Camera lenses

A lens group and lens technology, applied in the field of lens groups, can solve the problems of reduced productivity, difficult to correct the assembly position, unfavorable processing, etc., and achieve the effects of easy correction of aberrations, avoidance of defects, and large aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

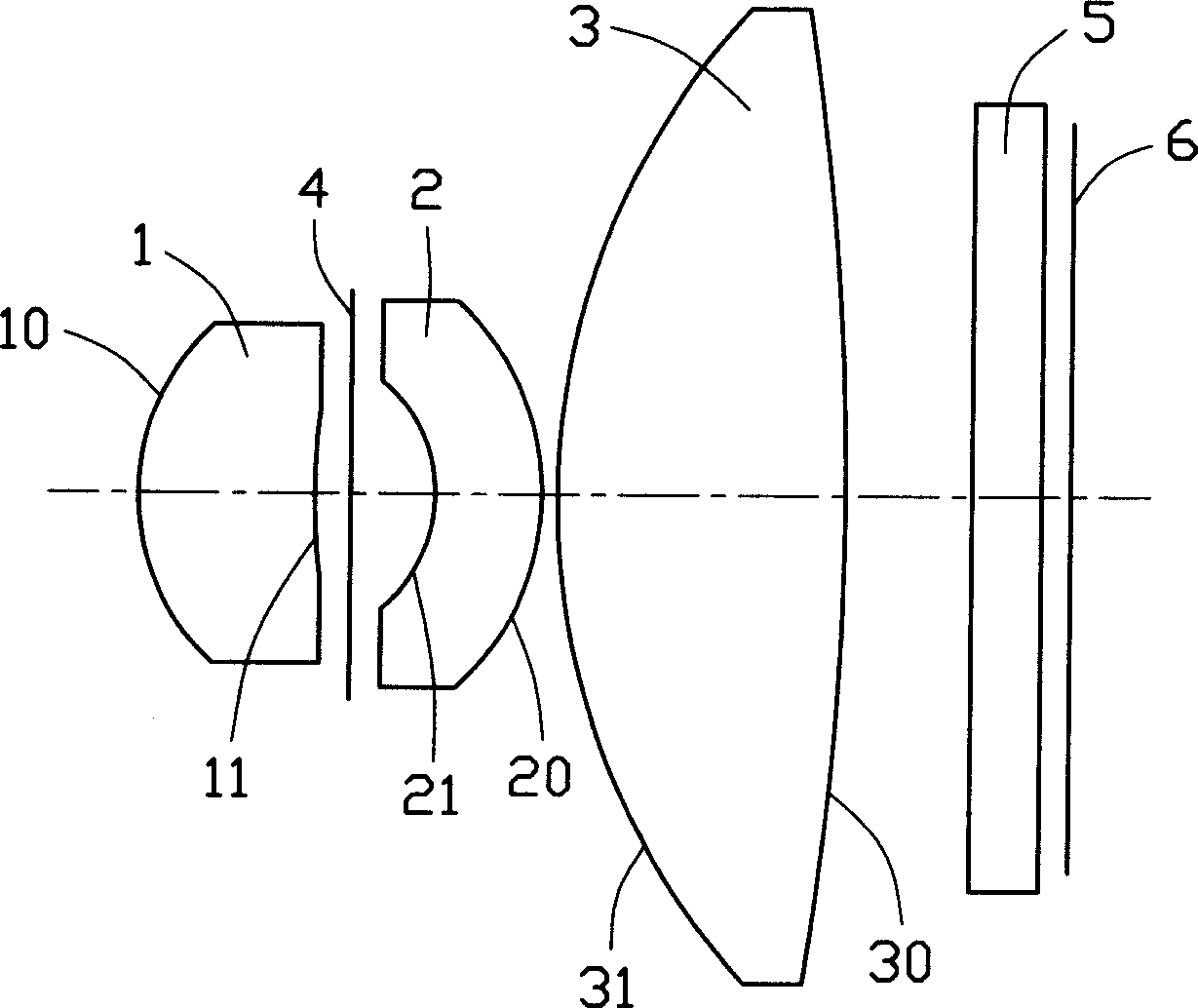

[0034] Please refer to figure 2 The composition structure of the shown lens group of the present invention includes an aperture 4 and an optical group, wherein the optical group is mainly composed of three lenses, and the order from the object side to the image side is as follows: the first lens 1 is a positive lens, which is The crescent-shaped plastic lens is located at the beginning of the lens, and its convex surface 10 faces the object side; the second lens 2 is a negative lens, which is also a crescent-shaped plastic lens and is arranged symmetrically with the first lens 1, that is, the second lens 2 The convex surface 20 of lens 2 is towards the image side (imaging surface 6), and its concave surface 21 is then set opposite to the concave surface 11 of first lens 1; The radius of curvature of the surface 30 near the image side of 3 is greater than the radius of curvature of the surface 31 near the object side; the aperture 4 is located between the first lens 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com