Energy-saving hot blast valve using little water

A hot blast valve and micro water technology, applied in blast furnace details, blast furnace parts, furnaces, etc., to reduce air temperature loss, obvious energy saving effect, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be described below with reference to the accompanying drawings.

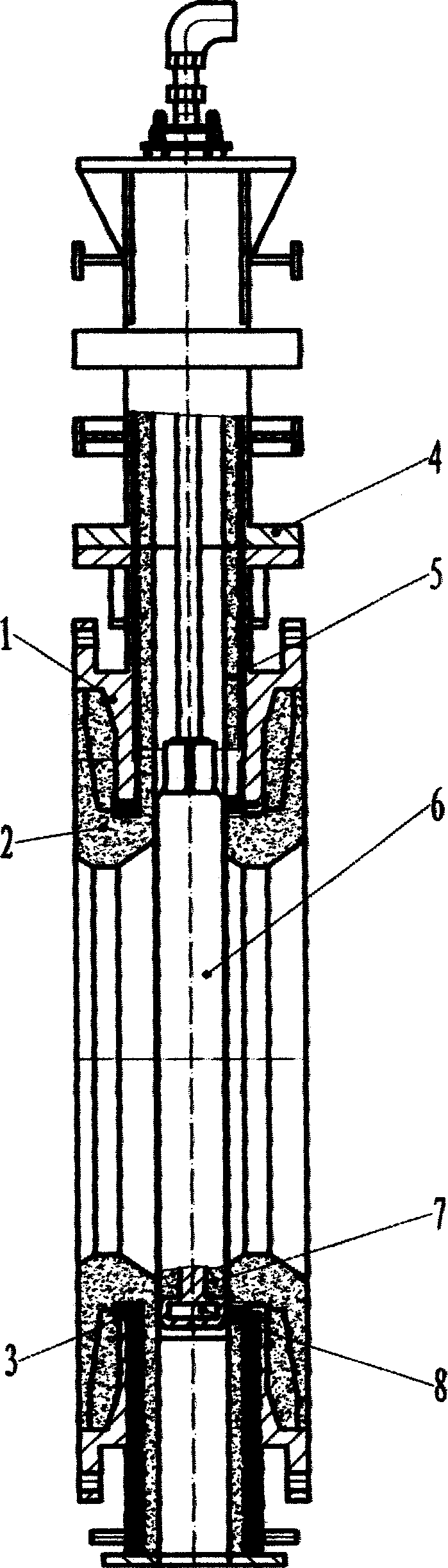

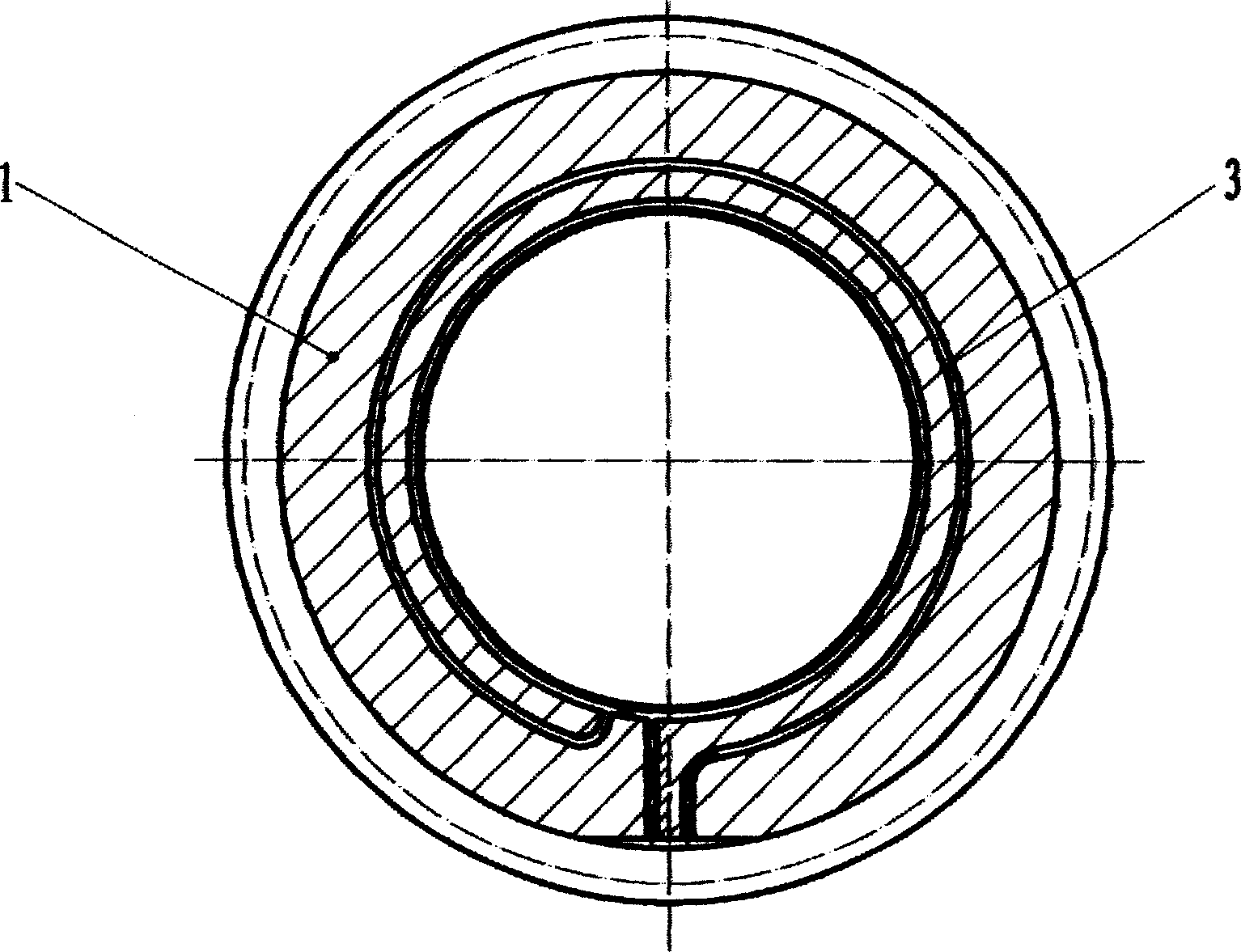

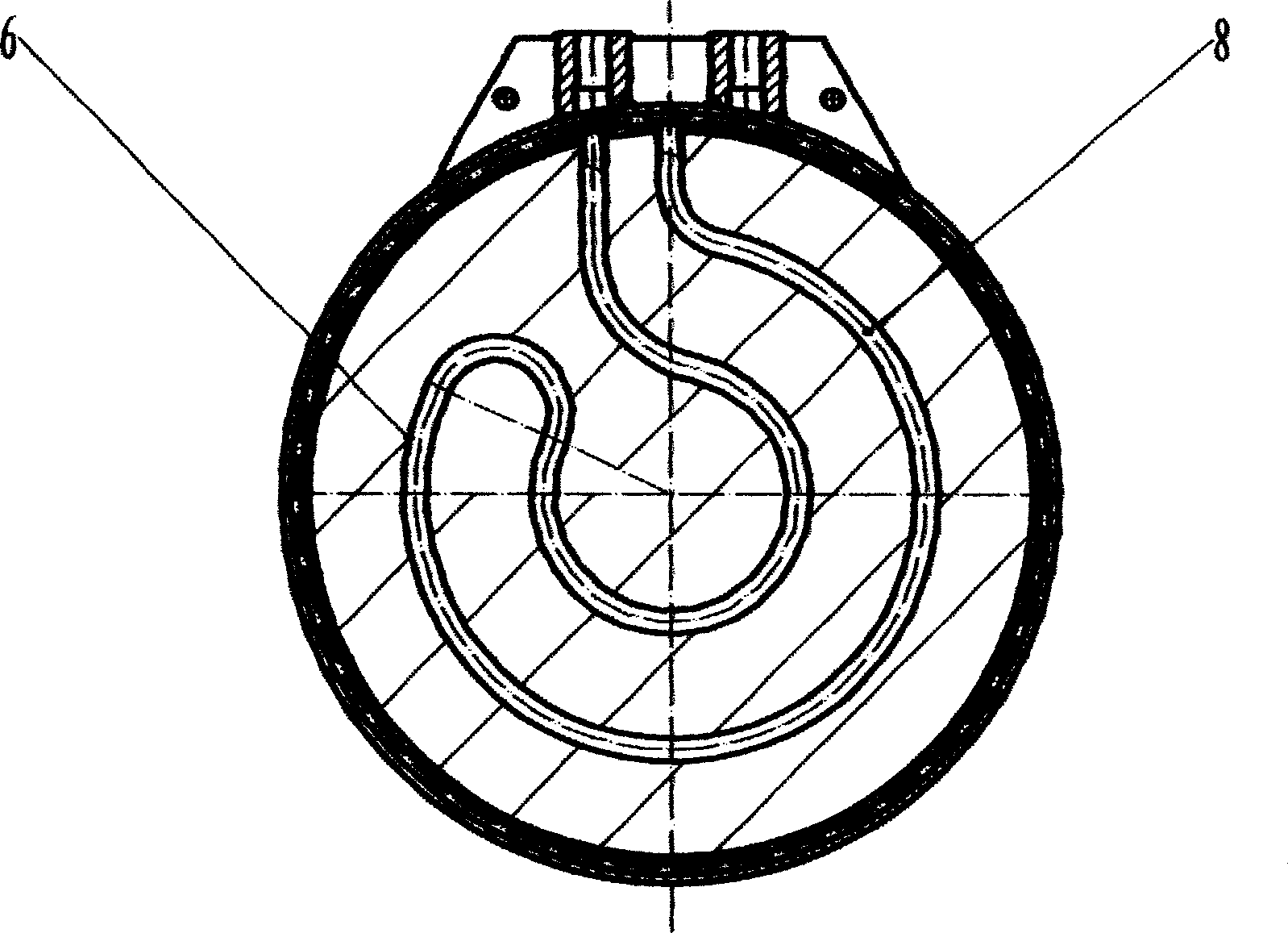

[0012] As shown in the figure: the micro-water energy-saving hot air valve is composed of a valve body, a valve cover and a valve plate. The valve body and the left and right large flange shells (1) are layered with refractory linings (2) covering layers, and the cooling water pipes (3) on the sealing surfaces of the left and right large flanges are made of buried pipe castings or steel plate machined waterway parts. The bonnet casing (4) is also covered with a layered cast refractory lining (5). The two symmetrical surfaces of the outer layer of the valve plate body (6) are covered with a layered cast refractory lining (7), and the inner cooling water pipeline (8) is a buried pipe casting or a steel plate machined water channel part.

[0013] The layered cast refractory lining cover used in the valve body, bonnet and valve plate, the thermal insulation layer can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com