Jet type gas-solid separating device

A gas-solid separation and jet-type technology, applied in the field of thick-lean separation technology and equipment, can solve the problem of stable combustion, high efficiency, anti-slagging, anti-high temperature corrosion of unfavorable swirl burners, increase the operating cost of power plant boilers, and reduce the safety of boiler operation In order to achieve the effect of improving combustion efficiency and stable combustion characteristics, occupying a small space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

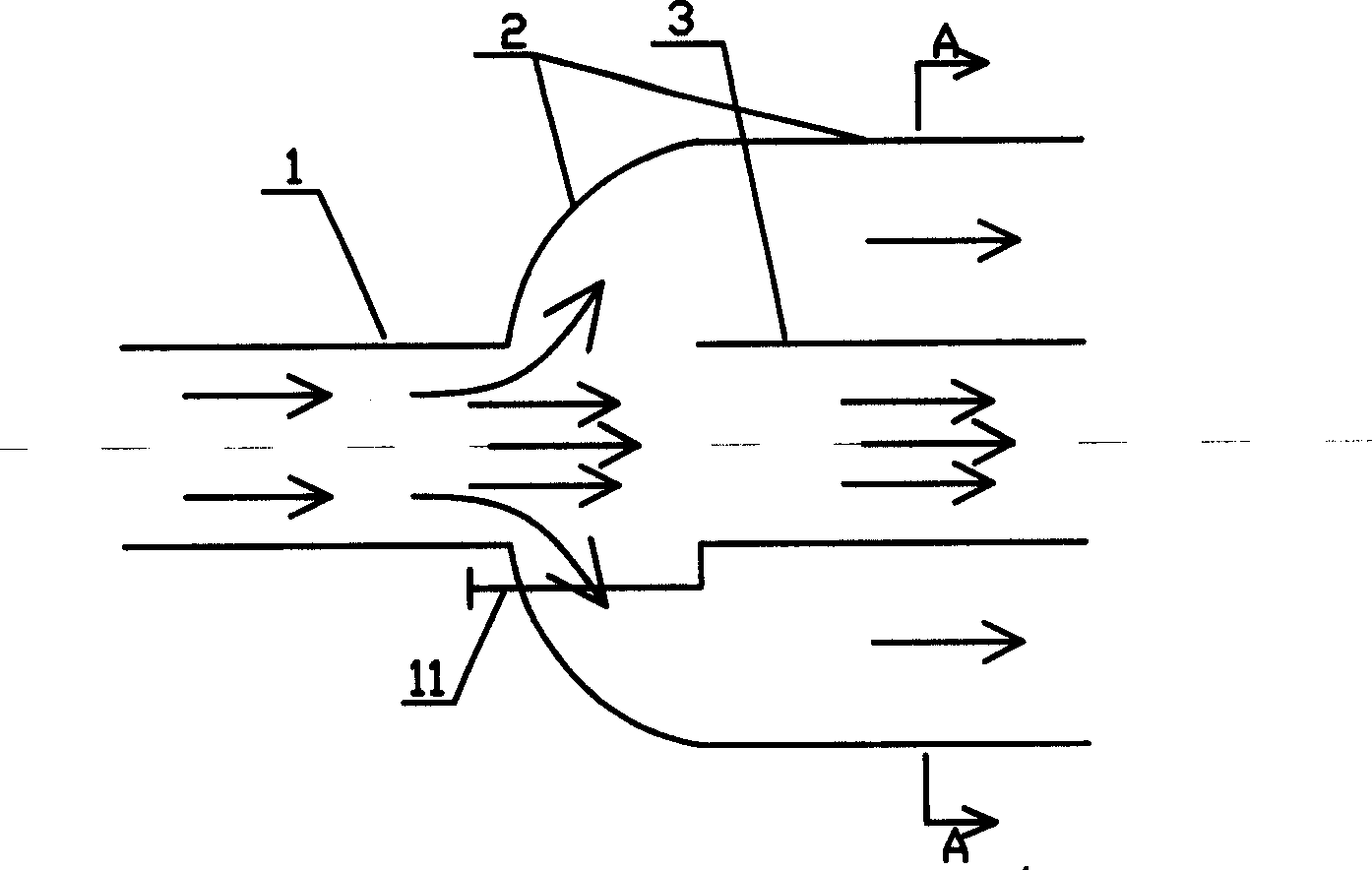

[0020] Below in conjunction with accompanying drawing, working principle, concrete structure and implementation of the present invention are further described:

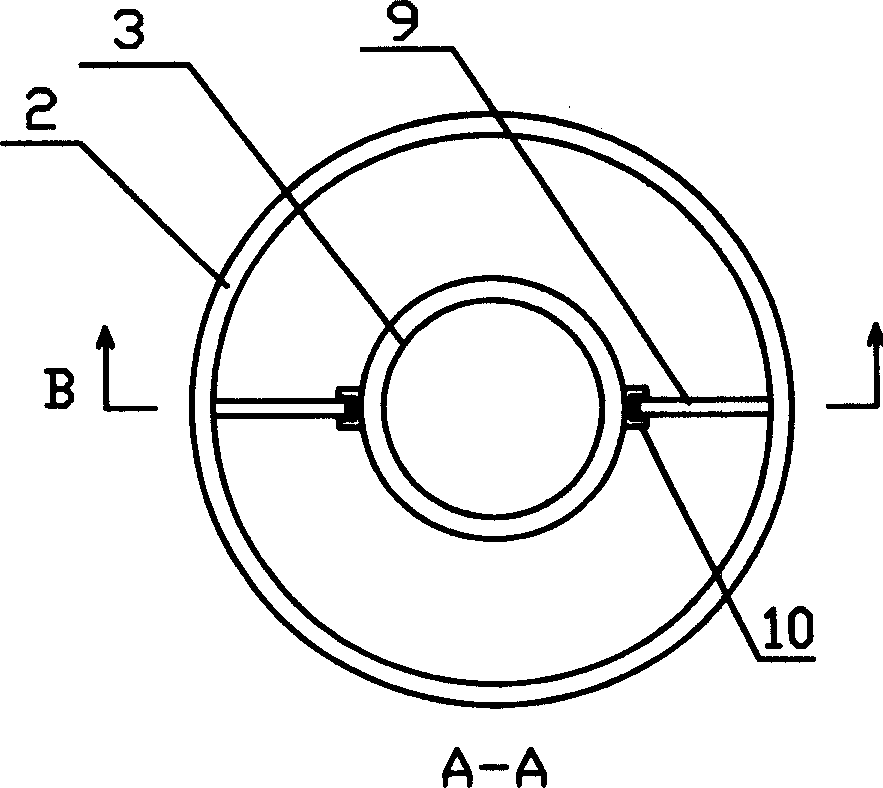

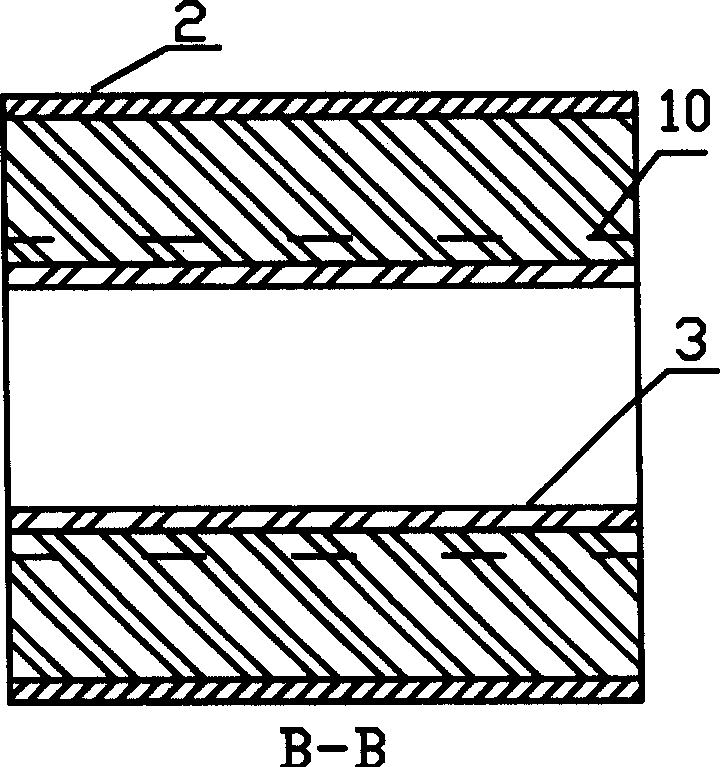

[0021] According to the inertia difference of different phases in the gas-solid two-phase flow, the jet flow generated by the expansion pipe section is used to separate the gas-solid two-phase fluid from thick to thin, and the large solid particles are enriched in the center of the jet flow, while the gas phase and some small particles expand to the surroundings. The thick strands in the fluid jetted out from the primary straight pipe section 1 through the expansion pipe section 2 will be collected by the core pipe 3, while the light strands will be collected by the annular channel between the core pipe and the expansion pipe section.

[0022] figure 1 It is a schematic diagram of the structural principle of an embodiment provided by the present invention. It consists of a primary straight pipe section 1, an expanded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com