Disease-resistant nutrient solution for tree growth

A nutrient solution and tree technology, which is applied in the field of tree growth and disease-resistant nutrient solution and plant biological liquid fertilizer, can solve the problems of not very obvious results, increased investment, unreasonable ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Get 800 milliliters of tap water and heat it to 60°C, pour it into a plastic container, then pour 8 grams of EDTA chelating agent into the water and stir until completely dissolved, then add 100 grams of FeSO 4 ·7H 2 O is poured into and continues stirring until completely dissolved, and then 28 grams of ZnSO 4 ·7H 2 O is poured into and continues stirring until completely dissolved, and then 18 grams of MnSO 4 4H 2 Pour in O and continue stirring until completely dissolved, then pour in 30 g of H 3 BO 3 Pour and continue to stir until completely dissolved, then add 4 g of MgSO 4 ·7H 2 Pour into O and continue to stir until it is completely dissolved, and then add 12 grams of GaCl 2 2H 2 Pour in O and continue to stir until it is completely dissolved, and finally fully stir for 30 minutes, let it stand for 3 hours, then filter it with fine gauze and pack it.

Embodiment 2

[0015] Example 2: Get 850 milliliters of tap water heated to 60 degrees and pour into a plastic container, then pour 7 grams of citric acid into the water and stir until completely dissolved, then add 70 grams of FeSO 4 ·7H 2 O is poured into and continues stirring until completely dissolved, and then 15 grams of ZnSO 4 ·7H 2 O poured into and continued stirring until completely dissolved, and then 16 grams of MnSO 4 4H 2 O was poured into and continued to stir until completely dissolved, then poured 28 grams of H 3 BO 3 Pour and continue to stir until completely dissolved, then add 3 g of MgSO 4 ·7H 2 O is poured into and continues stirring until completely dissolved, and then 11 grams of GaCl 2 2H 2 Pour in O and continue to stir until it is completely dissolved, and finally fully stir for 30 minutes, let it stand for 3 hours, then filter it with fine gauze and pack it.

Embodiment 3

[0016] Embodiment 3: get 900 milliliters of tap water and heat to 60 degrees and pour into a plastic container, then pour 4 grams of tartaric acid into water and stir until fully dissolved, then add 40 grams of FeSO 4 ·7H 2 O is poured into and continues stirring until completely dissolved, and then 15 grams of ZnSO 4 ·7H 2 O was poured into and continued to stir until it was completely dissolved, and then 10 grams of MnSO 4 4H 2 Pour in O and continue stirring until completely dissolved, then pour in 25 g of H 3 BO 3 Pour in and continue stirring until completely dissolved, then add 2 g of MgSO 4 ·7H 2 O is poured into and continues stirring until completely dissolved, and then 4 grams of GaCl 2 2H 2 Pour in O and continue to stir until it is completely dissolved, and finally fully stir for 30 minutes, let it stand for 3 hours, then filter it with fine gauze and pack it.

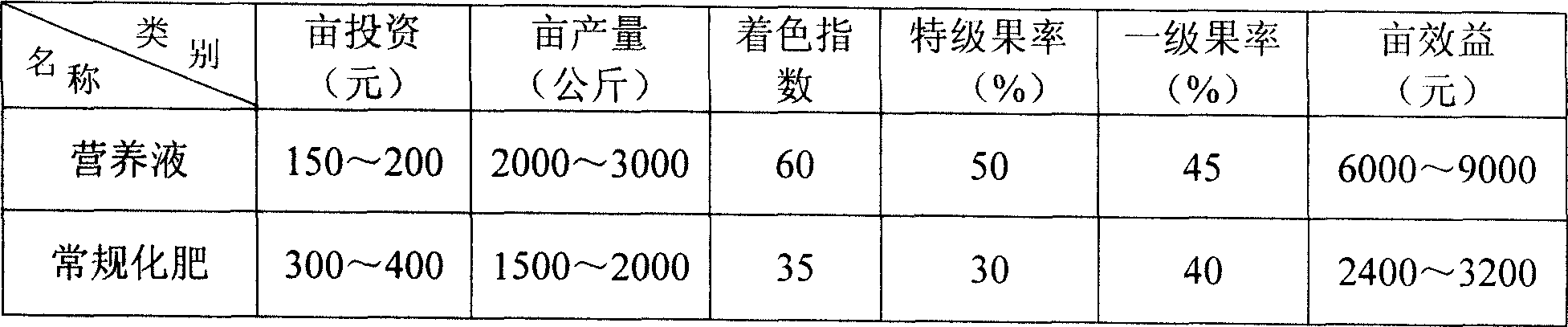

[0017] Above-mentioned embodiment can enumerate multiple, proves through the inventor's test, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com