Magnetic recording medium and magnetic recording and reproduction apparatus

一种磁记录介质、记录层的技术,应用在磁记录、磁记录层、数据记录等方向,能够解决磁空间大、记录/再现特性恶化、可靠性问题等问题,达到面记录密度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

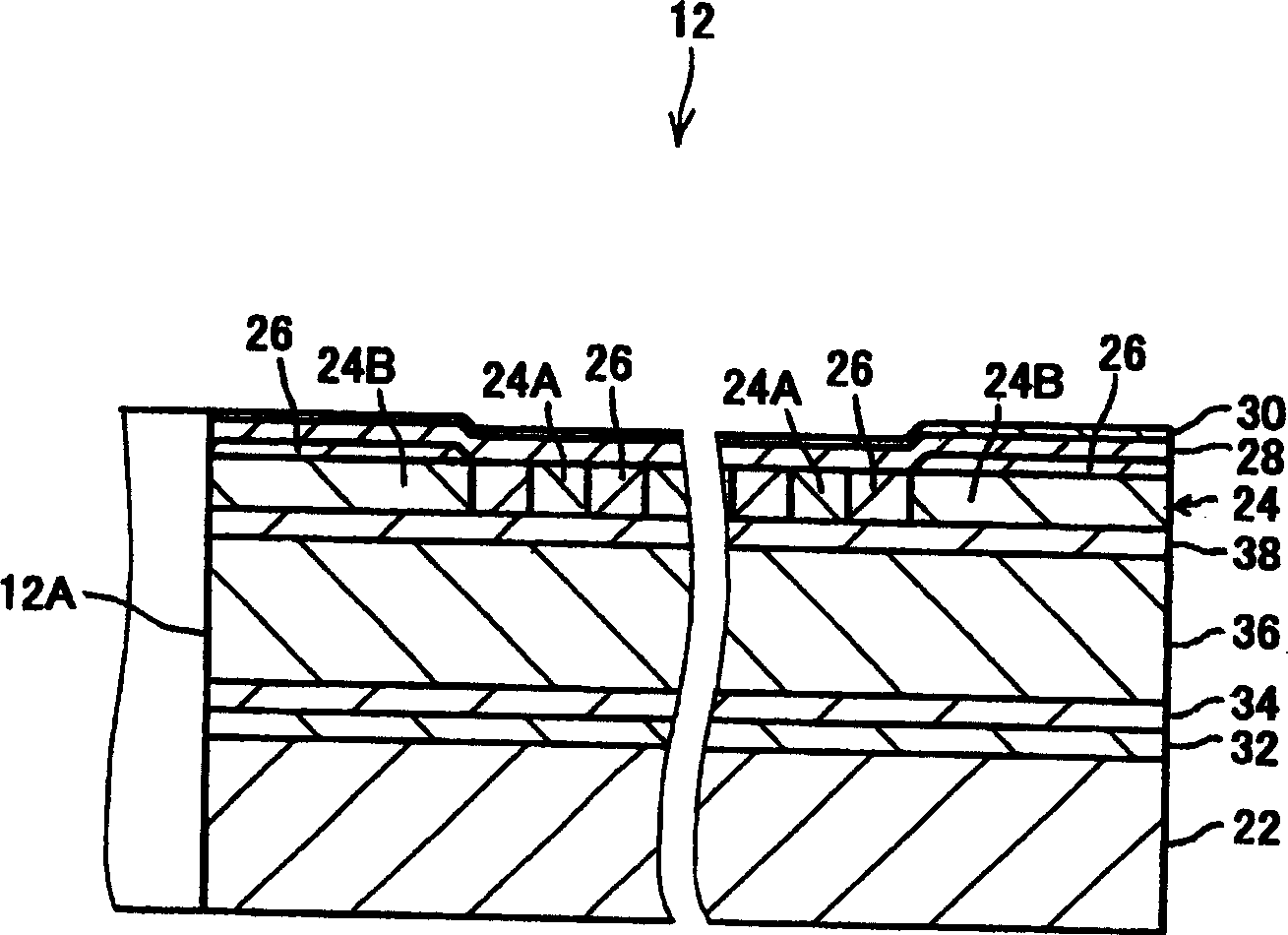

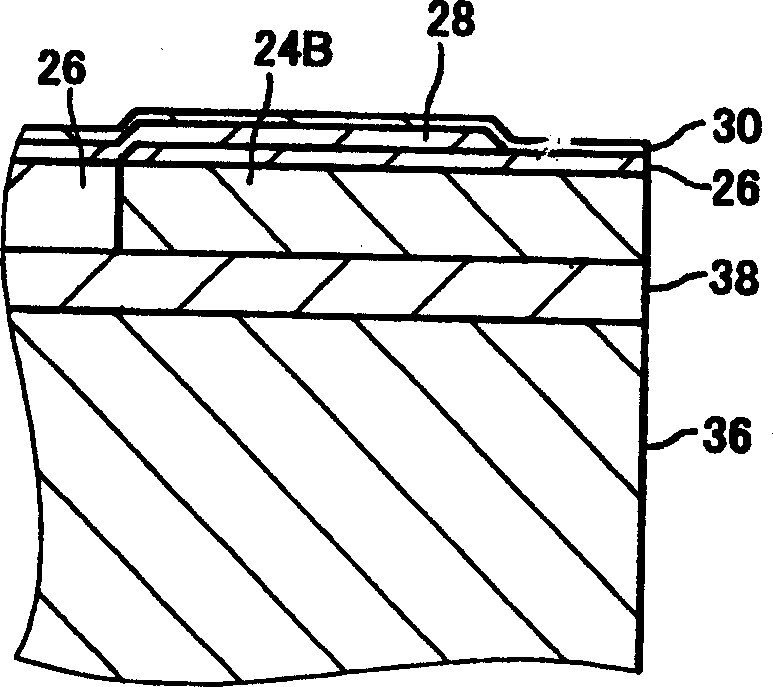

[0066] While the magnetic recording medium 12 of the first embodiment has a center hole 12A, the magnetic recording medium 50 of the third embodiment has a disc shape without a center hole, and a disc-shaped non-recording element 24B is formed in the center. The diameter of the non-recording element 24B in the central portion is 200 to 3000 μm. As for other structures, since they are the same as those of the above-mentioned magnetic recording medium 10, they are given the same figure 2 with image 3 The same reference numerals are used and descriptions are omitted. In addition, reference sign CL in the figure represents the central axis of the magnetic recording medium 50 .

[0067] Thus, even in the magnetic recording medium 50 without a central hole, by forming the non-magnetic material 26 in the form of covering the non-recording element 24B, in the case where the thickness of the protective layer 28 is insufficient on the non-recording element 24B, the portion The unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com