A tool, a cutting insert, a shim and use of the cutting insert

A technology for cutting blades and cutting tools, which is applied in the direction of cutting blades, accessories of toolholders, and tools used in lathes, etc., and can solve problems such as static instability of support points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

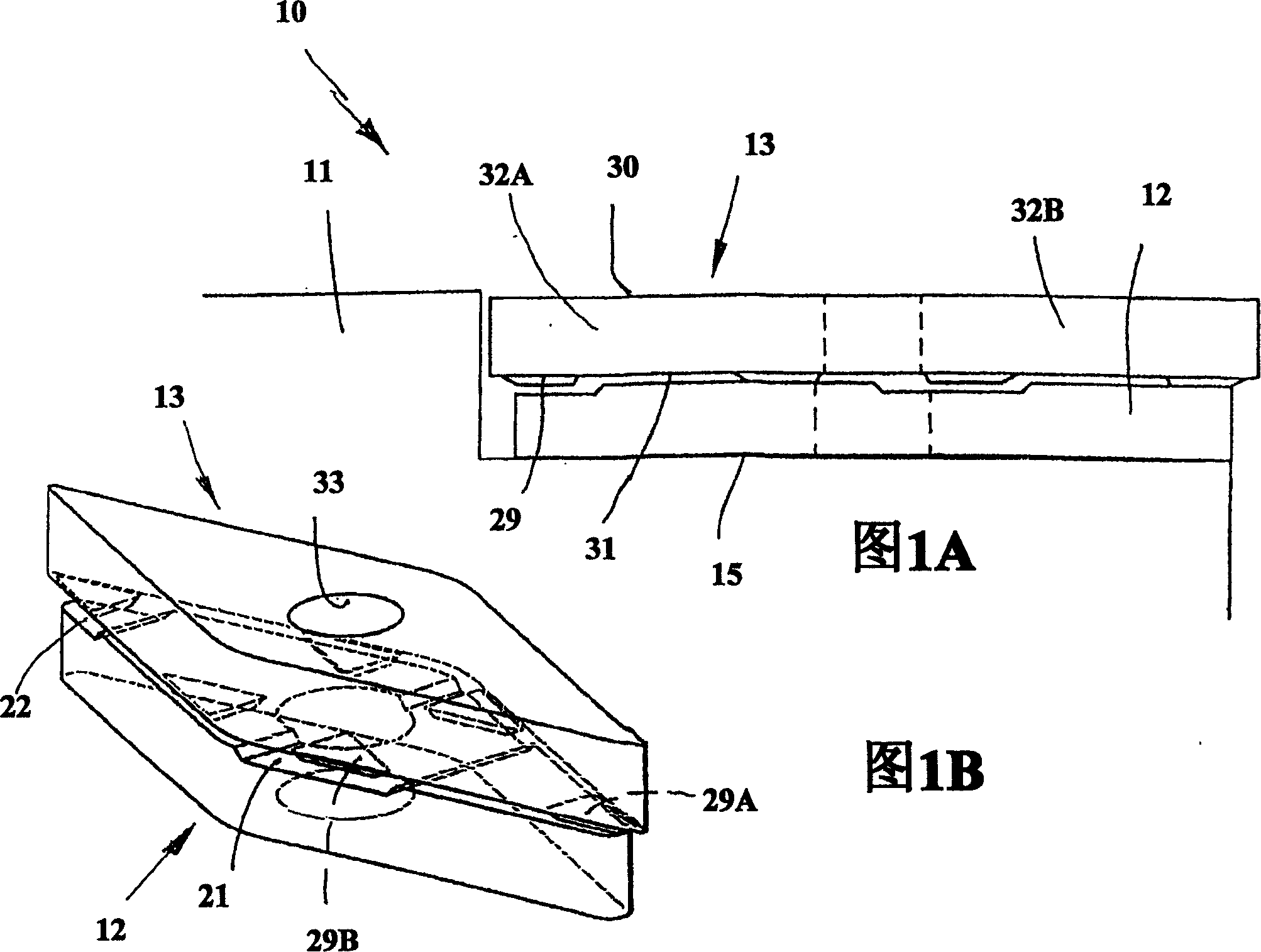

[0016] The tool 10 shown in FIGS. 1A and 1B comprises a tool holder 11 for turning or milling, a spacer 12 and an indexable cutting insert 13 made of cemented carbide. The cutting insert 13 and the spacer comprise through holes so that they can be firmly fixed against the tool holder in a conventional manner by means of screws not shown here. Alternatively, conventional clamps can also be used.

[0017] The knife holder 11 may be a square knife handle, and has a recess for mounting a spacer. The recess comprises at least two raised shoulders against which the edge surface of the cutting insert can abut.

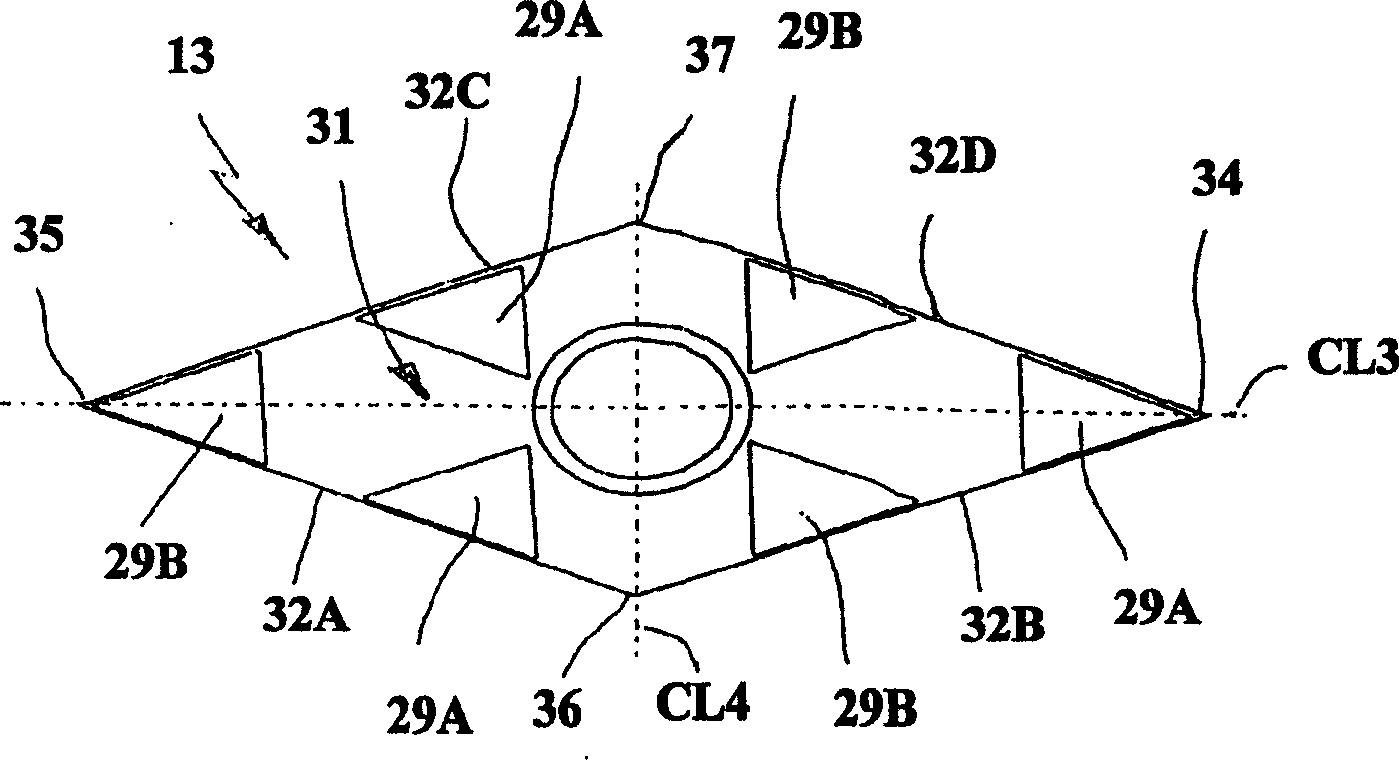

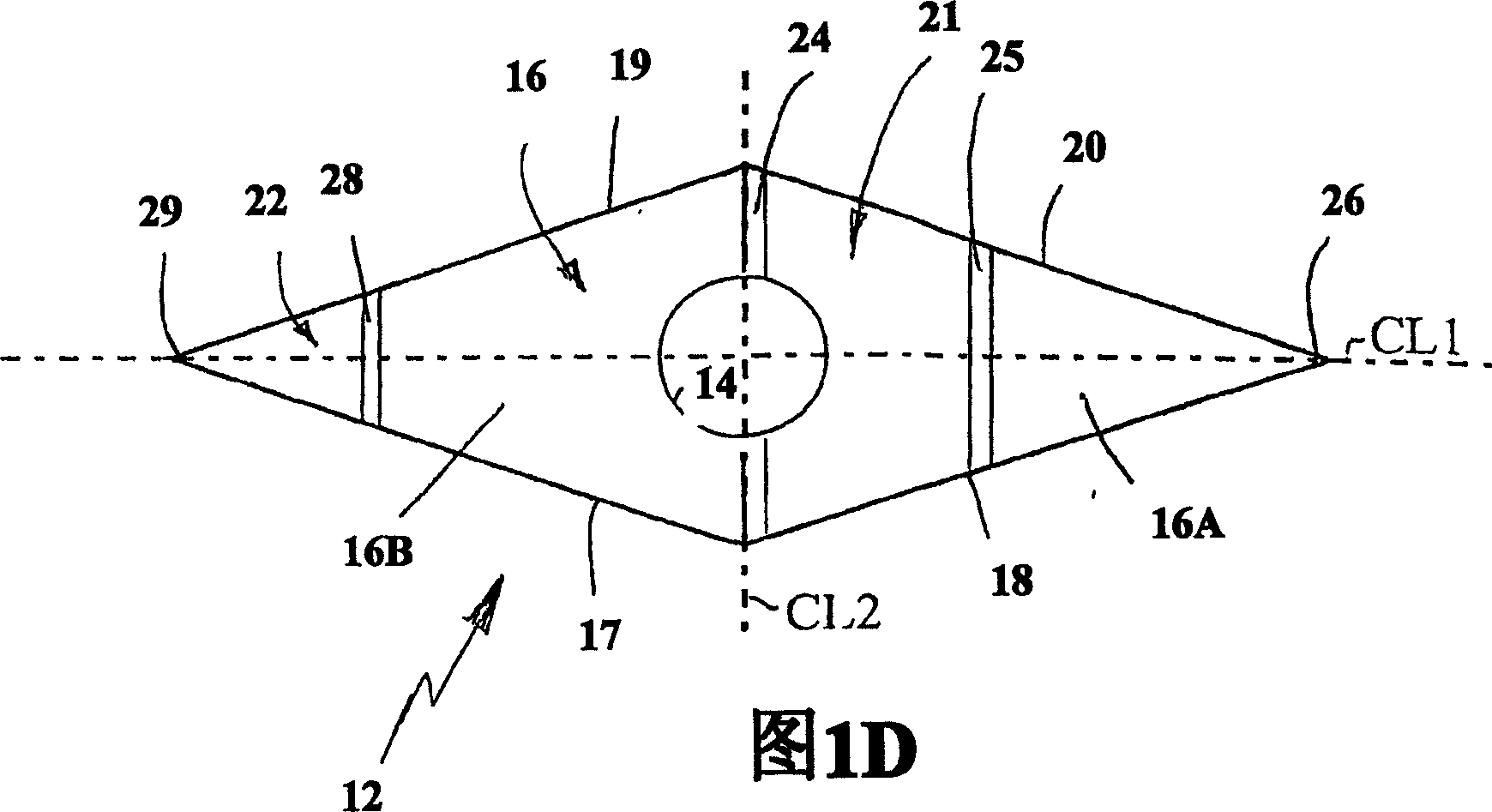

[0018] The spacer 12 has a substantially rhomboid basic shape with an imaginary major axis CL1 and an imaginary minor axis CL2. Here "rhomboid" means an oblique equilateral parallelogram. The axes or diagonals are perpendicular to each other. The major axis corresponds to the angle bisector of acute corners in a rhombus, while the minor axis corresponds to the angle bisec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com