Half bepowdering method for fluorescent lamp tube

A technology for fluorescent tubes and fluorescent powder, which is applied in the processing of fluorescent tubes and half-coating of fluorescent tubes. It can solve the problems of not considering the length and shape of the tubes, and can not be used, so as to save fluorescent powder, improve utilization rate, spectrally rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

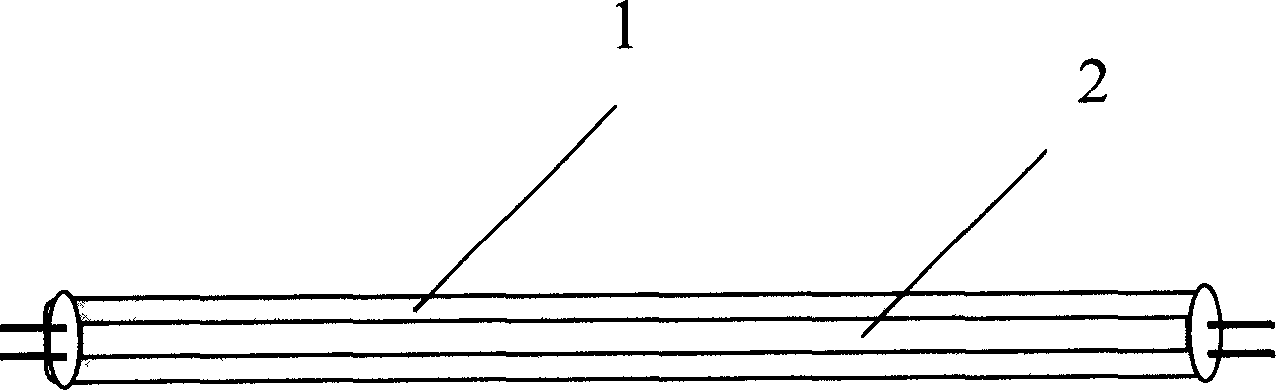

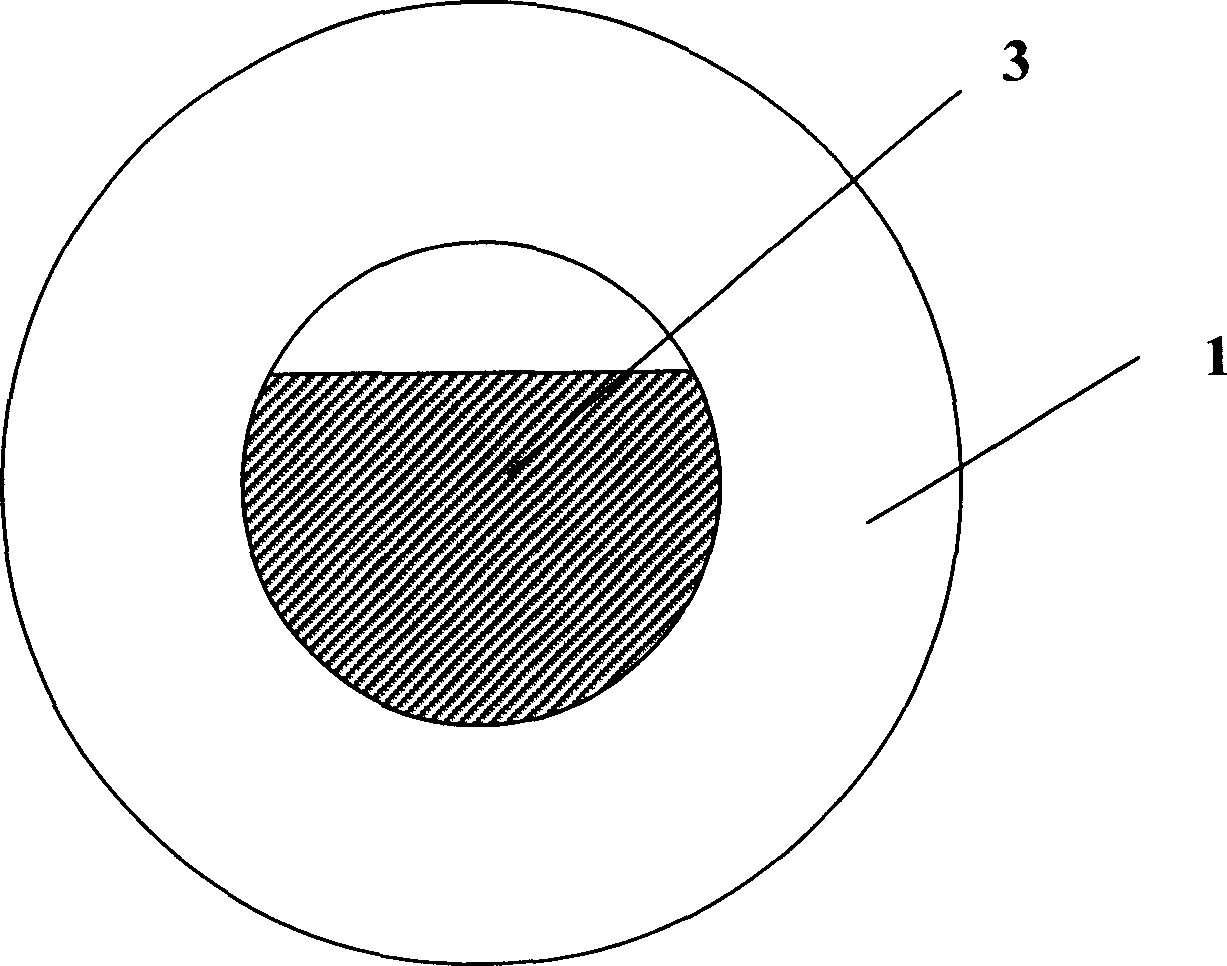

[0014] Such as figure 1 and figure 2 As shown, a method for semi-powdering a fluorescent lamp tube of the present invention includes the first step of cleaning and drying the glass tube 1, the second step of coating the glass tube 1 wall with an aluminum oxide powder protective film and drying it, The third step of coating the inner wall of the glass tube 1 with phosphor powder and the fourth step of baking the glass tube 1 coated with phosphor powder, wherein, in the first step of coating the inner wall of the glass tube 1 with phosphor powder In the third step, the phosphor powder is coated on part of the inner wall of the glass tube 1, and a light-transmitting area 2 is reserved on the remaining part of the inner wall of the glass tube 1, and the light-transmitting area 2 is isolated from the phosphor powder.

[0015] Further, the length direction of the light-transmitting region 2 is parallel to the axial direction of the glass tube 1, and the width of the curved surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com