Method for preparing astringency-removed persimmon instant powder through spray freeze-drying method

A spray freeze-drying and persimmon technology, which is applied in the field of food and food processing, can solve the problems of single form, short storage time, and poor taste, and achieve the effects of easy operation, industrial production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

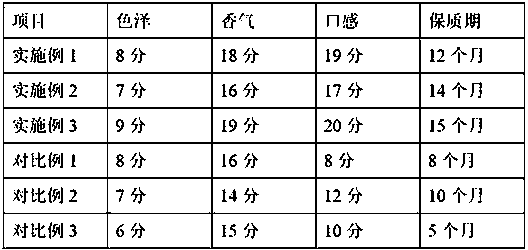

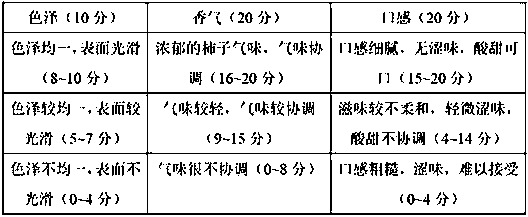

Examples

Embodiment 1

[0032] A method for preparing deastringent persimmon instant powder by spray freeze-drying method, comprising the following steps:

[0033] (1) Deastringency: Soak persimmons in the treatment solution at 35°C, add 5 drops of hydrochloric acid dropwise, and soak for 18 hours; the treatment solution is: 40 parts of illite, 30 parts of stable chlorine dioxide solution, calcium citrate 5 parts, 100 parts of water;

[0034] (2) Peeling and removing the core: remove the persimmon skin from the persimmon in step (1), and remove the fruit pedicle and persimmon seed;

[0035] (3) Wet ultrafine pulverization: Add 1kg of peeled and pitted persimmon meat to 0.1kg of ice water, then add 11g of calcium phosphate, 385g of fermented pomelo peel, and wet pulverize to 80 mesh with a cutting type wet ultrafine pulverizer;

[0036] (4) Tempering: Grind 4 times by colloid mill, homogenize 3 times by high-pressure homogenizer, and filter 5 times with non-woven fabric;

[0037] (5) Spray freeze-dr...

Embodiment 2

[0040] A method for preparing deastringent persimmon instant powder by spray freeze-drying method, comprising the following steps:

[0041] (1) Deastringency: Soak persimmons in the treatment solution at 40°C, add 10 drops of hydrochloric acid dropwise, and soak for 16 hours; the treatment solution is: 50 parts of illite, 20 parts of stable chlorine dioxide solution, calcium citrate 1 part, 100 parts of water;

[0042] (2) Peeling and removing the core: remove the persimmon skin from the persimmon in step (1), and remove the fruit pedicle and persimmon seed;

[0043] (3) Wet ultrafine grinding: Add 1 kg of peeled and de-pitted persimmon meat to 0.3 kg of ice water, then add 65 g of calcium phosphate and 325 g of fermented pomelo peel, and wet grind to 100 mesh;

[0044] (4) Tempering: Grind 5 times with a colloid mill, homogenize 2 times with a high-pressure homogenizer, and filter 3 times with a non-woven fabric;

[0045] (5) Spray freeze-drying: adjust the parameters of th...

Embodiment 3

[0048] A method for preparing deastringent persimmon instant powder by spray freeze-drying method, comprising the following steps:

[0049] (1) Deastringency: Soak persimmons in the treatment solution at 38°C, add 5 drops of hydrochloric acid dropwise, and soak for 17 hours; the treatment solution is: 45 parts of illite, 25 parts of stable chlorine dioxide solution, calcium citrate 3 parts, 100 parts of water;

[0050] (2) Peeling and removing the core: remove the persimmon skin from the persimmon in step (1), and remove the fruit pedicle and persimmon seed;

[0051] (3) Wet ultrafine grinding: Add 1 kg of peeled and de-pitted persimmon meat to 0.2 kg of ice water, then add 36 g of calcium phosphate, 360 g of fermented pomelo peel, and wet grind to 100 mesh;

[0052] (4) Tempering: Grind 5 times with a colloid mill, homogenize 3 times with a high-pressure homogenizer, and filter 5 times with a non-woven fabric;

[0053] (5) Spray freeze-drying: adjust the parameters of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com