Angular contact ball bearing outer ring groove position instrument measuring method

An angular contact ball bearing and groove position technology, applied in instruments, measuring devices, etc., can solve the problems of slow detection process, cumbersome operation, large light transmission gap, etc., to achieve simple and easy operation, fast and accurate measurement, and simplified operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

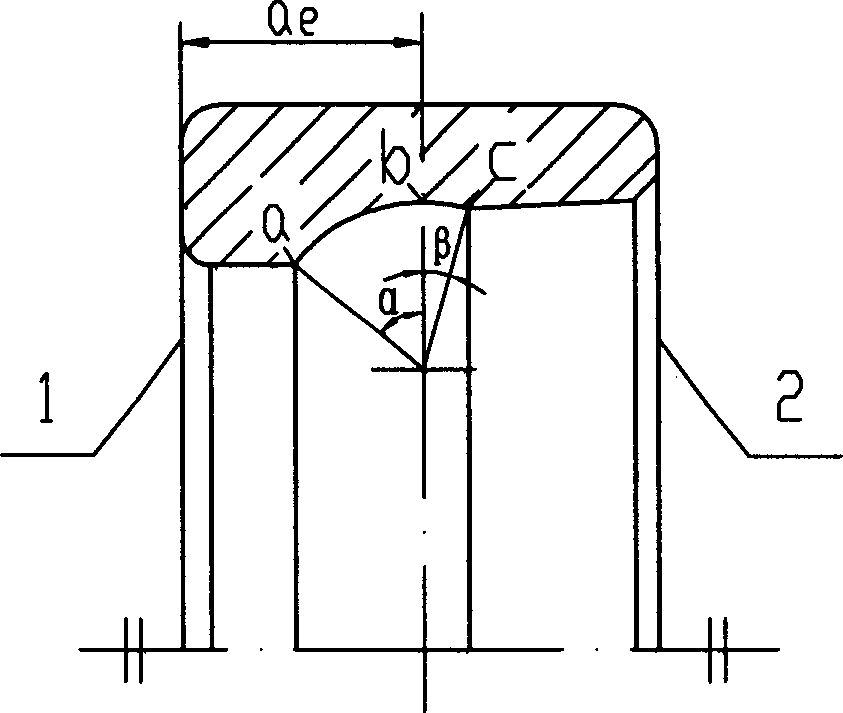

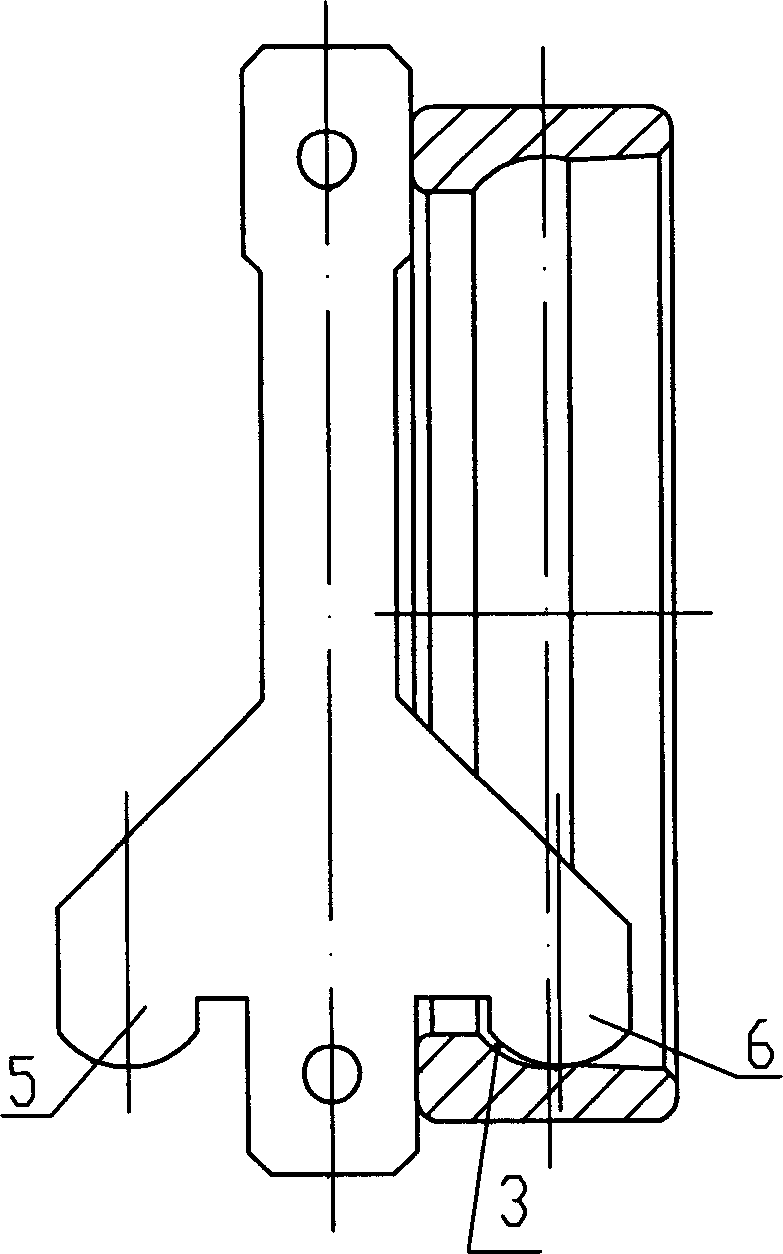

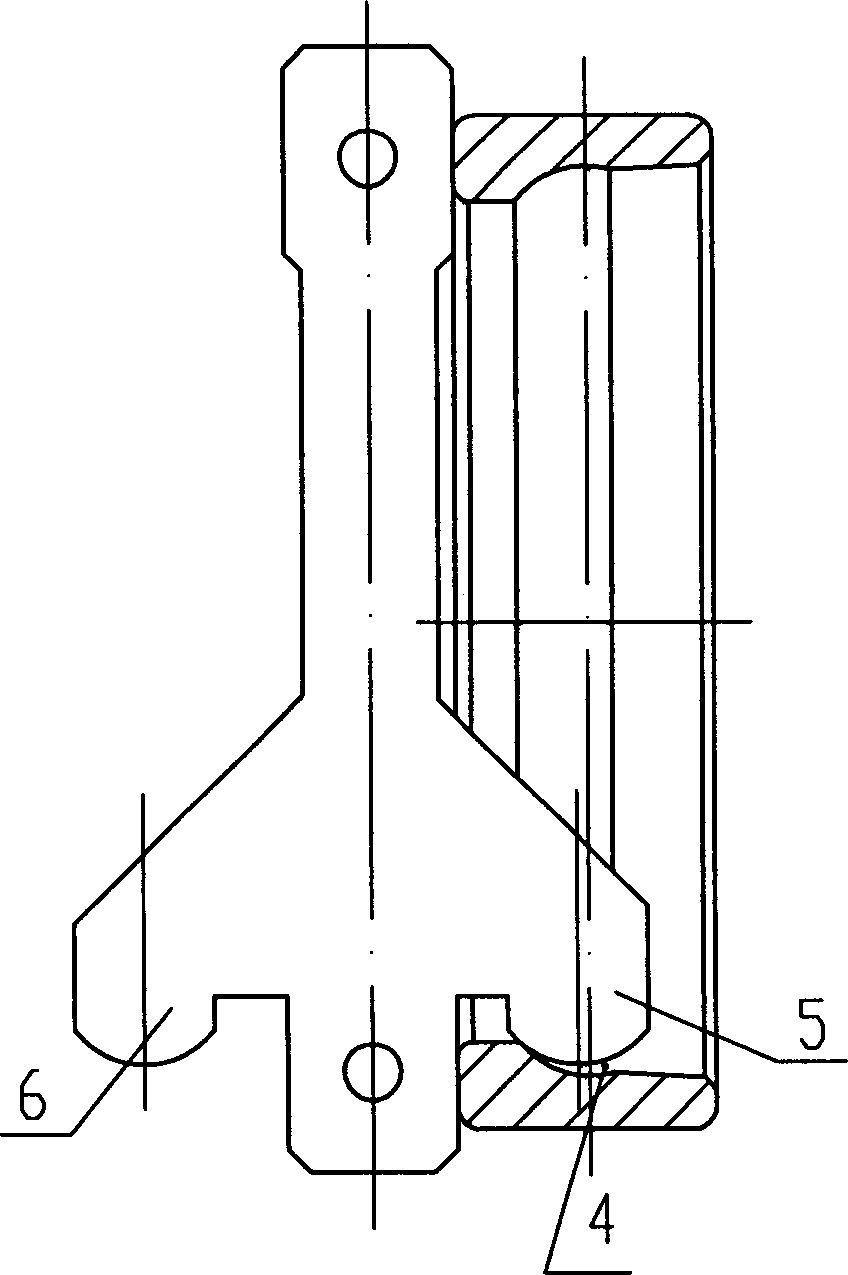

[0033] Now pre-processing the outer ring groove of angular contact ball bearing of model 7308EACM / 01, product height dimension C=23mm, groove curvature Re=R7.92mm, groove diameter dimension De=φ80.694mm, groove position a e =11.62±0.03. It is necessary to measure the groove position of the outer ring of the angular contact ball bearing with an instrument.

[0034] Measurement method of the present invention comprises the following steps:

[0035] 1. Selection and calculation of ditch position standard parts

[0036] Choose the finished outer ring of 6308E / 01 deep groove ball bearing corresponding to 7308EACM / 01, its height dimension is also C=23mm, groove curvature Re=R7.92mm, groove diameter size De=φ80.594mm, can be used as 7308EACM Candidates for / 01 groove position standard parts.

[0037] (1) Select 4 finished outer rings of 6308E / 01. The plane parallel difference and outer groove swing of the selected parts are both ≤2μm. This requirement is mainly used to reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com