Large-diameter seamless steel pipe sizing-reducing mill

A technology of seamless steel pipe, fixed and reduced diameter, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., to achieve the effect of reducing volume, convenient installation, and saving manufacturing and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation will be described below in conjunction with the accompanying drawings.

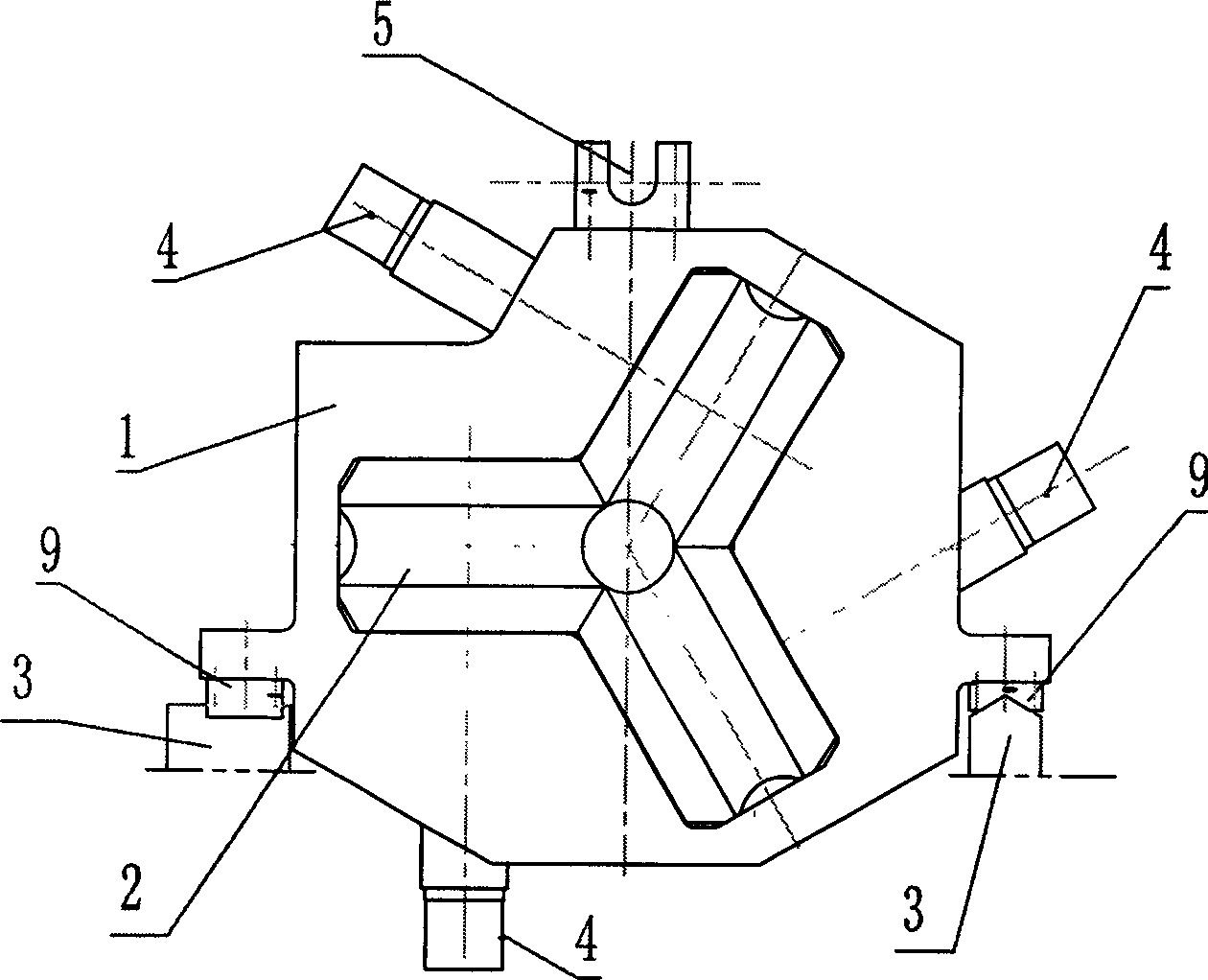

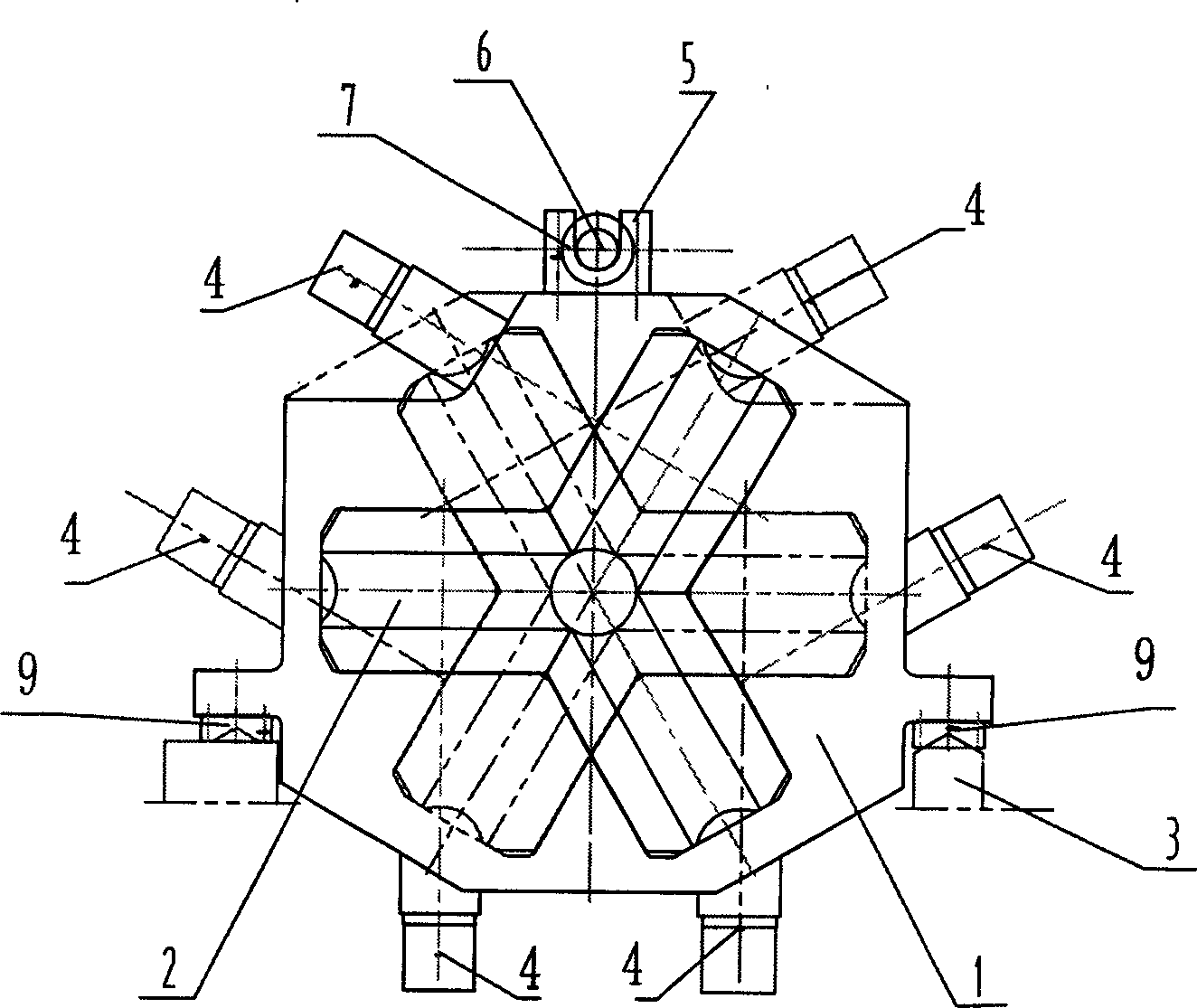

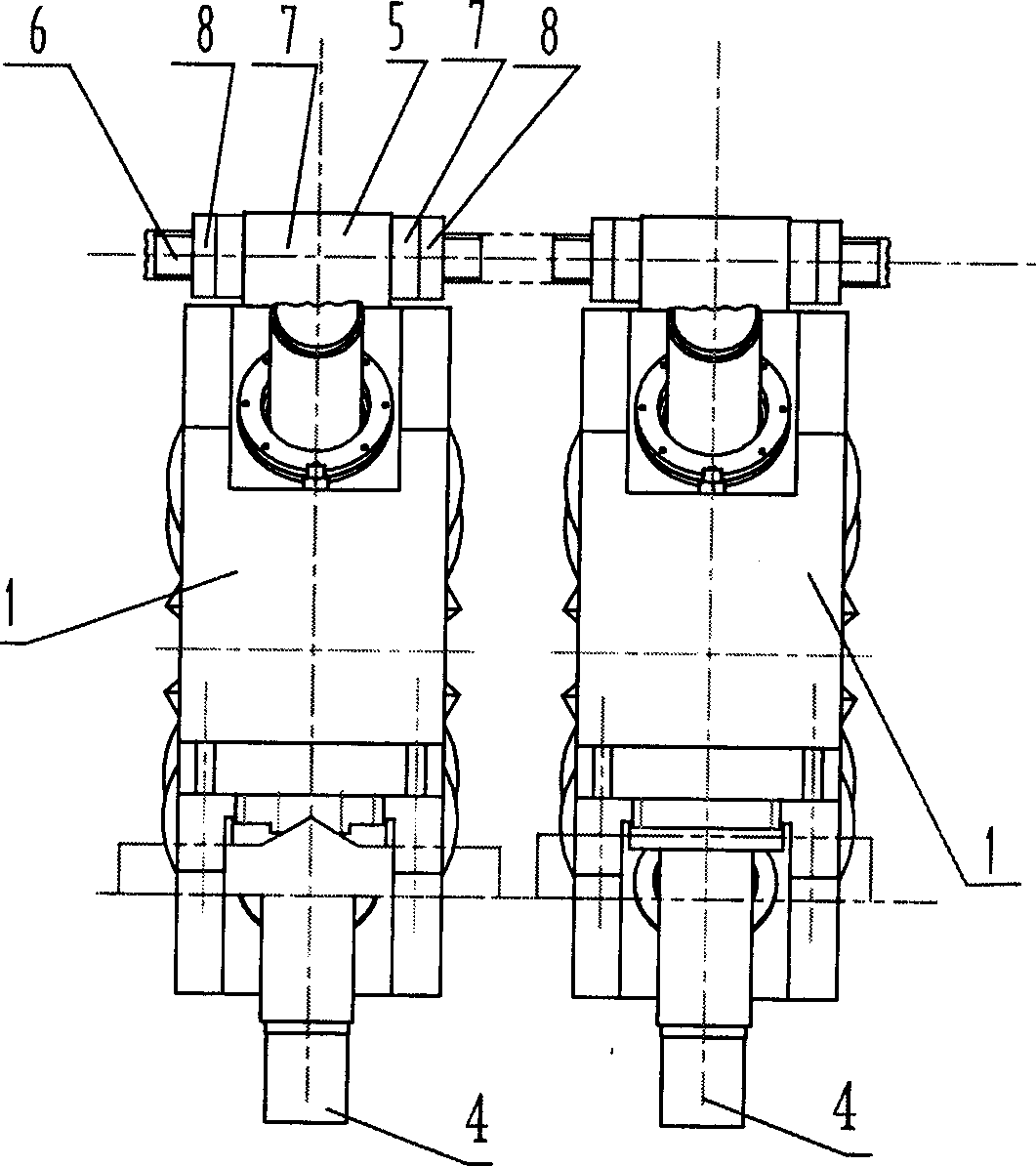

[0018] figure 1 Shown, a large diameter seamless steel pipe sizing machine. It includes at least two racks 1 and rolls 2 arranged along the steel pipe rolling direction, and a transmission device. The basic guide rail 3 is a V-shaped guide rail, and the basic guide rail under each frame is composed of two mutually perpendicular basic guide rails parallel to the rolling direction of the steel pipe and perpendicular to the rolling direction of the steel pipe; The direction corresponds to the V-shaped positioning groove 9; the V-shaped groove is directly located on two mutually vertical basic guide rails, and the frame and the V-shaped groove are fixed on the basic guide rails with bolts and nuts, and each frame is connected together. There are three rolls in each frame, and the rolls have bearings and are installed in the frame, each roll is connected with the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com