Defects detection method and apparatus for optical components

A technology for detecting optical components and defects, which is applied in the direction of optical testing defects/defects, testing of machines/structural components, measuring devices, etc. Problems such as the state of light emission, to achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

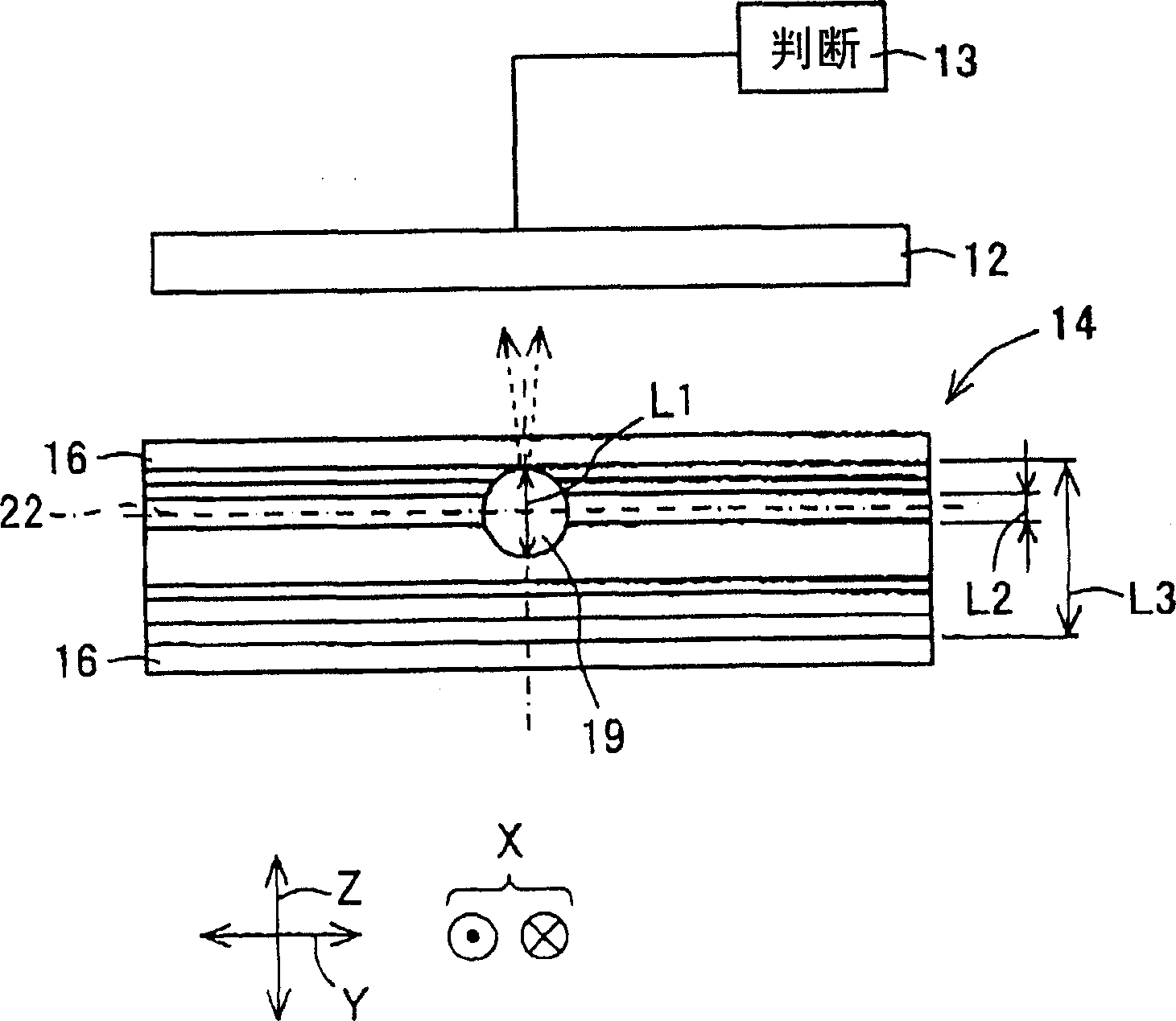

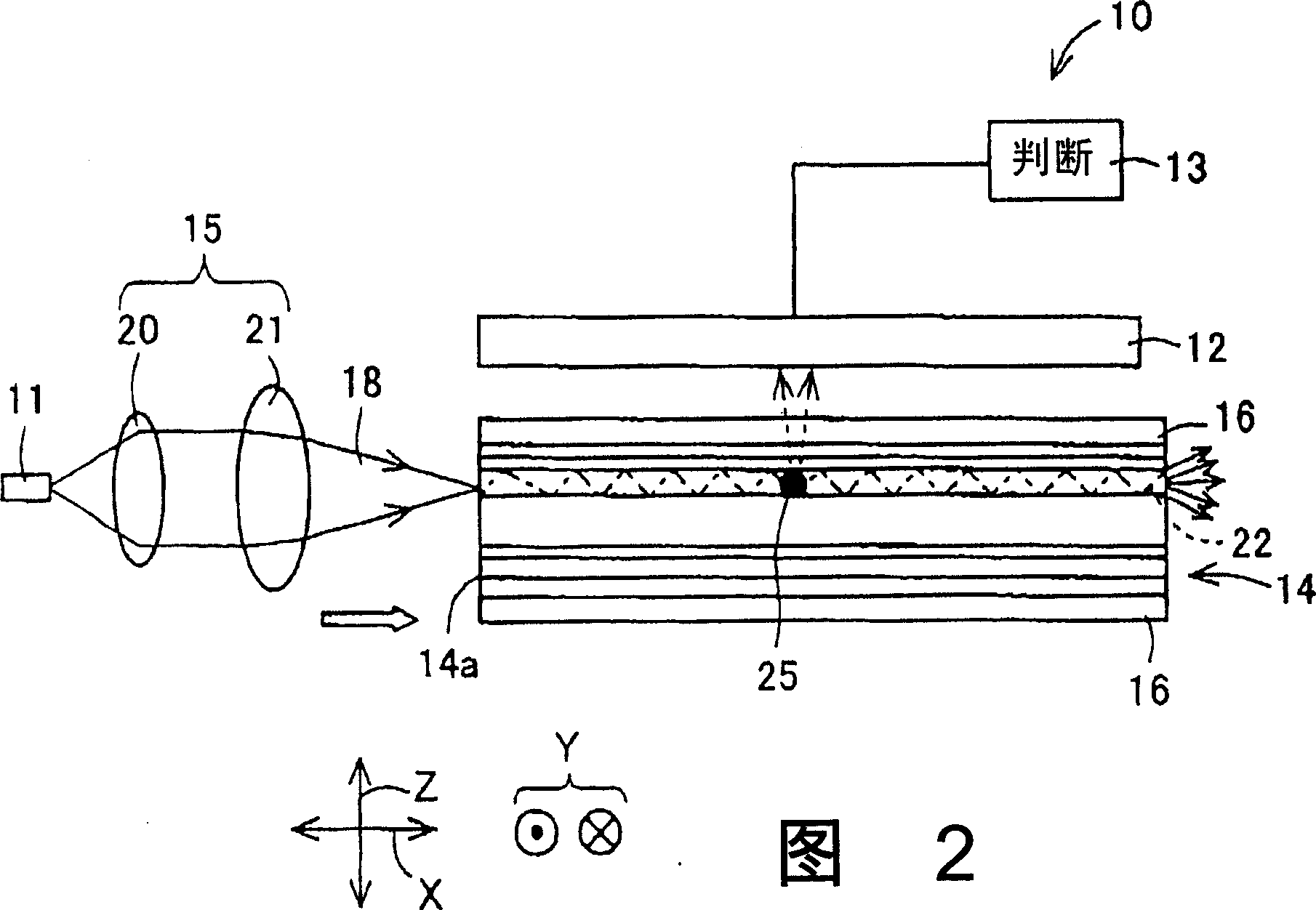

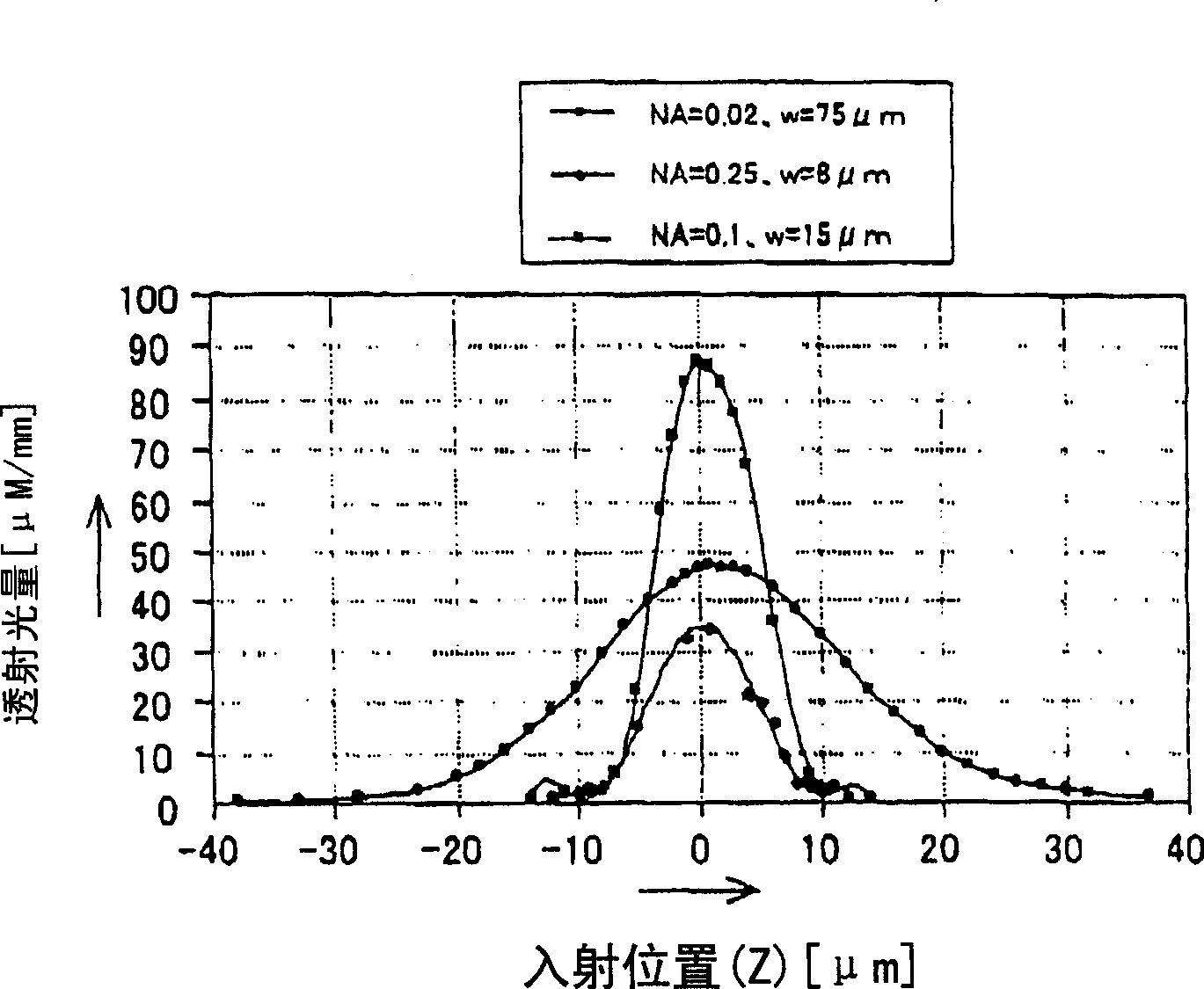

[0107] figure 1 It is a front view showing a part of an optical component defect inspection device 10 according to an embodiment of the present invention. FIG. 2 is a side view showing the optical component defect inspection device 10 . The composition of the optical component defect inspection device (hereinafter sometimes simply referred to as "defect inspection device") 10 includes a laser light source 11 , a light detection unit 12 , a judgment unit 13 and an incident unit 15 . The defect inspection device 10 detects a defect 25 in the optical component 14 formed by laminating a plurality of transmissive layers.

[0108] The optical member 14 is made of various materials, and in this embodiment, a plurality of sheet-like materials with different thickness dimensions are stacked in the thickness direction to form a multilayer struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com