Silicone tube with large inside diameter in lock pin and preparation method

A technology of large inner diameter and silicone tube, which is applied in the field of lock pin large inner diameter silicone tube and its preparation, can solve the problem of low working efficiency of silicone tube and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

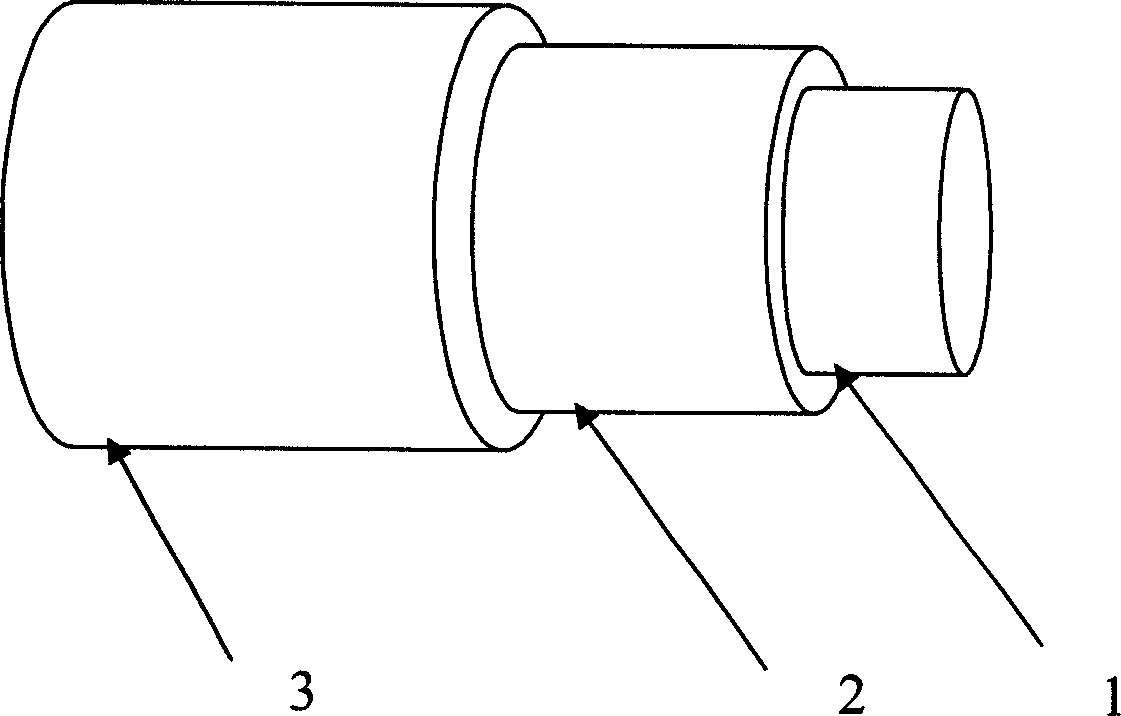

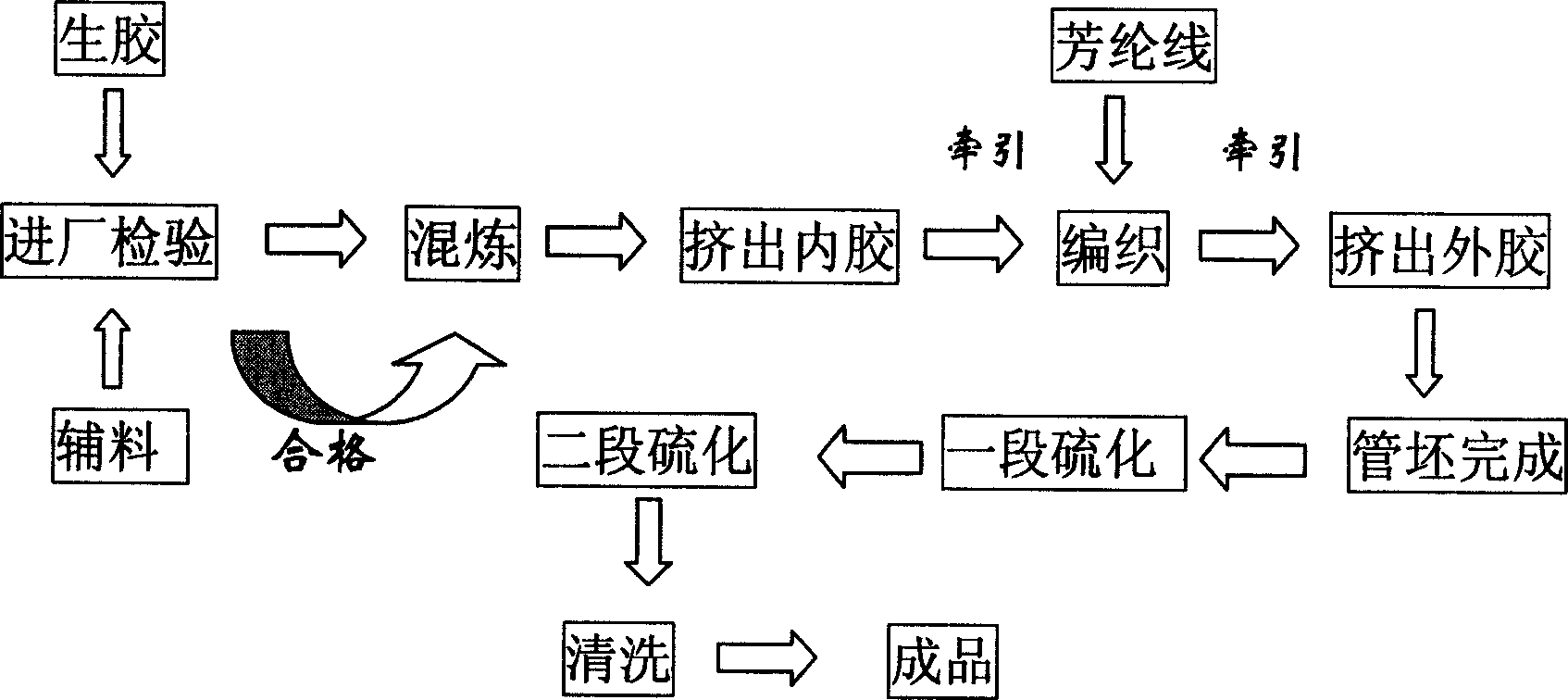

[0021] produce a figure 1 The shown silicone rubber tube with an inner diameter of 50±0.5mm×5±0.5mm×200±3mm, the steps are as follows figure 2 Shown below:

[0022] Firstly, the qualified raw rubber and auxiliary materials are mixed and extruded on the extruder. The extrusion temperature is set at 40±5℃, 30±5℃, 30±5℃, 30±5℃, Each section is at this temperature, and the rubber is re-milled and extruded.

[0023] Reinforcement layer: We decided to choose NORMAX (aramid 2200D), and chose the lock needle structure in knitting. The purpose is to improve the blasting strength of the silicone tube. The speed of the tractor is 3.5±0.5m / min; 10 turns.

[0024] Extrusion cover:

[0025] Select the appropriate needle and mouth shape for extruding the outer rubber, set the extrusion temperature to 40±5°C, 30±5°C, 30±5°C, 30±5°C, and set the temperature for each section of the extruder. The rubber material is re-milled, extruded, and the thickness of the extruded hose is determined a...

Embodiment 2

[0033] Production inner diameter is the silicon rubber tube of 60 ± 1mm * 5 ± 0.5mm * 200 ± 3mm, method step is as shown in embodiment 1, difference is:

[0034] Set the extrusion temperature to 25±5°C, 20±5°C, 20±5°C, 20±5°C, and each section of the extruder is at this temperature, and the rubber is re-milled and extruded.

[0035] The speed of the tractor is 3±0.5m / min; the number of revolutions of the braiding machine is 135±10 revolutions.

[0036] For extruding the needle and mouth shape of the outer rubber, set the extrusion temperature at 25±5°C, 20±5°C, 20±5°C, 20±5°C. Refining, extrusion, and the thickness of the extruded hose are determined according to the wall thickness required by the overall hose.

[0037] One-stage vulcanization: the temperature is 180°C, the time is 5 minutes, and then the secondary vulcanization molding is carried out in an oven, the second-stage vulcanization: the temperature is 200°C, the time is 1H, and then the product can be obtained a...

Embodiment 3

[0039] The production inner diameter is the silicone rubber tube of 30 ± 1mm × 5 ± 0.5mm × 200 ± 3mm, the method steps are as shown in embodiment 1, the difference is:

[0040] Set the extrusion temperature to 45±5°C, 35±5°C, 35±5°C, 35±5°C, and each section of the extruder is at this temperature, and the rubber material is kneaded back and extruded.

[0041] The speed of the tractor is 5±0.5m / min; the number of revolutions of the braiding machine is 165±10 revolutions.

[0042] For extruding the needle and mouth shape of the outer rubber, set the extrusion temperature to 45±5°C, 35±5°C, 35±5°C, 35±5°C. Refining, extrusion, and the thickness of the extruded hose are determined according to the wall thickness required by the overall hose.

[0043] One-stage vulcanization: the temperature is 120°C, the time is 30 minutes, and then the secondary vulcanization molding is carried out in an oven; the second-stage vulcanization: the temperature is 150°C, the time is 4H, and then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com