Insulin pump

A technology for syringes and insulin, applied in the directions of syringes, auto-injectors, hypodermic injection devices, etc., can solve problems such as damage to the durability of the rotating shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now, the present invention will be explained in detail in conjunction with preferred embodiments with reference to the accompanying drawings.

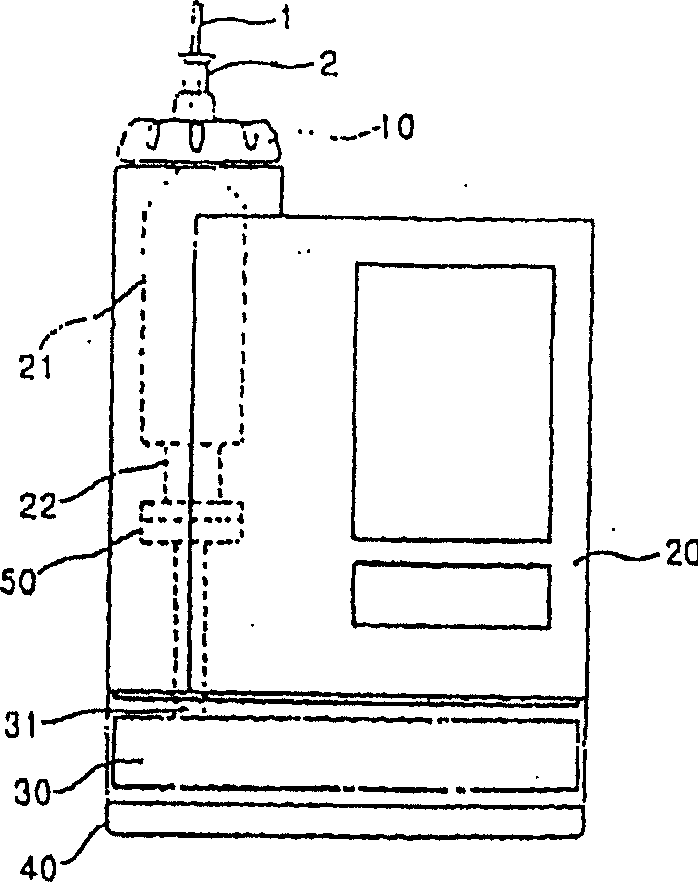

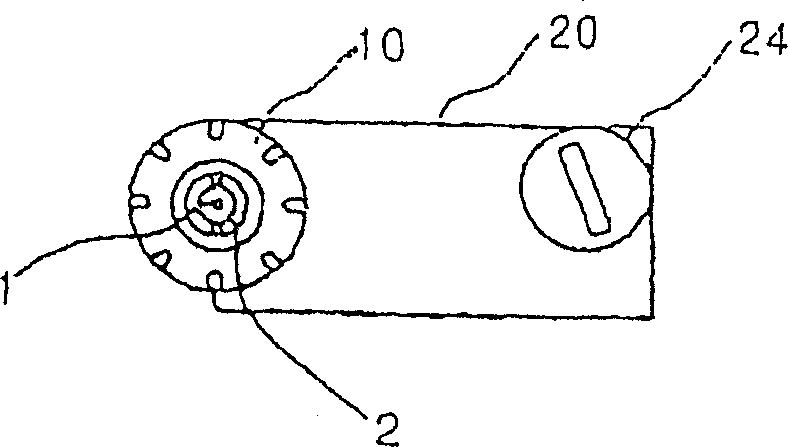

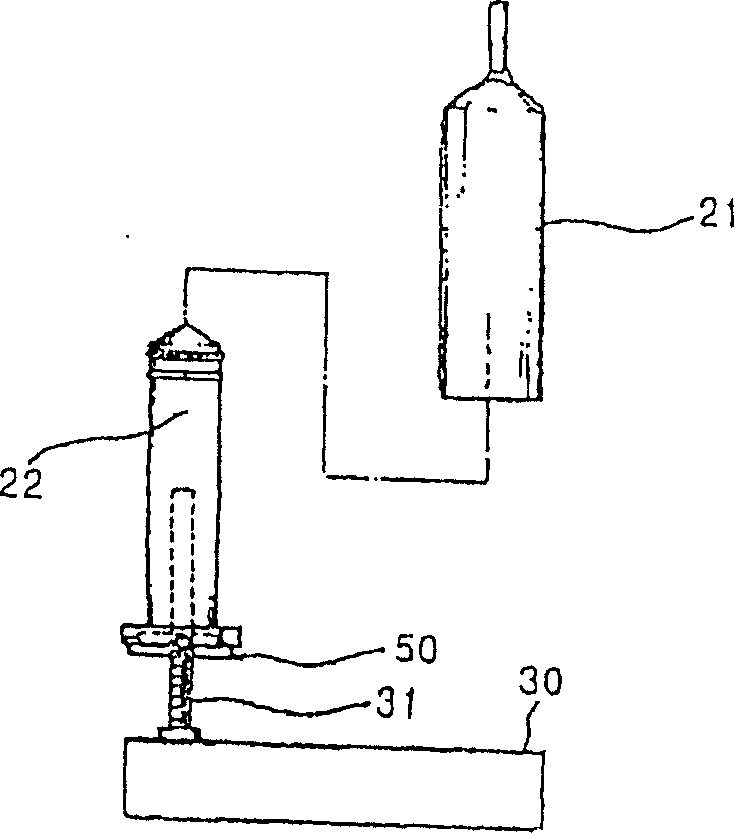

[0021] Figure 5 is a schematic perspective view of an automatic insulin injector according to a preferred embodiment of the present invention, Figure 6 is an exploded perspective view of the automatic insulin injector of the present invention. Such as Figure 5 and 6 As shown, the automatic insulin injector according to the present invention has a syringe 120 housed in a small box-like housing 100 . For this purpose, the housing 100 has a cylindrical syringe receiving space 102 formed longitudinally at one side inside the housing. Housing 100 has a battery compartment (not shown) in place to provide power to various electronic components. Reference numeral 106 denotes a battery cover for confining a battery (not shown) in the battery space. The housing 100 also includes a liquid crystal display (LCD) window 110 installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com