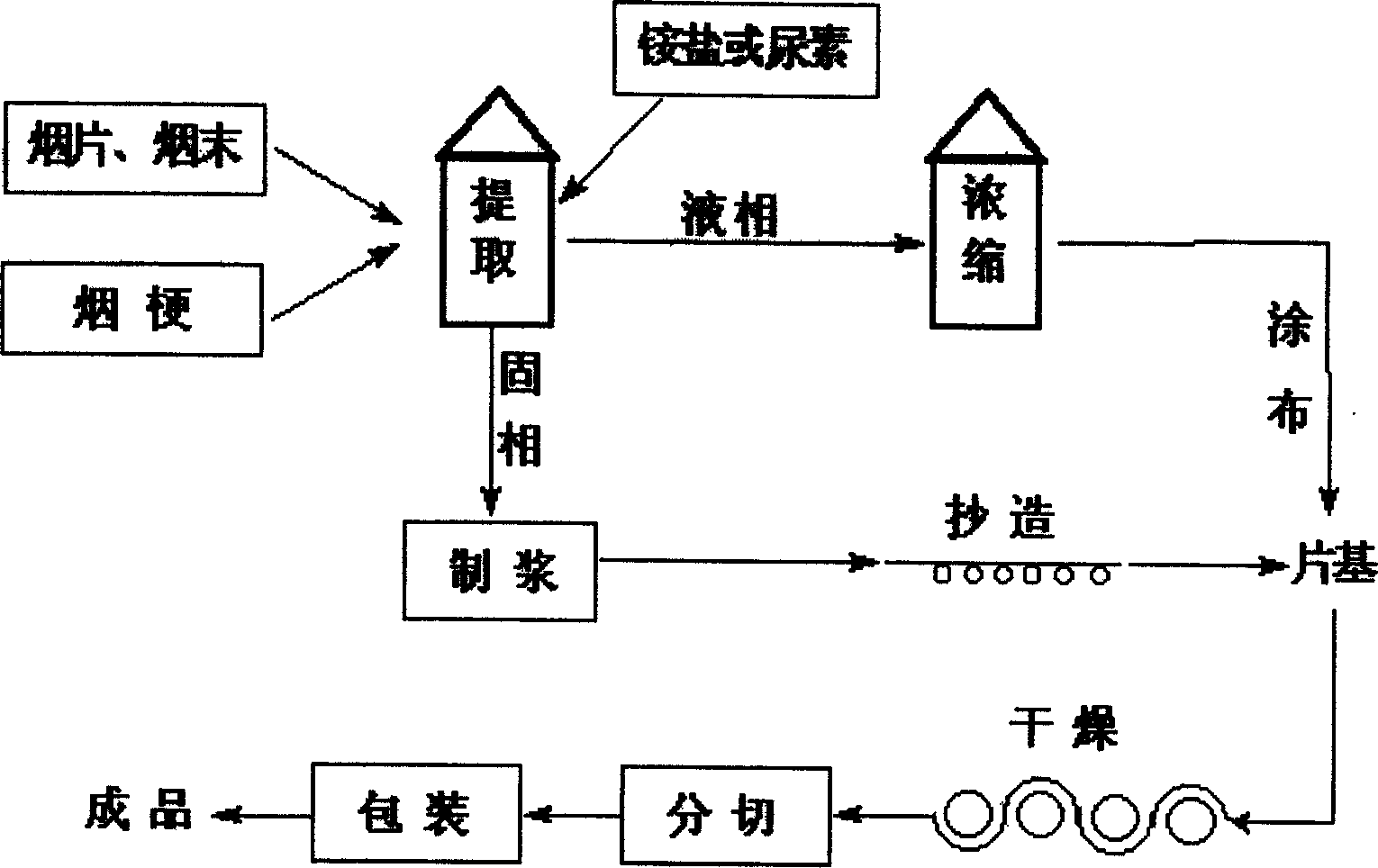

Method for preparing reconstituted tobacco leaves through paper making method

A technology of reconstituted tobacco leaves and papermaking, which is applied in the field of preparation of reconstituted tobacco leaves, and can solve the problems of less reconstituted tobacco leaves, inability to produce reconstituted tobacco leaves, and severe process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

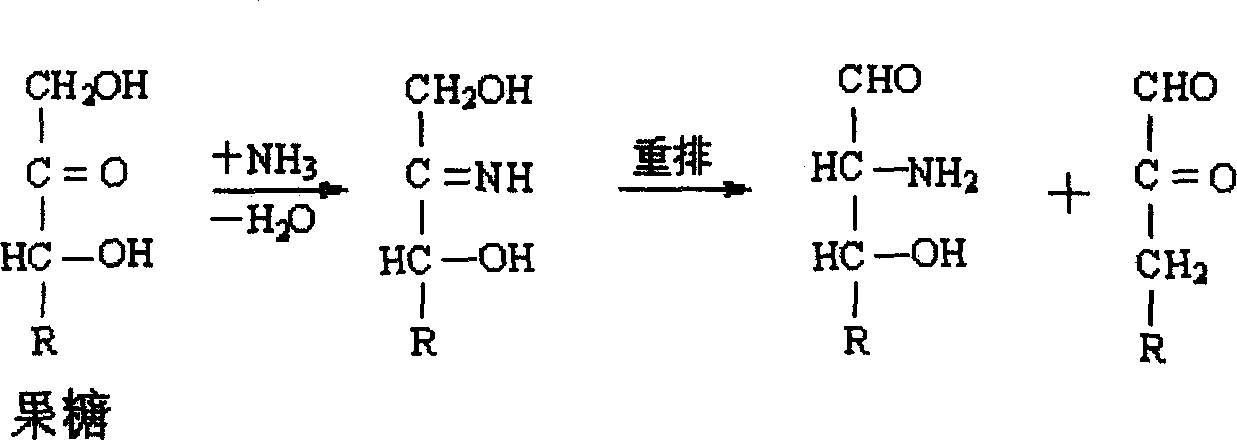

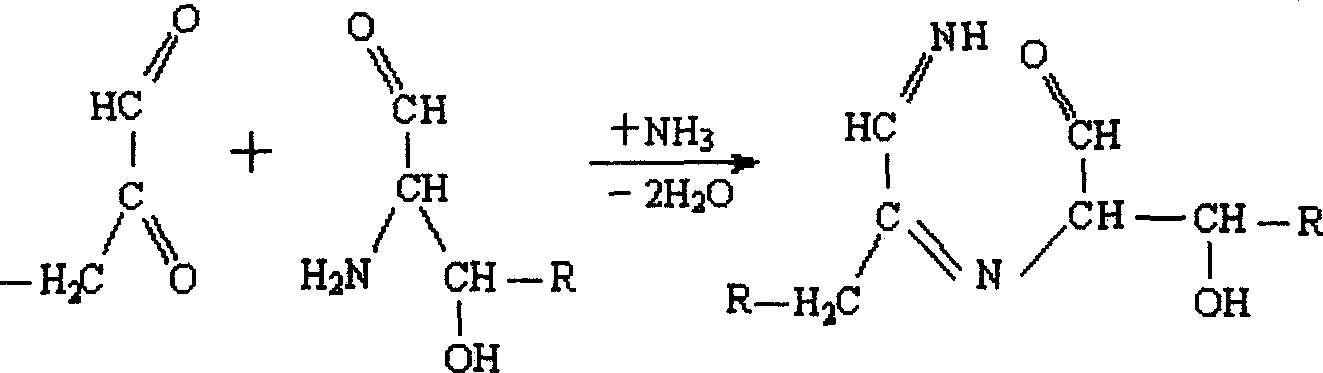

Method used

Image

Examples

Embodiment 1

[0043] Put 0.04 parts of diammonium hydrogen phosphate in 6 parts of water, stir and dissolve; respectively put 0.65 parts of tobacco stems and 0.35 parts of broken tobacco pieces, and the above solution in a sealed container for 50 minutes, set the temperature at 60 °C, The pH value is 7.5; the soaked material obtained is separated into liquid phase and solid phase part by centrifugal separation equipment; the solid phase part is dissociated into a slurry with a beating degree of 30°SR by a beater, and the slurry is diluted with water to 1 The concentration of % is made into a continuous film base with a fourdrinier paper machine; the moisture content of the film base is 20%. The liquid phase part is concentrated to 1.25g / cm by vacuum evaporation equipment 3 concentration, and then coated on the base, the coated base contains 45% soluble matter (dry weight). Then it is dried in a drying cylinder to a moisture content of 12%, and the product is obtained after cutting and pack...

Embodiment 2

[0045] Example 1 was repeated with the following differences: the composition of the tobacco material was 0.7 parts tobacco stems and 0.3 parts tobacco shreds. 0.04 parts of ammonium acetate and 0.02 parts of urea, the pH value is 6. The extract is separated from the solid phase by a twin-screw extrusion device, and then the solid phase is dissociated into a slurry with a beating degree of 25°SR by a beater, and diluted with water to a concentration of 1%. Then use a fourdrinier paper machine to make a sheet base, and the moisture content of the sheet base is 25%. Extract concentrated to 1.20g / cm 3 Concentration, then coated on the film base, the coated film base contains 40% soluble matter (absolute dry weight), then dried, cut and packaged.

Embodiment 3

[0047] Repeat Example 1, with the following differences: immerse the tobacco material in a sealed tank with water at 80°C for 30 minutes, the tobacco material consists of 0.55 parts of tobacco stems, 0.30 parts of shredded tobacco flakes and 0.15 parts of tobacco dust, and 10 parts of water , 0.02 parts of ammonium carbonate to adjust the pH value to 6. The solid phase is dissociated into a slurry with a beating degree of 35°SR with a disc refiner, and the slurry is diluted with water to a concentration of 0.8%, and then made into a sheet base with a fourdrinier paper machine, and the moisture content of the sheet base is 25%. Extract concentrated to 1.25g / cm 3 concentration, and then coated on the base, the coated base contains 40% soluble matter (dry weight). It is then dried, cut and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com