Organophosphate polypropylene nucleation agent and its preparation method

A technology of polypropylene nucleating agent and organic phosphate ester is applied in the field of polypropylene nucleating agent and its preparation, which can solve the problems of environmental pollution, complicated operation, increase of manufacturing cost, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0028] Example 1-3 Preparation of the nucleating agent of the present invention

Embodiment 1

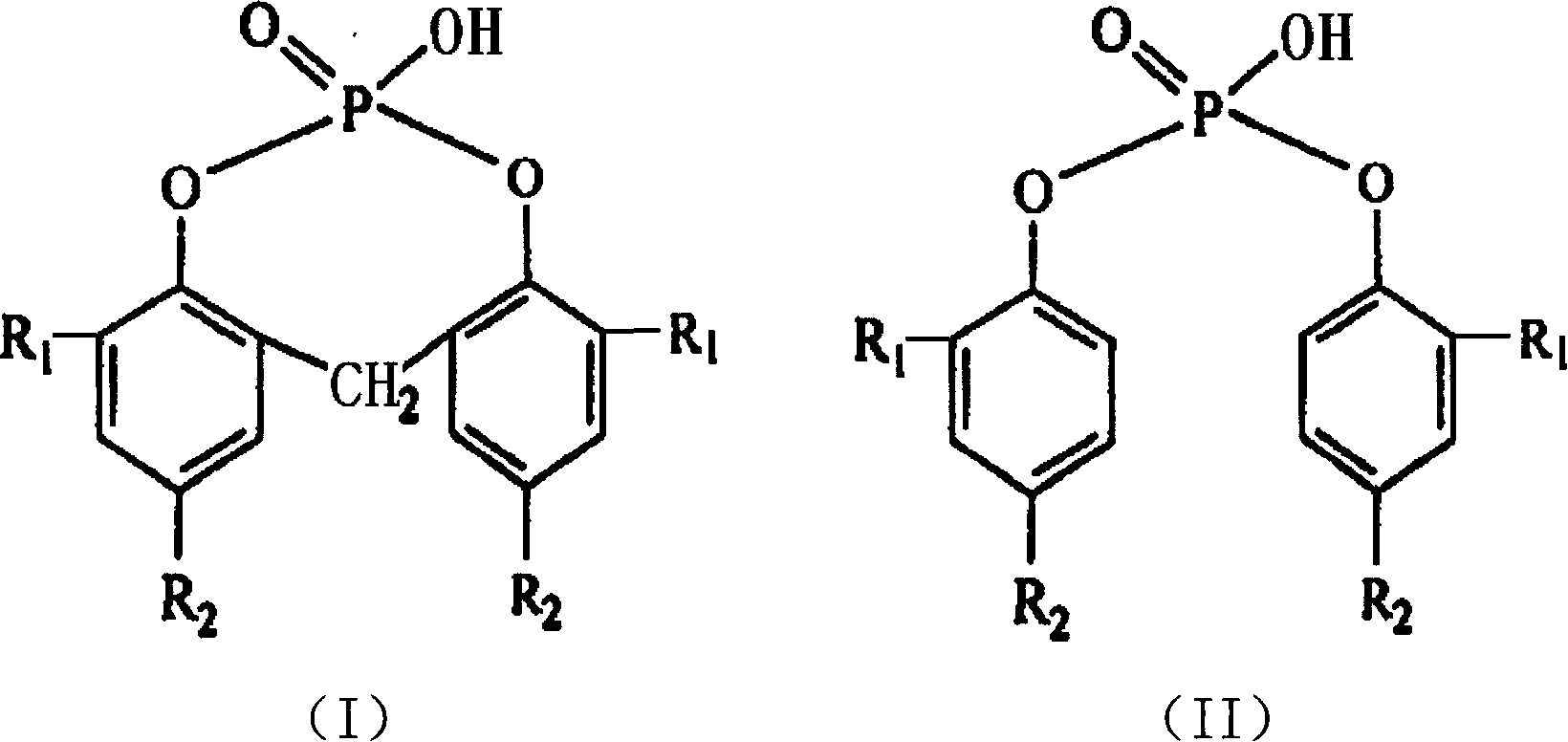

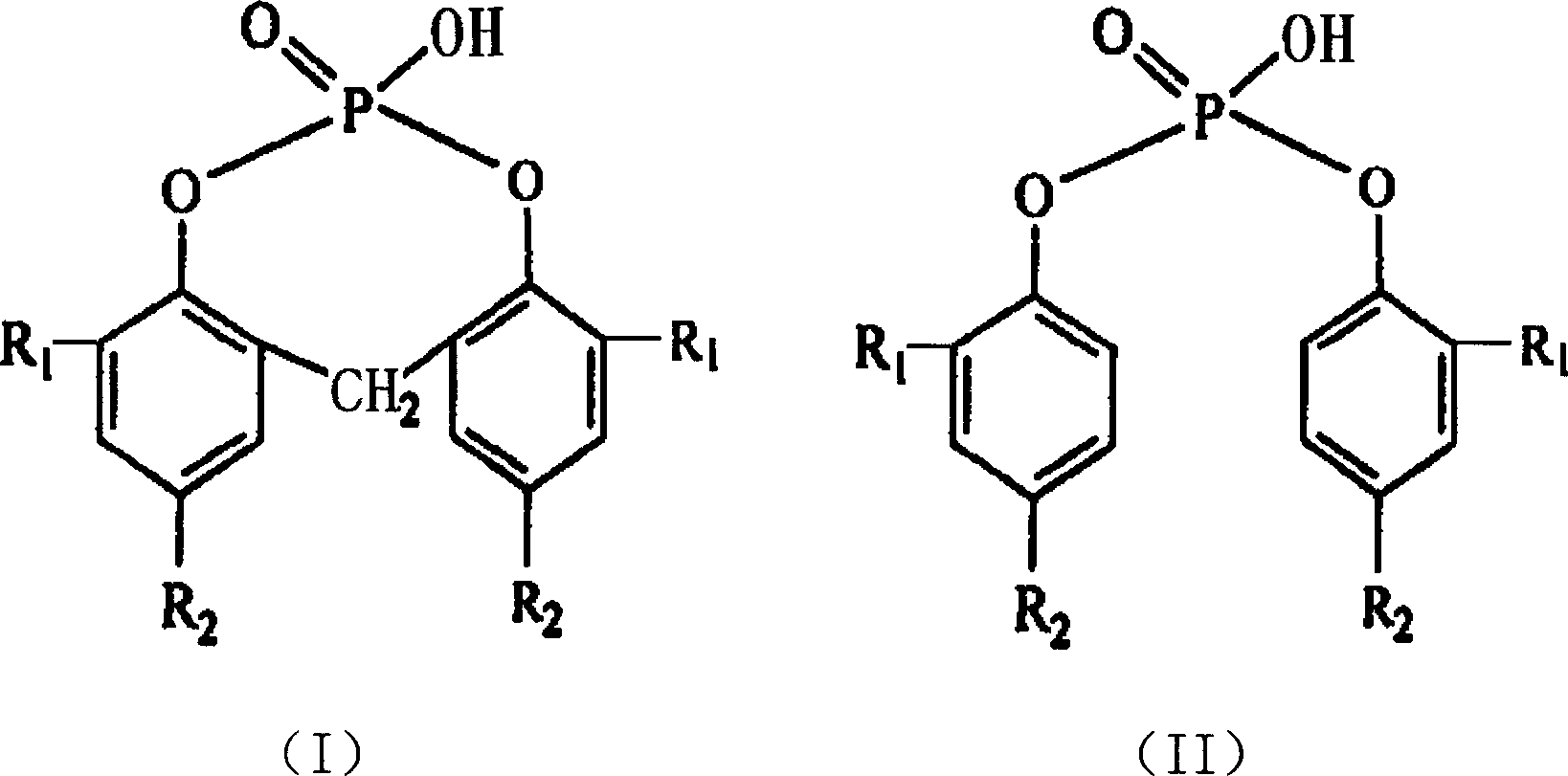

[0030] Add 53.88 g of bis(2,4-di-tert-butylphenoxy)phosphoric acid to the dry mixing mixer, whose structural formula is shown in (II), R 1 , R 2 is tert-butyl. Under stirring, 1.8 grams of catalyst urea was dissolved in 3 grams of water, and the aqueous solution of urea, 2.5 grams of acetone, and 36.2 grams of isobutanol were sprayed with a sprayer, and then mixed at room temperature for 1 hour, and then the temperature was raised to 40 ~50 °C for 1.5 hours, the moisture content of the material measured by a rapid humidity tester is 13±2%, then the temperature is raised to 135 °C, stirring is continued for 2.5 hours, then dried, and pulverized to obtain bis(2,4- Di-tert-butylphenoxy) tert-butyl phosphate, melting point greater than 270°C.

Embodiment 2

[0032] 70.2 g of 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)phosphoric acid was added to the dry mixing mixer, the structural formula of which is shown in (I), R 1 , R 2 is tert-butyl. Under stirring, 1.8 grams of catalyst urea was dissolved in 3 grams of water, and the aqueous solution of urea, 2.5 grams of acetone, and 37.8 grams of isobutanol were sprayed with a sprayer, and then mixed at room temperature for 1 hour, and then the temperature was raised to 40~ Keep at 50°C for 1.5 hours, measure the moisture content of the material with a rapid humidity meter to be 13±2%, then raise the temperature to 138°C, continue stirring for 2.5 hours, then dry and pulverize to obtain 2,2′-methylene Base-bis(4,6-di-tert-butylphenoxy) tert-butyl phosphate, melting point greater than 270°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com