Air-vapor coupling vapor exploding ephedrine wall breaking method

An extraction method and technology of ephedrine, applied in the field of air-steam coupled steam explosion wall-breaking extraction, can solve the problems of low utilization rate of raw materials, waste of ephedra resources, environmental pollution, etc., and achieve the goal of protecting traditional Chinese medicine components, improving utilization rate, and increasing extraction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

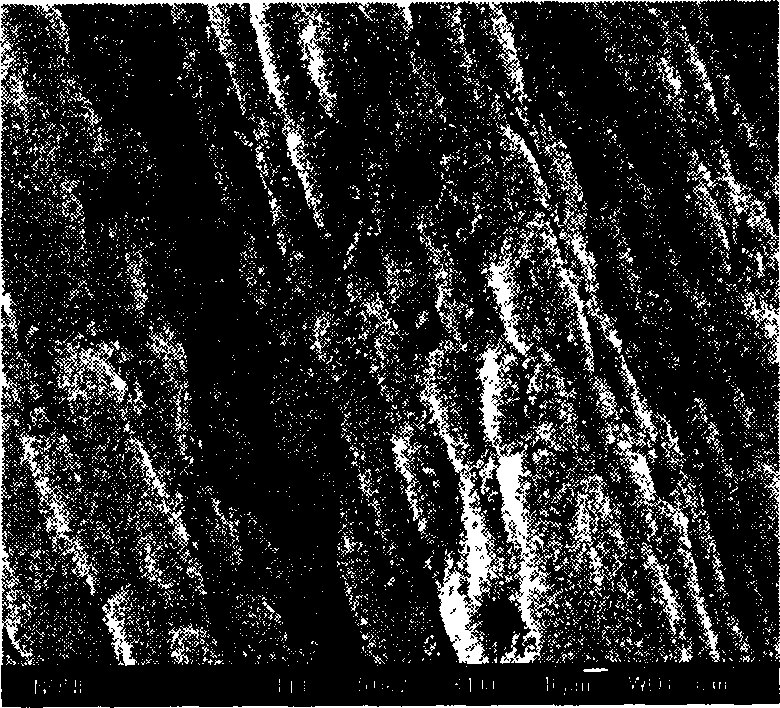

[0020] Embodiment 1, extracting ephedrine step with the method of the present invention is as follows:

[0021] 1) Put the ephedra grass material roughly cut to a length of 20-30mm into the steam explosion tank, use air and water vapor as the steam explosion medium, and first feed air until the pressure in the steam explosion tank is 5kg / cm 2 , and then quickly inject steam until the pressure inside the steam explosion tank is 10kg / cm 2 , steam explosion treatment for 20 minutes, then immediately open the discharge ball valve, so that the ephedra material is sprayed into the normal pressure release tank;

[0022] 2) The ephedra grass material after the pretreatment of air-steam coupling steam explosion wall breaking is extracted by immersion in water for 3 times, the weight ratio of grass and water is = 1:8, the extraction temperature is 80°C, and the extraction time is 120min . The extraction rate of ephedrine of the present embodiment is 78.06%.

Embodiment 2

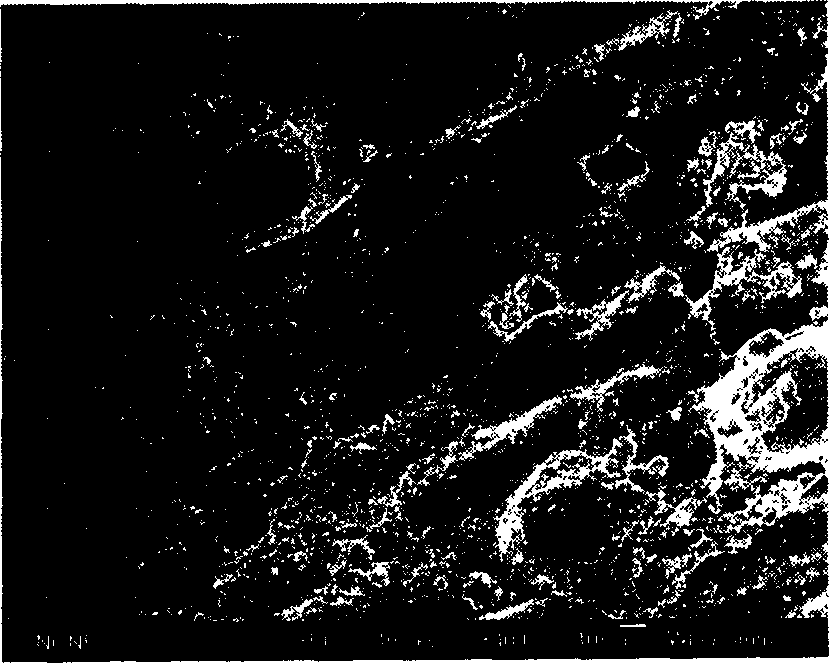

[0023] Embodiment 2, extract ephedrine step as follows with the method of the present invention:

[0024] 1) Put the ephedra grass material roughly cut to a length of 20-30mm into the steam explosion tank, use air and water vapor as the steam explosion medium, and first feed air until the pressure in the steam explosion tank is 8kg / cm 2 , and then quickly inject steam until the pressure inside the steam explosion tank is 12kg / cm 2 , steam explosion treatment for 2 minutes, then immediately open the discharge ball valve, so that the ephedra material is sprayed into the normal pressure release tank;

[0025] 2) The ephedra grass material after the pretreatment of air-steam coupled steam explosion wall breaking is extracted by 4 times of water immersion, the weight ratio of the grass and water is = 1:12, the extraction temperature is 100 ° C, and the extraction time is 30 minutes . The ephedrine extraction rate of the present embodiment is 80.56%.

Embodiment 3

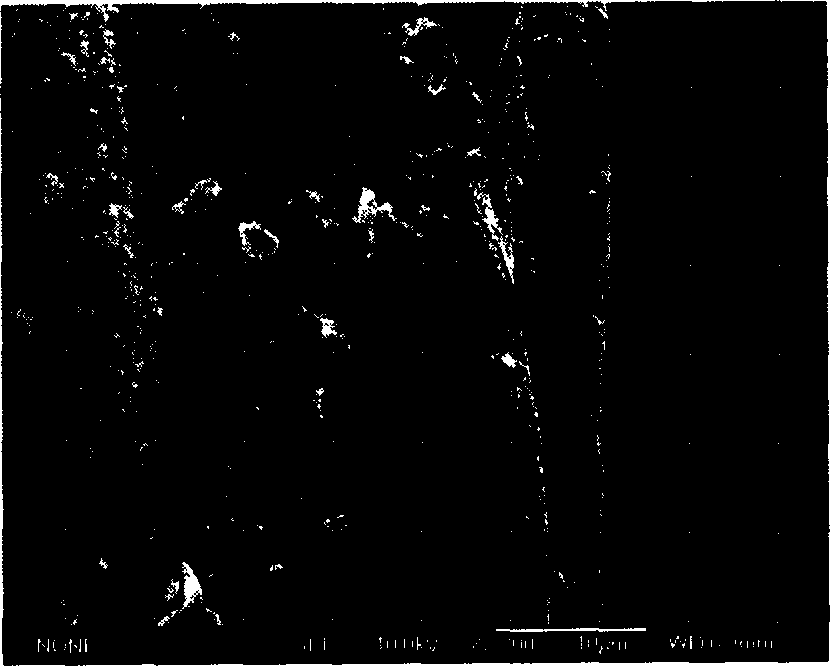

[0026] Embodiment 3, extract ephedrine step as follows with the method of the present invention:

[0027] 1) Put the ephedra grass material roughly cut to a length of 20-30mm into the steam explosion tank, use air and water vapor as the steam explosion medium, and first feed air until the pressure in the steam explosion tank is 8kg / cm 2 , and then quickly inject steam until the pressure inside the steam explosion tank is 15kg / cm 2 , steam explosion treatment for 3 minutes, then immediately open the discharge ball valve, so that the ephedra material is sprayed into the normal pressure release tank;

[0028] 2) The ephedra grass material after the pretreatment of air-steam coupling steam explosion wall breaking is extracted by immersion in water three times, the weight ratio of grass and water is = 1:10, the extraction temperature is 100°C, and the extraction time is 120min . The extraction rate of ephedrine of the present embodiment is 91.3% (the extraction rate of once extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com