Laser direct writing anti-counterfeit label

A technology of anti-counterfeiting marking and laser direct writing, which is applied in the field of anti-counterfeiting marking, can solve the problems of losing anti-counterfeiting characteristics, achieve the effect of increasing anti-counterfeiting reliability, ensuring anti-counterfeiting reliability, and important application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

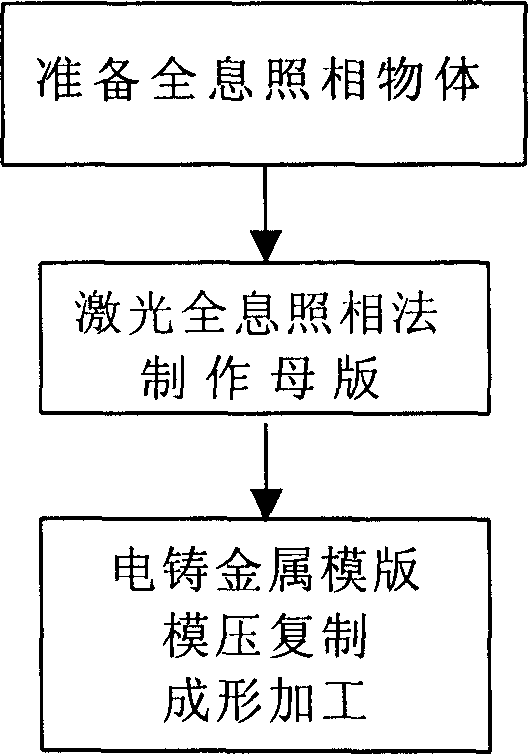

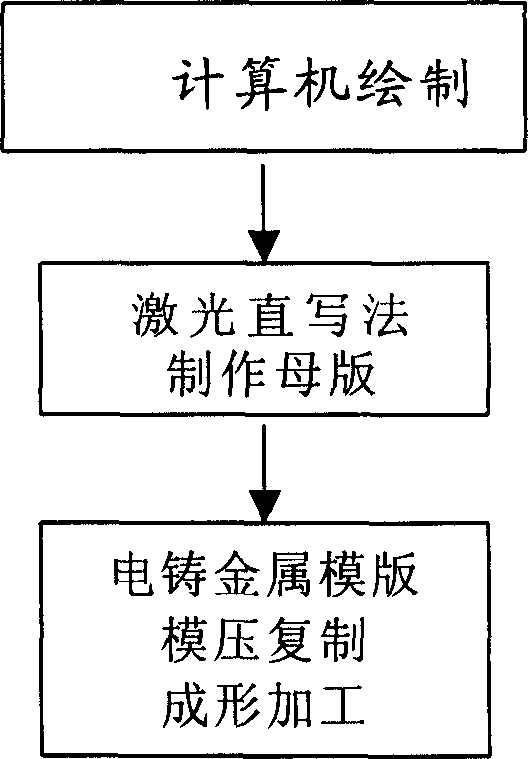

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Micro grating structure pattern and text anti-counterfeiting mark

[0018] A micro-grid structure arranged with micron-scale or thinner lines forms a macroscopic pattern and text strokes with a rainbow effect. In the same logo pattern, the period and direction of the grating stripes of each local pattern or character stroke can be selected arbitrarily, and the period encryption and direction encryption of the grating stripes can be performed.

[0019] In this embodiment, words such as "ZKYGDS Institute of Optoelectronic Technology, Chinese Academy of Sciences" are first drawn with a computer, and they are arranged in a circular shape, and a five-pointed star is drawn in the center of the circle. , the grating lines are also formed with a pitch of 1.5 μm and are inclined at 30°. Here, the width and inclination angle of the grating lines constituting the characters and patterns can be selected arbitrarily for encryption. Then, copy the graphic files drawn ...

Embodiment 2

[0020] Embodiment 2: Anti-counterfeiting mark of microtext

[0021] The character height of the Chinese microtext produced by the present invention can be as small as 20 microns, and the character height of English letters and Arabic numerals can be as small as 10 microns, which cannot be achieved by other printing technologies.

[0022] In this embodiment, at first, the computer is used to draw the characters such as "Institute of Optoelectronic Technology, Chinese Academy of Sciences" with a character height of 16 microns and the characters "GDShds507" with a character height of 8 microns, and then the graphic files drawn by the computer Copy it into the laser direct writing system, use the special process of the laser direct writing system to make a photolithography mask to expose the photoresist film layer on the substrate, and transfer the designed microtext graphics to the photoresist precisely , and then develop the exposed photoresist film layer on the substrate with a...

Embodiment 3

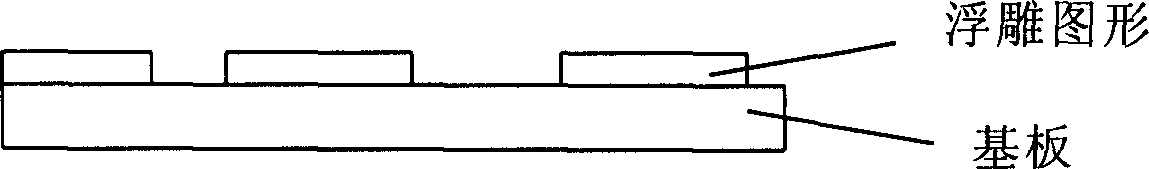

[0023] Embodiment 3: Anti-counterfeiting mark of filling pattern

[0024] Fill large patterns or text strokes with encoded numbers, encrypted ASCII characters, special patterns, etc. Numbers, characters, content, size and direction of special patterns used for filling can be used for encryption.

[0025] In this embodiment, a computer is first used to draw a Chinese character "electricity" with a character height of 2 mm and a Chinese character "Suo" with a character height of 1.2 mm. Here, the character height size of the text can also be used for encryption. Each stroke of the character "electricity" is filled with the character string "2004" with a character height of 12 microns at an angle of 45°. 300° filling composition. Here, the content, size, inclination angle, etc. of the padding string can be used for encryption. Then, the filling pattern file drawn by the computer is copied into the laser direct writing system, and the photoresist film layer on the substrate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com