Multi-section membrane absorption flue gas desulfurization and decarburization method and device thereof

A membrane absorption and flue gas technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of poor selective absorption effect, low reusability of absorption liquid, low product utilization rate, etc. The effect of dust pollution self-cleaning ability, low energy consumption required for desorption, and less thermally stable salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

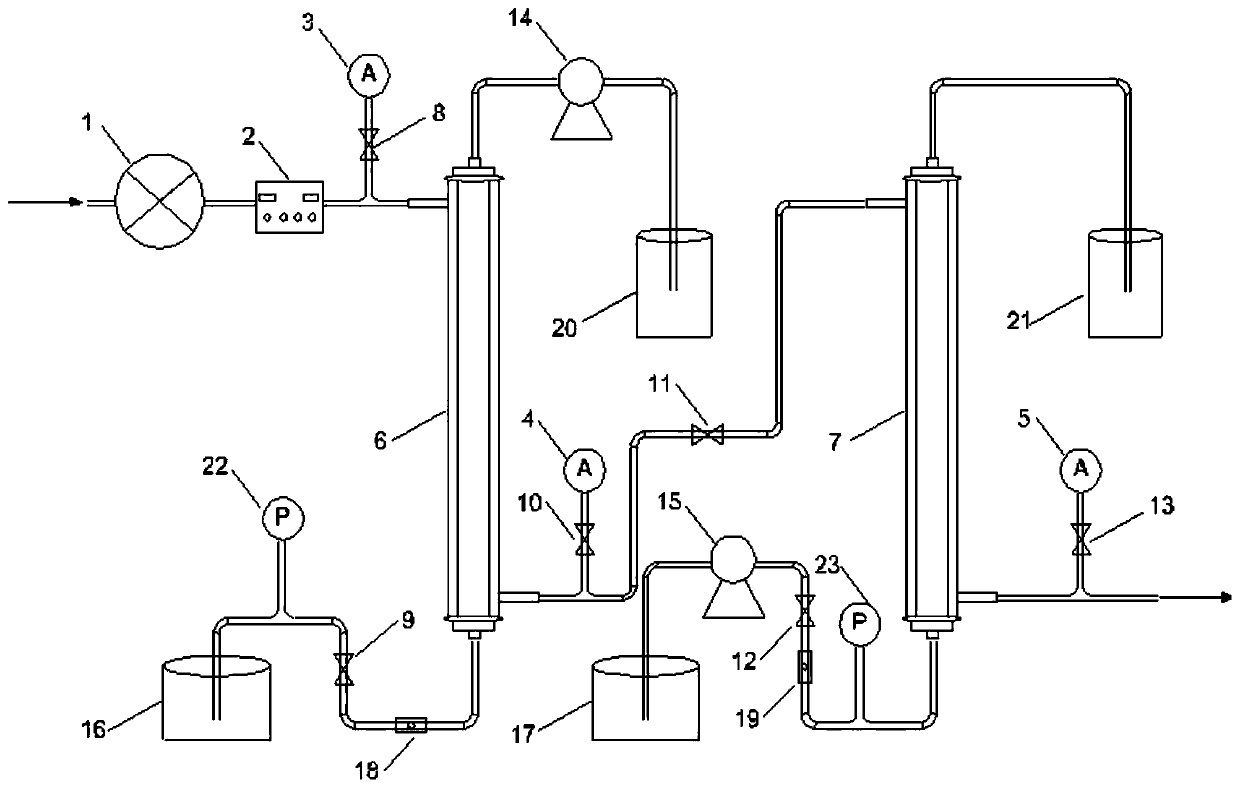

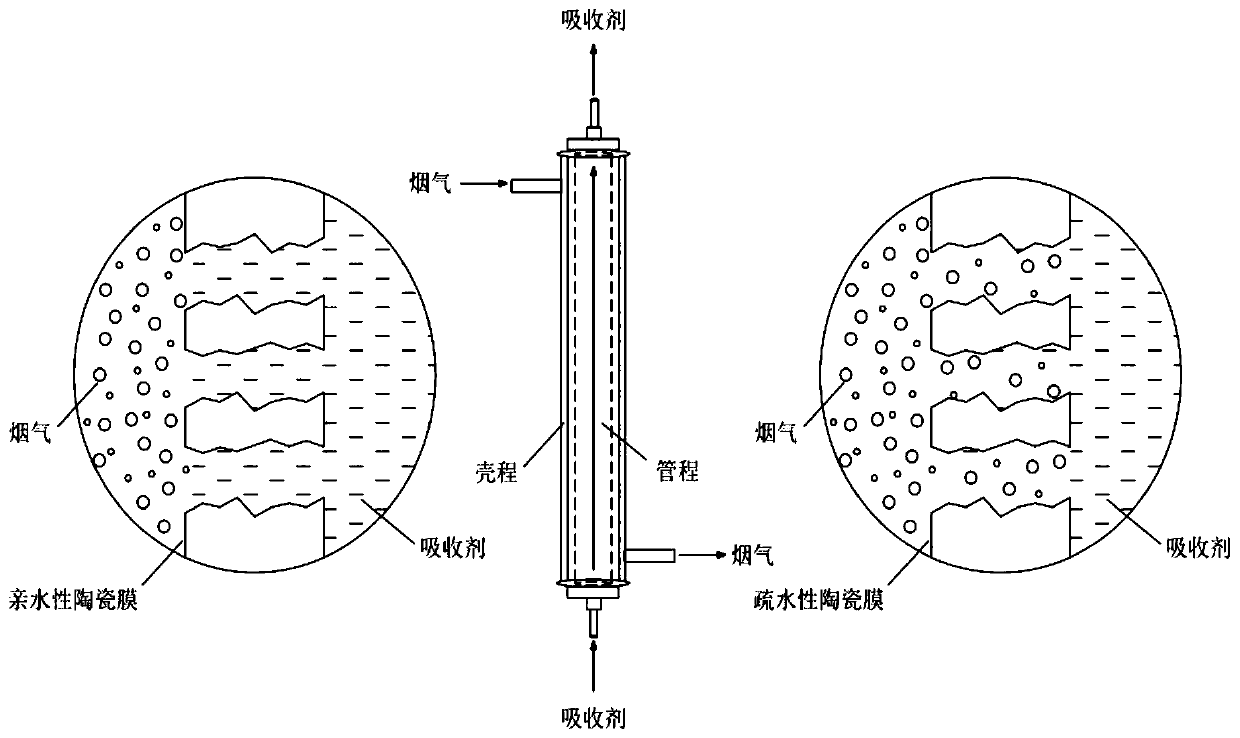

[0063] use as figure 1 The flue gas combined desulfurization and decarbonization device and its process shown are used to treat the tail gas of a Claus process, and the tail gas flow rate is 10 m 3 / h, flue gas temperature is 20℃, SO 2 The volume fraction is 100ppm, CO 2 The volume fraction is 1 % (volume fraction). After dedusting by the flue gas pretreatment device, the flue gas flow control device enters the hydrophilic ceramic membrane contactor (membrane aperture 0.05 μm, contact angle 10°); the absorbent in the desulfurization section is 5wt% methyldiethanolamine, absorbing Agent flow rate 10 m 3 / h, after the desulfurization section treats tail gas SO 2 content dropped to 5ppm, CO 2 The content is about 1 % (volume fraction), and the desulfurization section has an effect on SO 2 The removal rate can reach more than 99%, and the CO 2 The removal rate is less than 1%; then enter the hydrophobic ceramic membrane contactor (membrane aperture 0.05μm, contact angle 90...

Embodiment 2

[0065] use as figure 1The flue gas combined desulfurization and decarbonization device and its process shown are used to treat the tail gas of a Claus process, and the tail gas flow rate is 200 m 3 / h, flue gas temperature is 100℃, SO 2 The volume fraction is 1000ppm, CO 2 The volume fraction is 10 % (volume fraction). After the dust is removed by the flue gas pretreatment device, the flue gas flow control device enters the hydrophilic ceramic membrane contactor (the membrane aperture is 1 μm, the contact angle is 50°); the absorbent in the desulfurization section is 15wt% sodium hydroxide solution, and the absorbent Flow 100m 3 / h, after the desulfurization section treats tail gas SO 2 content dropped to 8ppm, CO 2 The content is about 9.9% (volume fraction), and the SO 2 The removal rate can reach more than 99%, and the CO 2 The removal rate is 1%; then enter the hydrophobic ceramic membrane contactor (membrane pore size 3μm, contact angle 170°), the decarburization ...

Embodiment 3

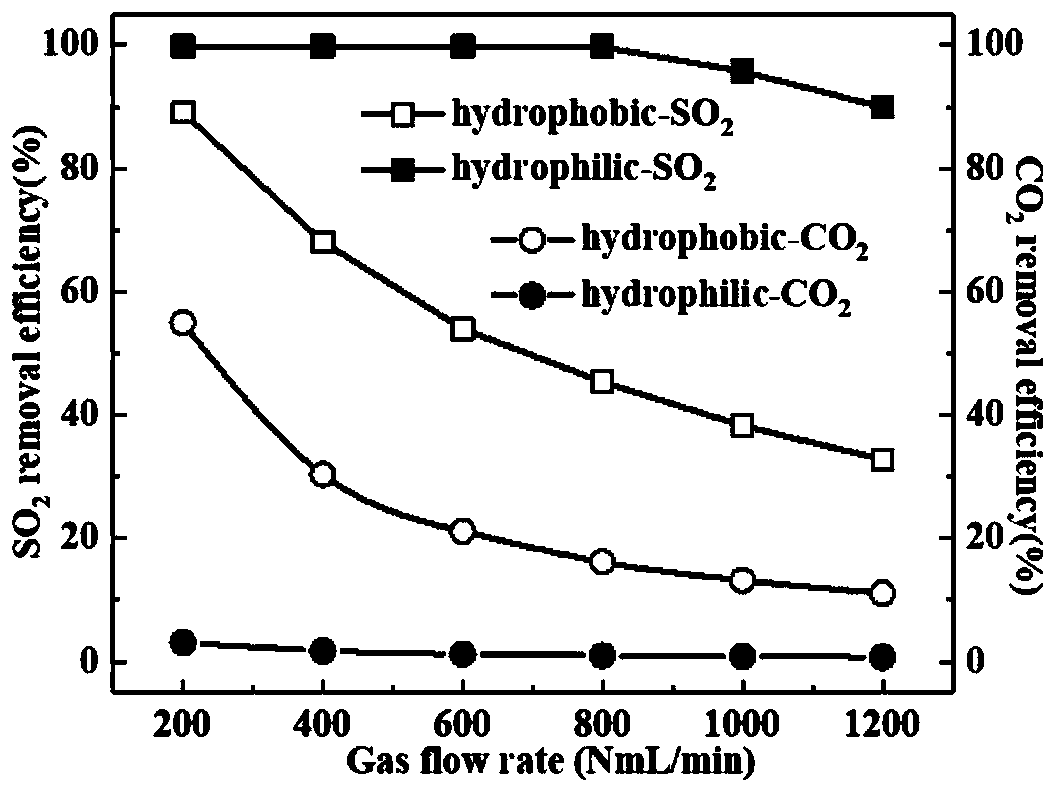

[0070] In this example, the influence of different gas flow conditions on the absorption process of hydrophilic membranes and hydrophobic membranes is investigated. The membrane pore size of the hydrophilic ceramic membrane contactor is 0.05 μm, and the contact angle is 10°; the hydrophobic ceramic membrane contactor The membrane pore size is 0.05 μm, the contact angle is 140°, the gas temperature is 20°C, and the absorbent flow rate is 10 m 3 / h. 0.4mol / L NaOH solution was used as absorbent in the hydrophilic membrane and hydrophobic membrane respectively, the SO in the gas 2 The concentration is 1000 ppm (molar concentration), CO 2 The concentration was 10 % (molar concentration), and the effect of gas flow rate on the selectivity factor was studied. It was found that compared with the hydrophobic membrane, the SO in the hydrophilic membrane 2 With higher removal efficiency and absorption flux, CO 2 have lower removal efficiencies and absorption fluxes (eg image 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com