Welding joint of fuel tank

A technology for welding joints and fuel tanks, which is applied to non-removable pipe connections, pipes/pipe joints/pipes, passing components, etc. The effect of resistance to fuel penetration and excellent weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

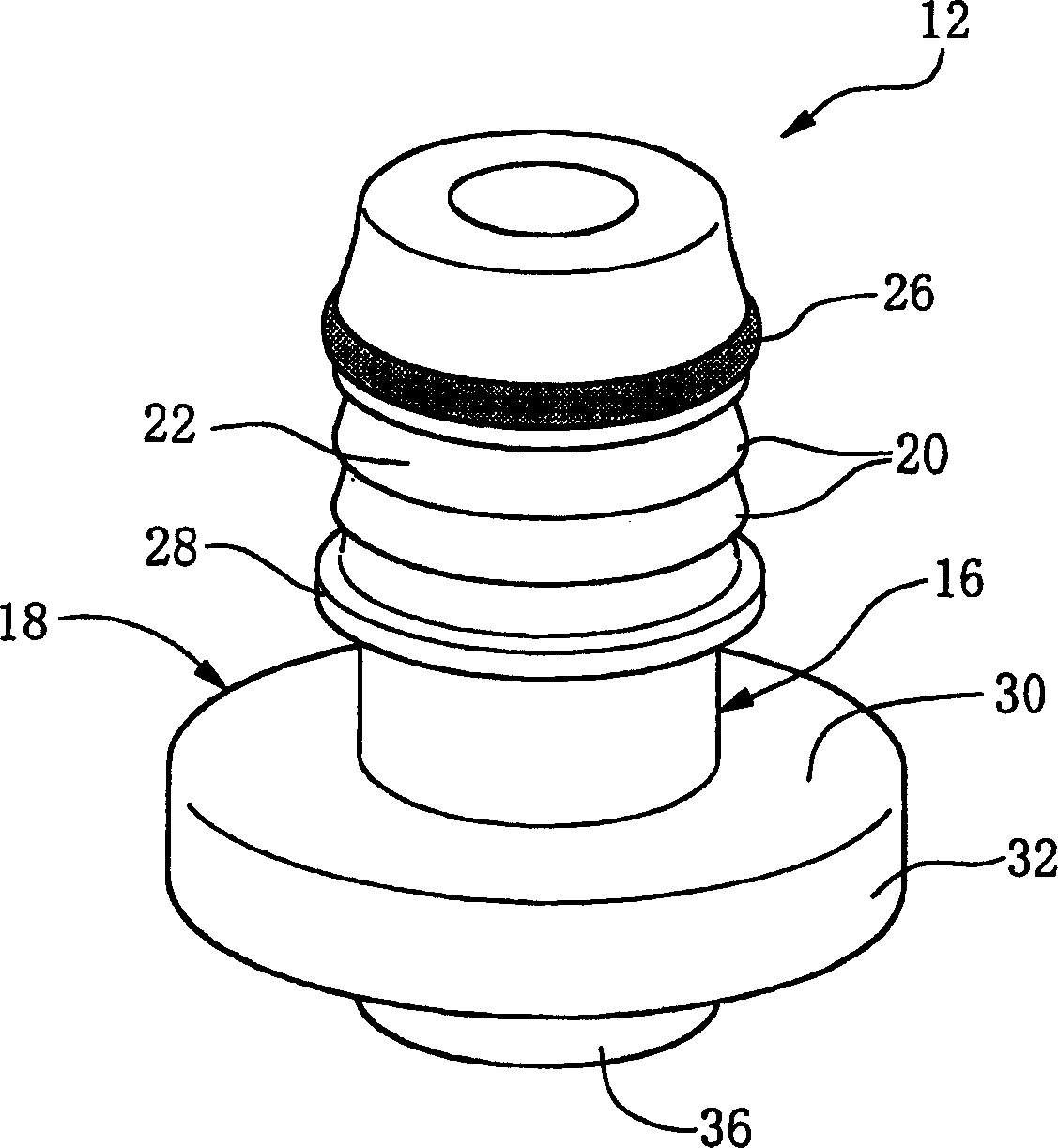

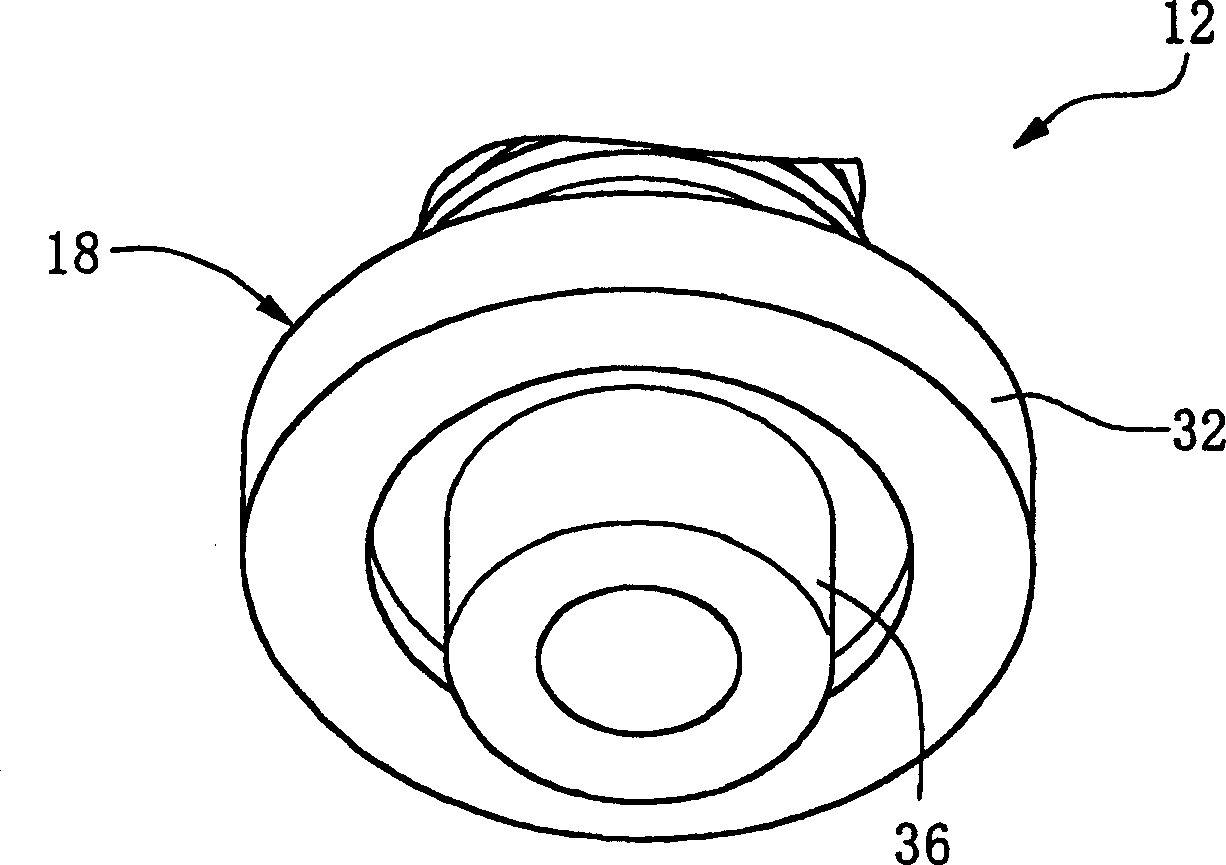

[0083] Now, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

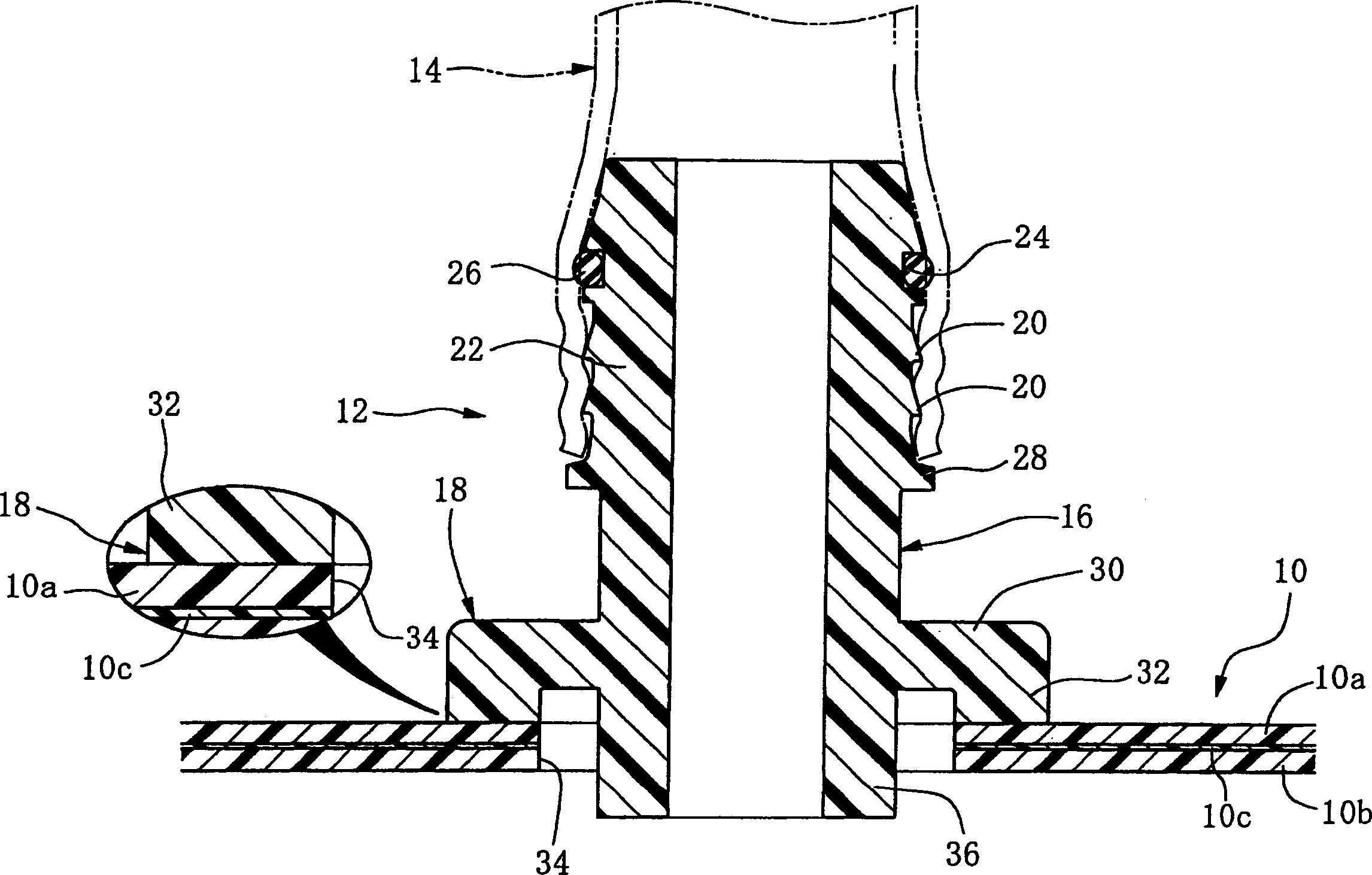

[0084] see figure 1 and 3 , Reference numeral 10 denotes a resin fuel tank. Here, the fuel tank 10 is formed in a stacked structure consisting of an outer layer 10a, an inner layer 10b made of HDPE resin, and a thin barrier layer (middle layer) 10c.

[0085] Here, the barrier layer 10c is made by using EVOH resin excellent in fuel permeation resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com